Health-care food with functions of improving skin moisture and reinforcing immunity

A technology to improve skin moisture and enhance immunity, applied in food preparation, food science, application and other directions, can solve problems such as malignant tumors and persistent infections, achieve strong market competitiveness, enhance immunity, have no toxic side effects and Effects of adverse reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

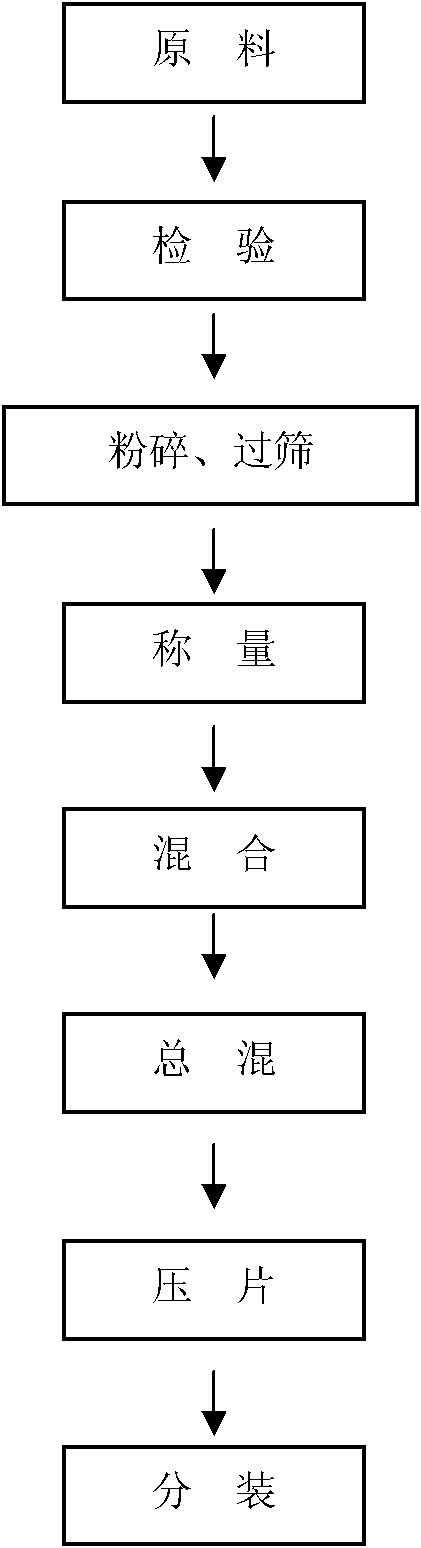

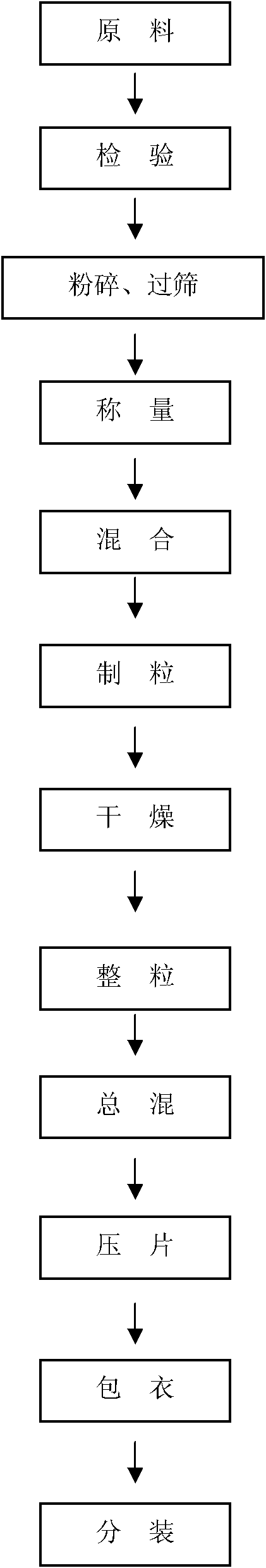

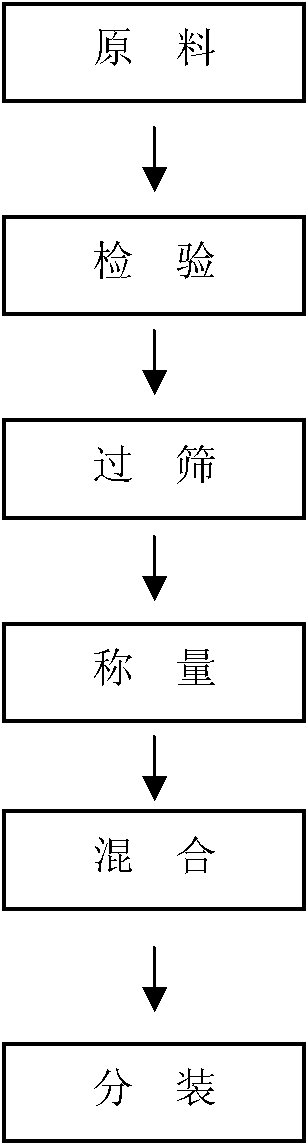

Image

Examples

Embodiment 1

[0035] Embodiment one: the preparation of collagen peptide powder

[0036] Fish scales are used as raw materials, decalcified, washed, dried, extracted, extracted with pure water at 95-100°C for 2-6 hours, filtered through a mesh sieve, and the extract is separated from the remaining fish scales to obtain collagen Extract solution, add papain to the collagen extract solution for enzymolysis, add activated carbon to decolorize the enzymolysis solution after enzymolysis, filter to remove activated carbon and other impurities, remove heavy metal plasma through resin, and achieve the purpose of refining. The vacuum concentration process concentrates the enzymolysis solution, undergoes high temperature instantaneous sterilization at 110°C for 20-30 seconds, and finally sprays and dries to obtain the collagen peptide powder.

Embodiment 2

[0037] Embodiment two: the preparation of collagen peptide powder

