Graft modified polymer material and preparation method thereof

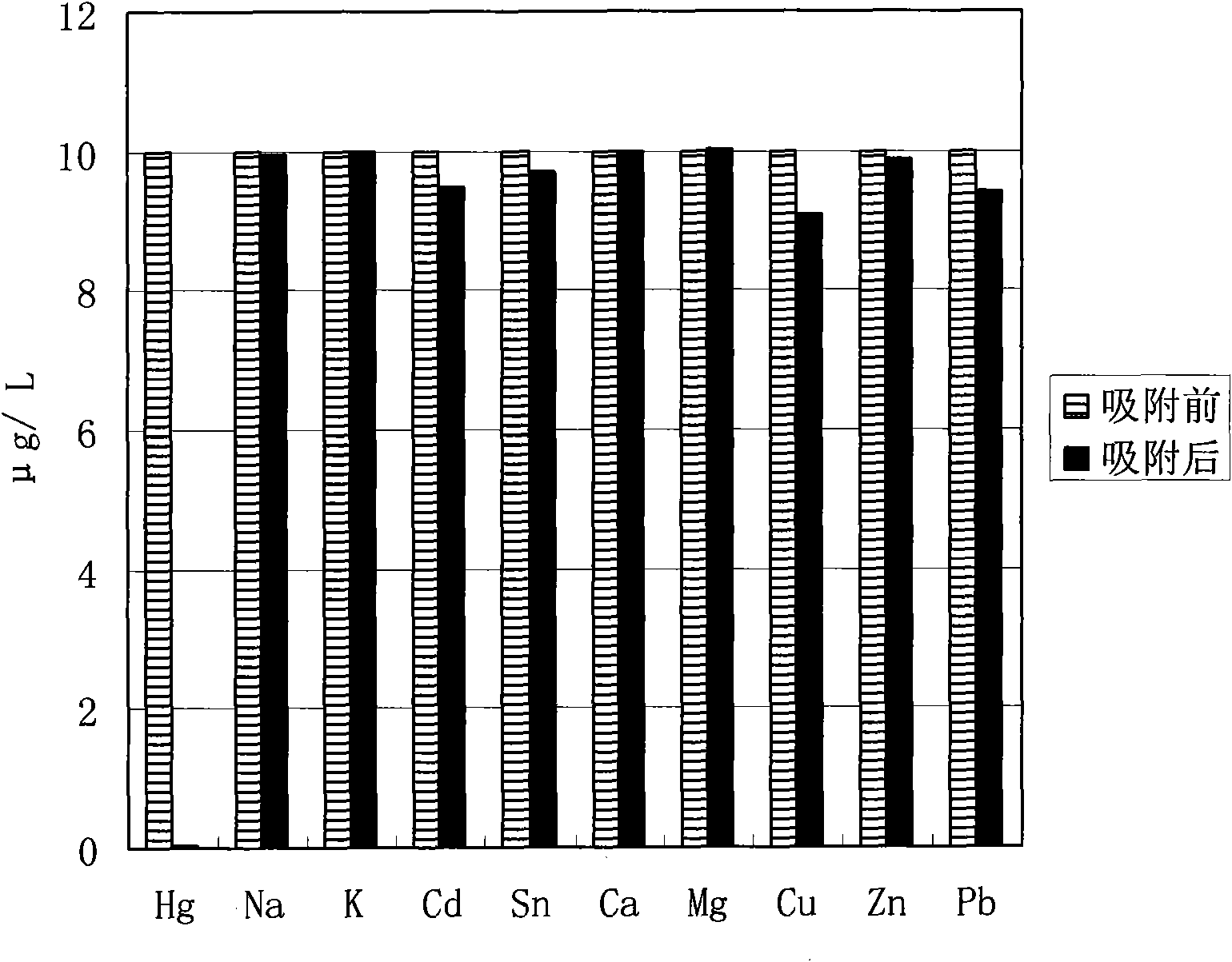

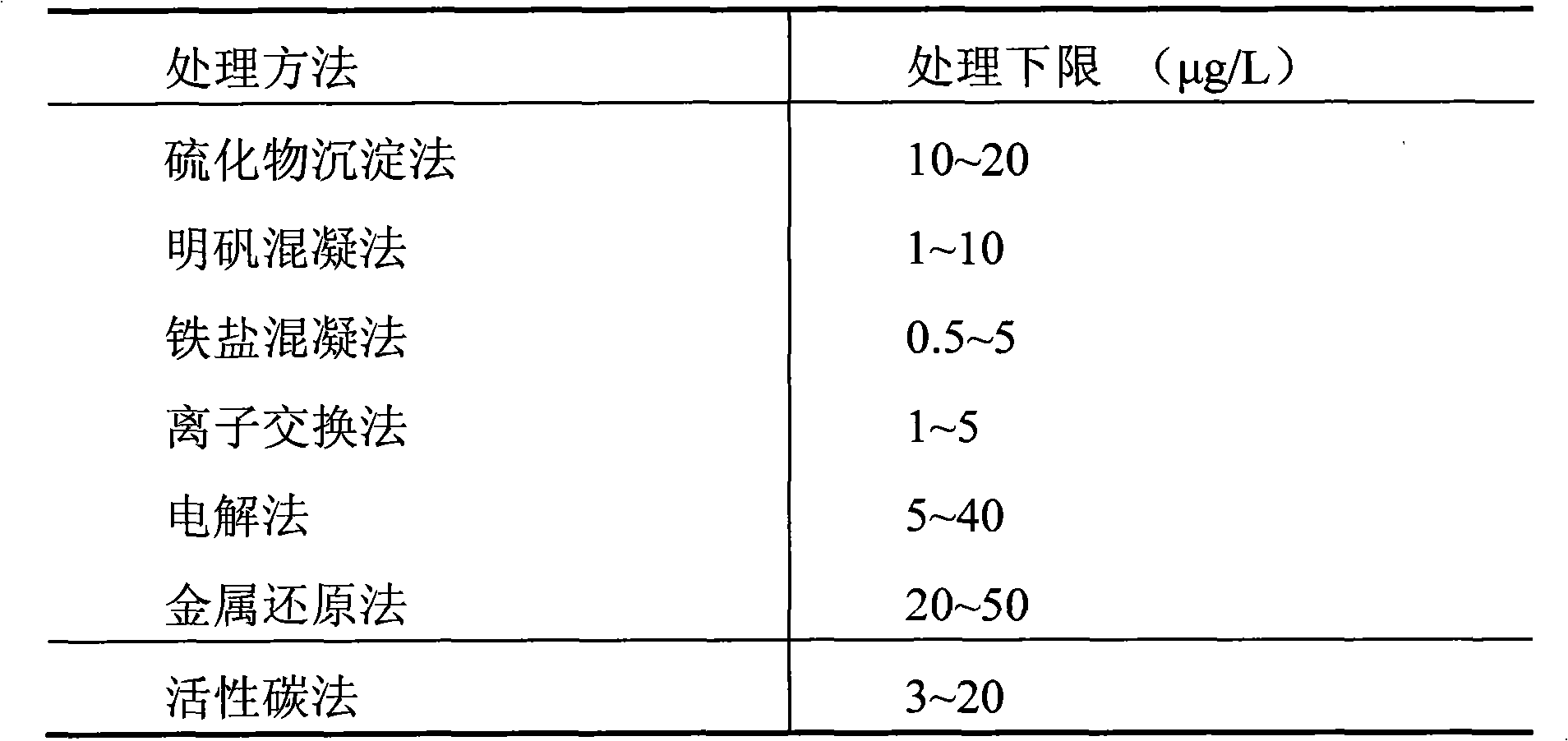

A polymer material and graft modification technology, applied in the field of graft modified polymer material and its preparation, can solve the problems that the treatment method cannot meet the drinking water standard and fishery water standard, and the removal lower limit concentration is high, and achieves rapid adsorption. , high selectivity, economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

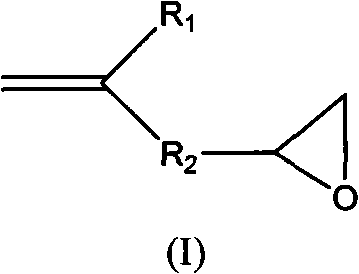

Embodiment 1

[0038] 5g polyethylene non-woven fabric (average pore size is 2.3 microns) is irradiated to 30kGy by gamma rays produced by a cobalt source in an air atmosphere, and 20wt% glycidyl methacrylate and 2wt% Tween 20 are formulated into an emulsion in water , the irradiated thickness is 50 microns, and the polyethylene non-woven fabric with a size of 5 × 5 cm is immersed in 200 ml of emulsion, and under nitrogen protection conditions, the temperature is raised to 60 ° C for 4 hours to obtain a graft rate of 90%. Modified non-woven PE-g-PGMA. The modified non-woven fabric PE-g-PGMA of gained is immersed in the DNA single strand 5 ' (NH of 0.005mmol / L of 200ml 2 )-TTCTTTCTTCCCCTTTGTTTGTT-3' in the water and ethanol mixed solution (the volume ratio of water and ethanol is 3 / 1), add 1mol / L sodium hydroxide aqueous solution to adjust the pH value to 7.5, heat up to 70 ° C, and react for 4 hours to obtain 5'(NH 2 )-TTCTTTCTTCCCCTTTGTTTGTT-3' structure of the modified non-woven fabric, ...

Embodiment 2

