Method for preparing fresh motherwort preparation

A technology of fresh motherwort and motherwort, applied in the field of preparation of fresh motherwort preparations of traditional Chinese medicine, can solve the problems of heat-sensitive active ingredient damage, lower product yield, increase humidity, etc., to ensure stability and uniformity, and increase total alkaloid content , to avoid the effect of destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

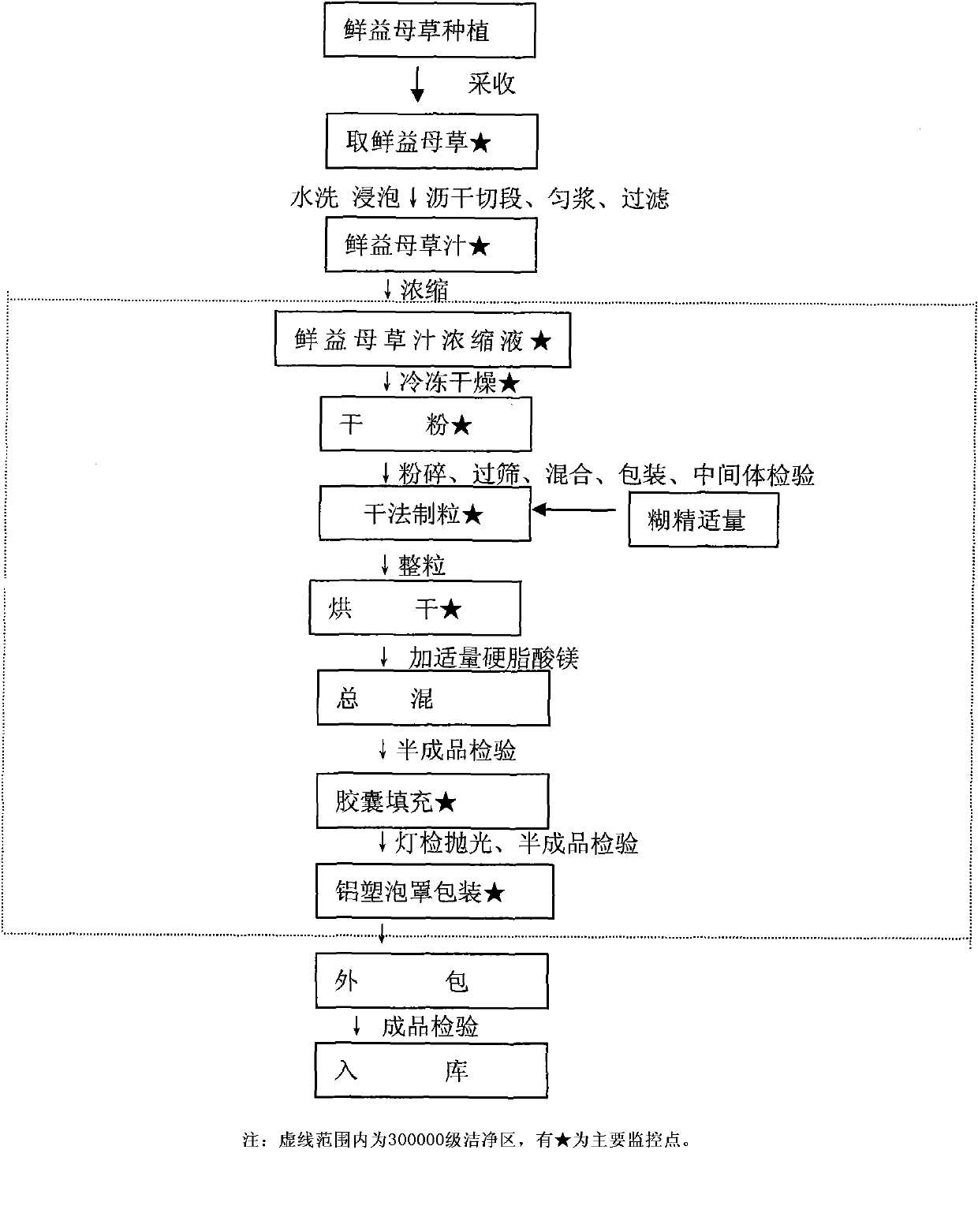

[0026] Embodiment one prepares fresh motherwort capsule

[0027] 1. Planting fresh motherwort

[0028] 1.1 Seed selection: Clean the seeds whose purity does not meet the requirements, use a sieve to remove impurities, remove empty, pests, and other disabled seeds and weed seeds, and select full and plump seeds.

[0029] 1.2 Seed treatment: Turn the seeds in the sun for 1 to 2 days before sowing to make the seeds dry uniformly, increase the permeability of the seeds, and improve the vitality; it also has a certain bactericidal effect. Before sowing, mix 35 kg / mu of plant ash into the seeds, and then mix it with decomposed human excrement and urine to make seed ash, which is good for controlling the sowing amount.

[0030] 1.3 Site selection and site preparation: Select sunny, deep soil, humus-rich soil and well-drained sandy soil, which is slightly acidic and meets the secondary standard in "National Soil Environmental Quality GB15618-1995". more than level three. Remove the...

Embodiment 2

[0059] Embodiment 2 Preparation of fresh motherwort tablets (film-coated tablets) (no auxiliary materials added during freeze-drying)

[0060] The basic process is the same as the preparation of fresh motherwort capsules in Example 1, and steps 1 to 6 are the same as above;

[0061] 7. Dry granulation: take fresh motherwort freeze-dried powder, add 1 / 2 prescription amount of microcrystalline cellulose, mix, place in a dry granulator and granulate with a 30-mesh screen, dry granulation parameters: humidity 40% RH~50%RH, host pressure 6~7MPa, host speed 600r / min, feeding voltage 120V, the prepared granules are sieved with a 20-mesh screen to remove coarse particles, and the sieved coarse particles can be re-granulated.

[0062] 8. Drying: Dry the above granules in an oven, control parameters: temperature 75-85°C, time 5 hours.

[0063] 9. Total blending: Add the remaining microcrystalline cellulose, sodium carboxymethyl cellulose and appropriate amount of magnesium stearate (0....

Embodiment 3

[0068] Embodiment three, preparation fresh motherwort sheet (dispersible tablet) (do not add auxiliary material when freeze-drying)

[0069] The basic process is the same as the preparation of fresh motherwort capsules in Example 1, and steps 1 to 6 are the same as above;

[0070] 7. Dry granulation: take fresh motherwort freeze-dried powder, add 1 / 2 prescription amount of microcrystalline cellulose and low-substituted hydroxypropyl cellulose to mix, put it in a dry granulator and use a 30-mesh screen to granulate, dry-process Granule parameters: Humidity 40%RH~50%RH, main engine pressure 6~7MPa, main engine speed 600r / min, feeding voltage 120V, the prepared granules are sieved with 20 mesh to remove coarse particles, and the sieved coarse particles can be processed Granulate again.

[0071] 8. Drying: Dry the above granules in an oven, control parameters: temperature 75-85°C, time 5 hours.

[0072] 9. Total blending: add the remaining microcrystalline cellulose, cross-linke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com