[0038] The fish skin raw material taken out from the cold storage is thawed in the natural environment for 10-24 hours, and then moistened with warm water at about 40°C to make it soft and easy to process. Use a crusher to crush the moistened fish skin, and add pure water at about 50°C to make a paste. Transfer the slurry to an enzymatic hydrolysis tank, constant volume, heat and add ethanol to remove impurities. After removing impurities, adjust the volume again, adjust the pH to 7.0-8.5, add chymotrypsin and papain, and enzymatically hydrolyze at 40-55°C for 3.5 hours, stirring continuously during the process. Inactivate the enzyme after the reaction is complete. The enzymolysis solution is subjected to centrifugation to remove residues, the clear solution is filtered through a membrane, concentrated at low temperature, decolorized with activated carbon, sterilized, and spray-dried to obtain the collagen p...

Embodiment 3

[0039] Embodiment three: the preparation of glucosamine

[0040] Glucosamine can be made in the form of various salts. For example, glucosamine hydrochloride is made by the following method: Shrimp and crab shells are treated with about 8% hydrochloric acid for 24 hours until the ash content is ≤10%, and they are washed until the pH value is above 6. . The above-mentioned cleaned shrimp and crab shells were treated with 5% sodium hydroxide solution at 100° C. for 3 hours and then washed to a pH value below 8. The above-mentioned cleaned product is dried at a temperature of 90°C-100°C until the water content is less than or equal to 15%, which is the finished product of chitin. Chitin was hydrolyzed with ≥31% hydrochloric acid solution for 5 hours at 90°C. Precipitate the above hydrolyzate at room temperature, and obtain crude glucosamine hydrochloride after filtration. The crude glucosamine hydrochloride was redissolved and decolorized with activated charcoal. The glucosam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com