Method for preparing graphene composite material adsorbing polycyclic aromatic hydrocarbon pollutants

A polycyclic aromatic hydrocarbon and composite material technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of unsatisfactory adsorption efficiency and high cost of carbon nanotubes, and achieve low preparation cost, easy availability of raw materials, and wide application range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

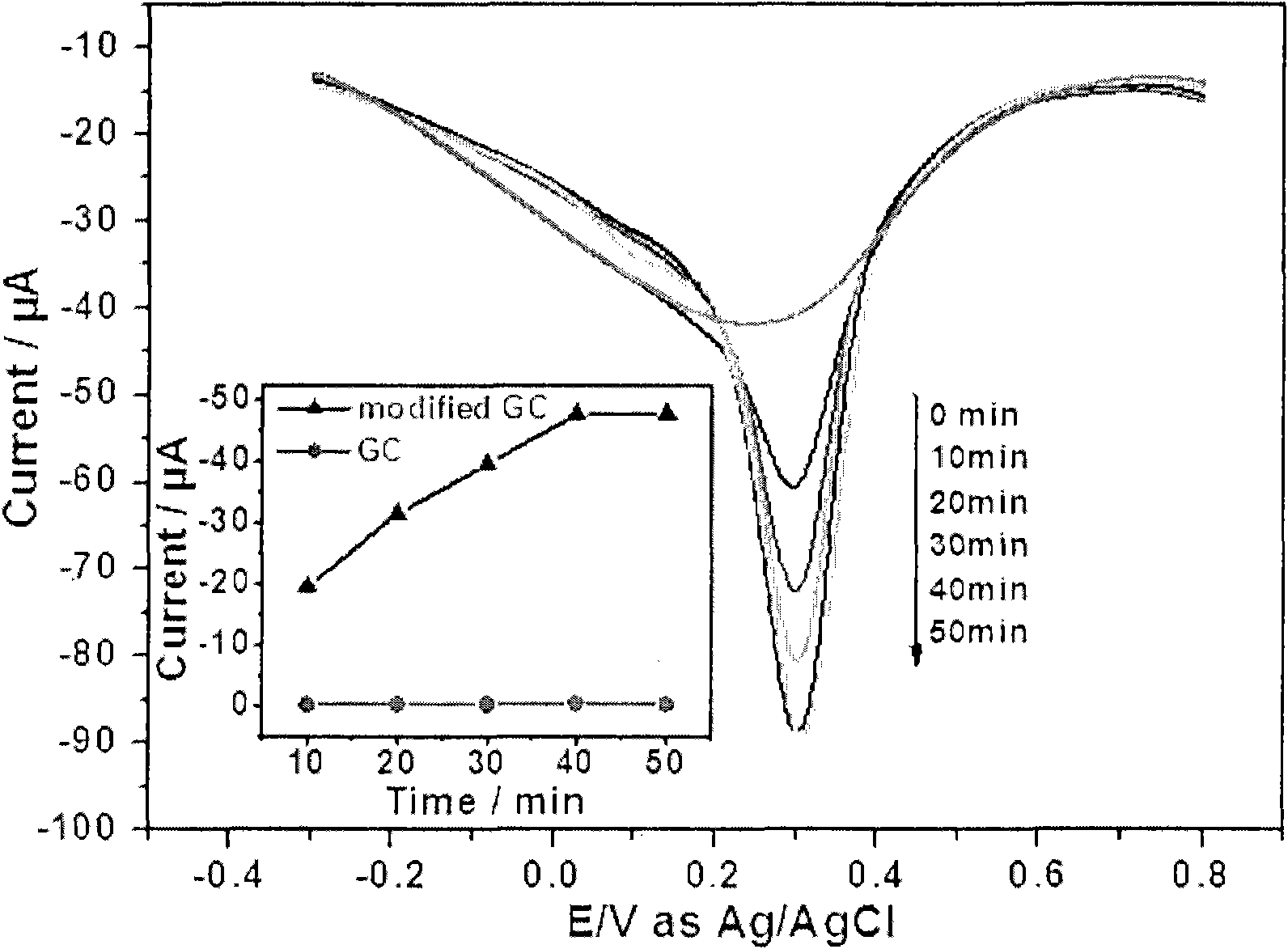

Image

Examples

Embodiment 1

[0029] A certain amount of graphite oxide was weighed and placed in ultrapure water, and ultrasonicated for 30 minutes to obtain a 0.05 wt% graphene oxide suspension. Aspirate 5 mL of it and add 5 mL of ultrapure water, and then add 3.5 μL of hydrazine hydrate (50 wt%) and 35 μL of ammonia water (28 wt%) respectively. After fully mixing, add a layer of silicone oil on the liquid surface to prevent aggregation caused by evaporation of water during heating, and bathe in 95°C water bath for 1 hour to obtain a graphene dispersion solution with a mass content of 0.025%. Under vigorous stirring, add 10 mL of 0.1 mol / L sodium lauryl sulfate and 10 mL of 0.2 mol / L calcium chloride solution, and continue stirring to make the solution uniform. Quickly add 30 mL of 0.2 mol / L sodium carbonate solution to form a precipitate. The precipitate was collected by centrifugation, washed three times with deionized water and absolute ethanol, and dried to obtain a calcium carbonate-supported graph...

Embodiment 2

[0031] Add 0.05 g of graphene to 5 mL of 5% sodium dodecylbenzenesulfonate solution, and ultrasonicate for 10 minutes to obtain a graphene dispersion with a mass content of 1%, which is ready for use. Stir the mixed solution of tetraethyl orthosilicate, absolute ethanol and deionized water for 1 hour, slowly drop into the prepared graphene dispersion solution, and continue to stir for 2 to 3 hours, so that the graphene and the sol solution are fully mixed, and the solution has no precipitation, and then Put the homogeneous composite sol in a 100mL petri dish, seal it with adhesive tape, age and dry to obtain a composite xerogel. During the drying process of the composite gel, the matrix SiO 2A porous structure is formed in which graphene is uniformly dispersed. Then sintering is carried out at 200-1000° C. to remove polymer residues, and a graphene composite material supported by mesoporous silica is obtained after cooling.

Embodiment 3

[0033] A certain amount of styrene was placed in a separatory funnel, and washed four times with 0.1 mol / L NaOH solution and deionized water successively to remove the polymerization inhibitor therein. Add 250mL of water and washed styrene into a five-necked flask, blow in nitrogen, stir and reflux, and heat to 70°C. Add 0.2-1g graphene, stir and disperse for 30min. Initiator K 2 S 2 o 8 Dissolve in 50mL of distilled water, heat to 70°C, add dropwise into a five-necked bottle, finish dropping in 30min, and react for 15h to obtain a brown-black graphene-dispersed polystyrene emulsion. The emulsion can be coated on a carrier such as glass, and dried to obtain a composite material of polycyclic aromatic hydrocarbons supported by polystyrene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com