Method for continuously producing biological butanol by fermentation, separation and coupling of static bed

A technology of fermentation separation coupling and biobutanol, which is applied in the field of continuous production of biobutanol through fixed bed fermentation separation coupling, can solve problems such as low production efficiency of biobutanol, improve solvent production rate, prolong membrane operation time and life, The effect of efficient continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Using glucose as raw material to ferment butanol, the composition of fermentation medium: glucose 60g / L, corn steep liquor 1g / L, potassium dihydrogen phosphate 0.5g / L, dipotassium hydrogen phosphate 0.5g / L, manganese sulfate monohydrate 0.01g / L L, sodium chloride 0.01g / L, magnesium sulfate heptahydrate 0.2g / L, ammonium acetate 2g / L, thiamine 1mg / L, initial pH 6.0.

[0027] The bagasse crushed to a length of 2-3 cm was treated with 68% (w / w) concentrated nitric acid for 4 hours, filled in the fixed bed 1 as an immobilization medium, and steam sterilized for later use.

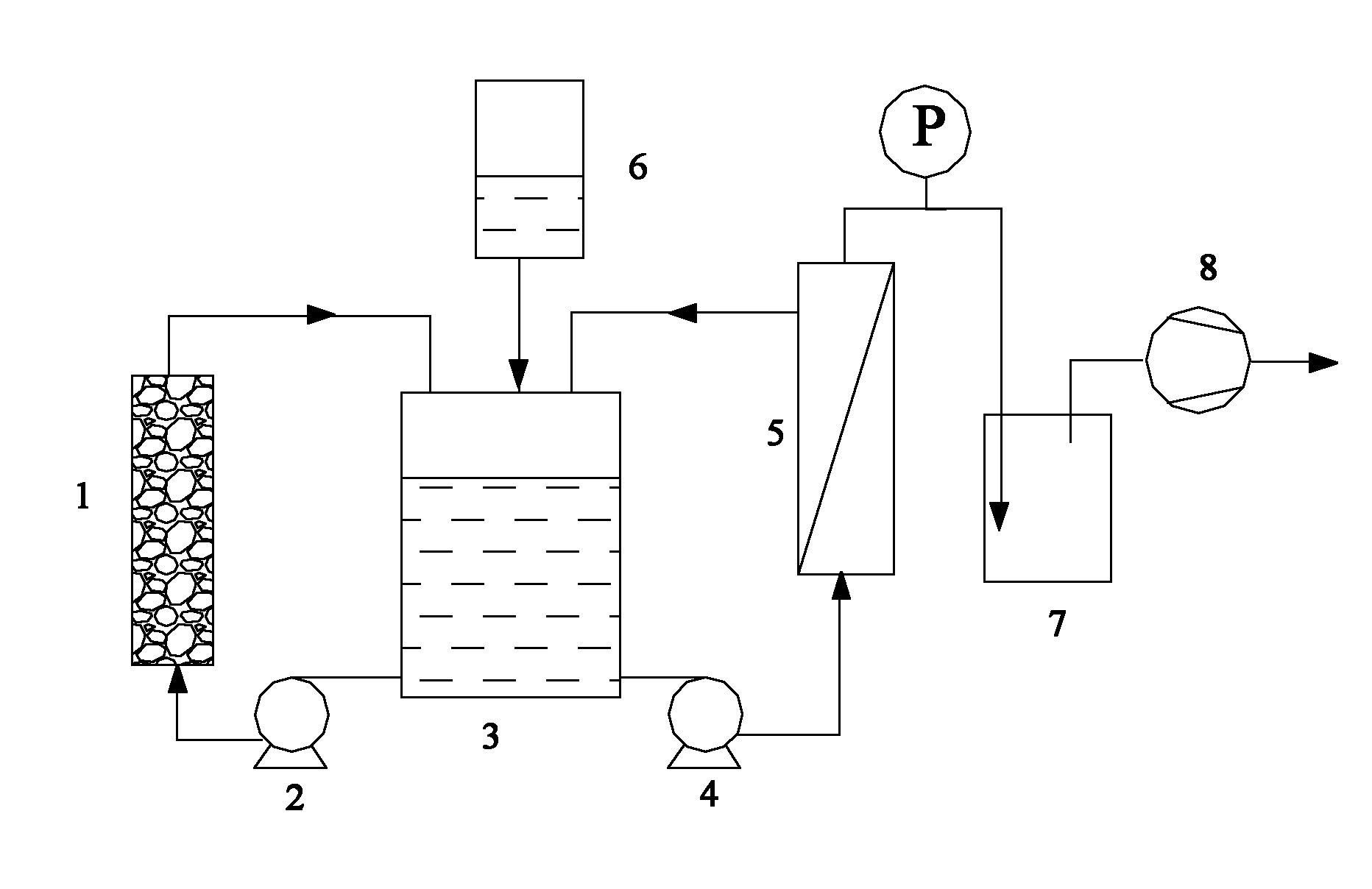

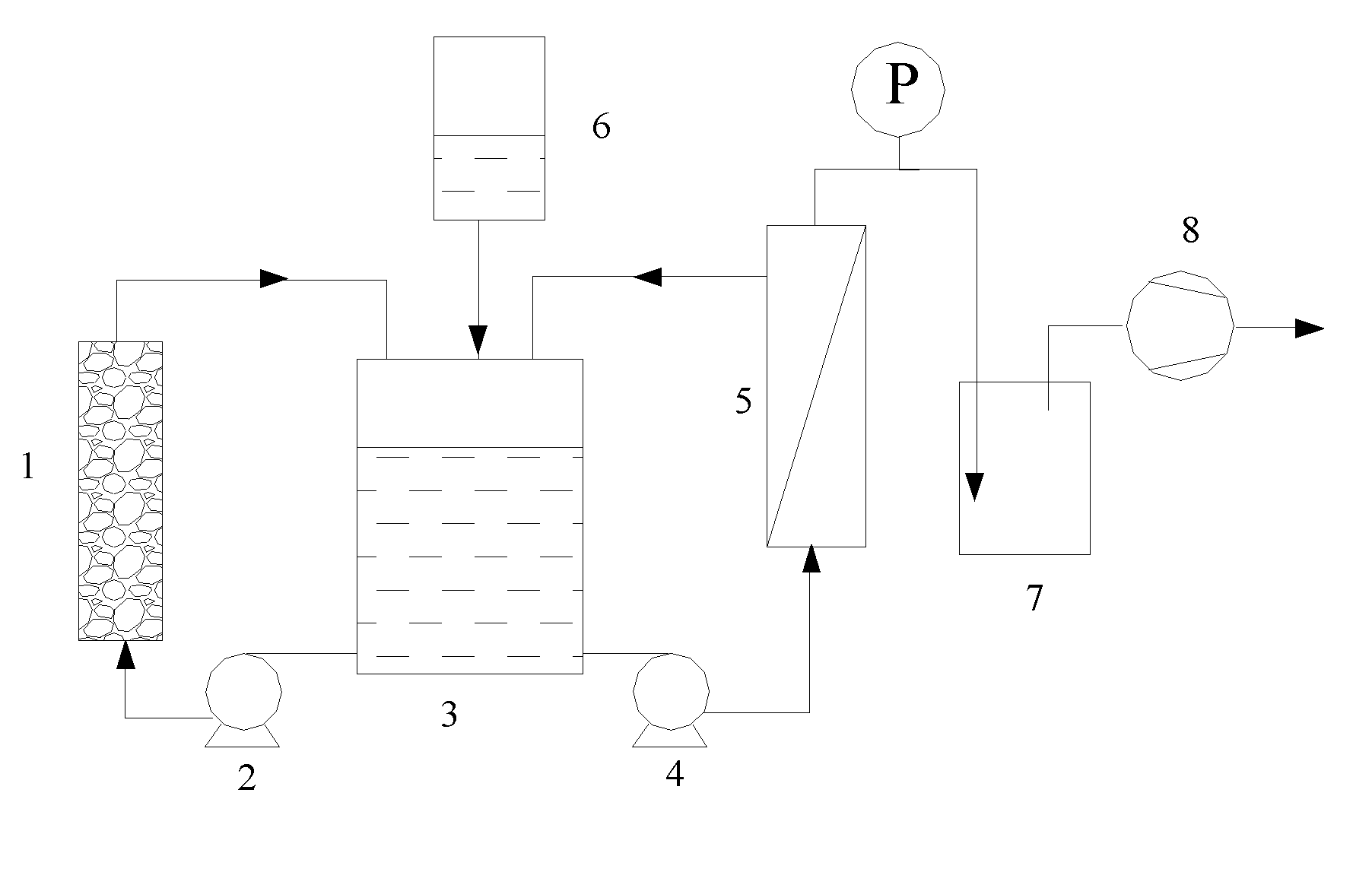

[0028]After the fermentation medium is steam sterilized and cooled, the bioreactor 3 is connected to the fixed bed 1, the medium is passed into the fixed bed 1 through the pump 2 and circulated back to the bioreactor 3, and the circulation is stopped after passing through sterile nitrogen for 30 minutes, and the inoculation Alcohol-producing strain Clostridium acetobutylicum 1.134 (http: / / www.cgmcc.net / in...

Embodiment 2

[0030] Corn flour is used as raw material to ferment butanol, and the composition of the fermentation medium is as follows: the concentration of corn flour saccharification liquid is 40g / L, potassium dihydrogen phosphate is 0.5g / L, dipotassium hydrogen phosphate is 0.5g / L, and p-aminobenzoic acid is 0.005g / L, initial pH5.5.