[0040] Irradiate 10g of polyvinylidene fluoride powder (the average particle size of the powder is about 0.1mm) to 15kGy in an air atmosphere using γ-rays generated by a cobalt source, add 10mL of glycidyl methacrylate, 1mL of Tween 20, and 100mL of water Prepare an emulsion, add 10 g of irradiated PVDF powder into the emulsion, heat to 60° C. for 6 hours under nitrogen atmosphere, and obtain PVDF-g-PGMA powder with a grafting rate of 95%. Prepare 150mmol / L DNA single strand 5'(NH 2 )-CTTTCCTTCA water and dioxane mixed solution (water and dioxane volume ratio is 2: 1), the PVDF-g-PGMA powder of gained is immersed in this mixed solution of 100ml, add 1mol / L hydrogen Sodium oxide aqueous solution adjusted the pH value to 9.0, raised the temperature to 60°C and reacted for 4 hours to obtain DNA containing single-stranded 5'(NH 2 )-CTTTCCTTCA structure polyvinylidene fluoride powder. The DNA single-strand content was calculated to be 8.1wt% by nitrogen content determination.

Embodiment 3

[0042] Immerse 5g of polystyrene porous microspheres (the average pore diameter of micropores is 1.7 μm) in 100ml of 30wt% glycidyl methacrylate methanol solution, seal the reaction vessel after 30min of nitrogen gas to remove oxygen, and put it into the cobalt 60 source chamber The modified porous microsphere PS-g-PGMA with a grafting rate of 55% was obtained by medium irradiation of 30kGy. The resulting modified porous microsphere PS-g-PGMA was immersed in 100ml of 0.001mmol / L DNA single-stranded NH 2 -In the aqueous solution of TTCTTTCCCCTTTGTT, adjust the pH value to 8.0 with 1mol / L NaOH aqueous solution, and react at 50°C for 12 hours to obtain 2 - Modified porous microspheres of TTCTTTCCCCTTTGTT structure. The DNA single strand content was deduced to be 3.6wt% by nitrogen content determination.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com