Method for continuously producing biological butanol by fermentation, separation and coupling of static bed

A technology of fermentation separation coupling and bio-butanol, which is applied in the field of fixed-bed fermentation separation coupling continuous production of bio-butanol, can solve the problems of low production efficiency of bio-butanol, achieve the goal of increasing solvent production rate, weakening pollution, and reducing production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Using glucose as raw material to ferment butanol, the composition of fermentation medium: glucose 60g / L, corn steep liquor 1g / L, potassium dihydrogen phosphate 0.5g / L, dipotassium hydrogen phosphate 0.5g / L, manganese sulfate monohydrate 0.01g / L L, sodium chloride 0.01g / L, magnesium sulfate heptahydrate 0.2g / L, ammonium acetate 2g / L, thiamine 1mg / L, initial pH 6.0.

[0027] The bagasse crushed to a length of 2-3 cm was treated with 68% (w / w) concentrated nitric acid for 4 hours, filled in the fixed bed 1 as an immobilization medium, and steam sterilized for later use.

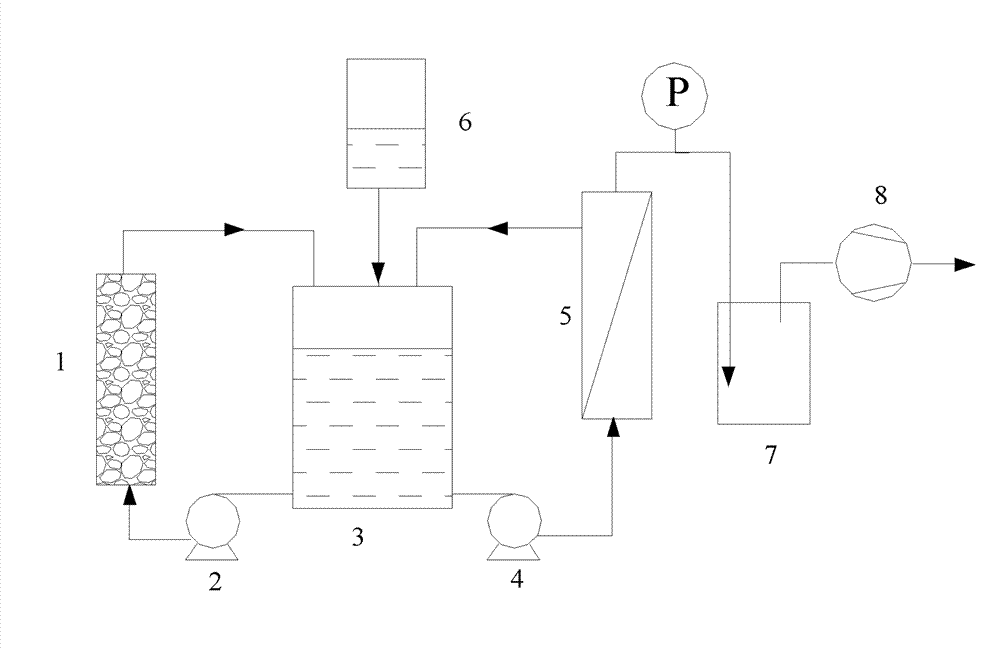

[0028]After the fermentation medium is steam sterilized and cooled, the bioreactor 3 is connected to the fixed bed 1, the medium is passed into the fixed bed 1 through the pump 2 and circulated back to the bioreactor 3, and the circulation is stopped after passing through sterile nitrogen for 30 minutes, and the inoculation Alcohol-producing strain Clostridium acetobutylicum 1.134 (http: / / www.cgmcc.net / in...

Embodiment 2

[0030] Corn flour is used as raw material to ferment butanol, and the composition of the fermentation medium is as follows: the concentration of corn flour saccharification liquid is 40g / L, potassium dihydrogen phosphate is 0.5g / L, dipotassium hydrogen phosphate is 0.5g / L, and p-aminobenzoic acid is 0.005g / L, initial pH5.5.

[0031] After the zeolite filter material with a diameter of 0.5-1 cm is treated with 0.1 mol / L ferric chloride for 5 hours, it is filled in the fixed bed 1 as an immobilization medium, and it is used after steam sterilization.

[0032] After the fermentation medium is steam sterilized and cooled, the bioreactor 3 is connected to the fixed bed 1, and the medium is passed into the fixed bed 1 through the pump 2 and circulated back to the bioreactor 3, and the circulation is stopped after 20 minutes of sterile nitrogen gas, and the inoculation The alcohol-producing strain Clostridium acetobutylicum ATCC 824, under anaerobic conditions, the fermentation temp...

Embodiment 3

[0034] Butanol is prepared by fermenting the multi-component sugar solution of corn cobs hydrolyzed by dilute acid. L, yeast powder 1g / L, ferrous sulfate heptahydrate 0.01g / L, manganese sulfate monohydrate 0.01g / L, biotin 0.1mg / L, initial pH 5.8.

[0035] Activated carbon fibers were treated with 80% (w / w) concentrated sulfuric acid for 3 hours, and then treated with 0.1mol / L ferric chloride for 6 hours, filled in fixed bed 1 as the immobilization medium, and chemically treated with 1mol / L sodium hydroxide solution. Ready to use after disinfection.

[0036] After the fermentation medium is steam sterilized and cooled, the bioreactor 3 is connected to the fixed bed 1, the medium is passed into the fixed bed 1 through the pump 2 and circulated back to the bioreactor 3, and the circulation is stopped after passing through sterile nitrogen for 30 minutes, and the inoculation The alcohol-producing strain Clostridium beijerinckii ATCC 51743, under anaerobic conditions, the fermenta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com