[0031] After the zeolite filter material with a diameter of 0.5-1 cm is treated with 0.1 mol / L ferric chloride for 5 hours, it is filled in the fixed bed 1 as an immobilization medium, and it is used after steam sterilization.

[0032] After the fermentation medium is steam sterilized and cooled, the bioreactor 3 is connected to the fixed bed 1, and the medium is passed into the fixed bed 1 through the pump 2 and circulated back to the bioreactor 3, and the circulation is stopped after 20 minutes of sterile nitrogen gas, and the inoculation The alcohol-producing strain Clostridium acetobutylicum ATCC 824, under anaerobic conditions, the fermentation temp...

Embodiment 3

[0034] Butanol is prepared by fermenting the multi-component sugar solution of corn cobs hydrolyzed by dilute acid. L, yeast powder 1g / L, ferrous sulfate heptahydrate 0.01g / L, manganese sulfate monohydrate 0.01g / L, biotin 0.1mg / L, initial pH 5.8.

[0035] Activated carbon fibers were treated with 80% (w / w) concentrated sulfuric acid for 3 hours, and then treated with 0.1mol / L ferric chloride for 6 hours, filled in fixed bed 1 as the immobilization medium, and chemically treated with 1mol / L sodium hydroxide solution. Ready to use after disinfection.

[0036] After the fermentation medium is steam sterilized and cooled, the bioreactor 3 is connected to the fixed bed 1, the medium is passed into the fixed bed 1 through the pump 2 and circulated back to the bioreactor 3, and the circulation is stopped after passing through sterile nitrogen for 30 minutes, and the inoculation The alcohol-producing strain Clostridium beijerinckii ATCC 51743, under anaerobic conditions, the fermenta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com