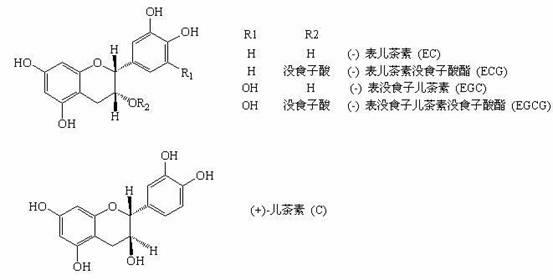

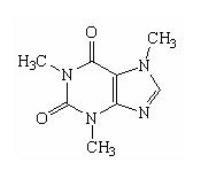

Methods for preparing high-hydrophilcity macroporous absorption resin and removing caffeine in crude tea extracts

A pore adsorption and caffeine technology, which is applied in the field of high-purity tea polyphenol extracts, can solve the problems of inability to achieve complete separation of tea polyphenols and caffeine, the separation process cannot be completed at normal pressure, and the operation is complicated, so as to ensure recovery. , suitable for large-scale industrial production, the effect of simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Preparation of Highly Hydrophilic Alcohol Hydroxyl Macroporous Adsorption Resin

[0023] Add 425mL of 0.5% gelatin aqueous solution into a 1000mL three-necked bottle at room temperature, and heat to 40°C. Mix 28g TAIC, 56g VAc, 84g n-heptane, and 0.84g AIBN evenly, pour it into a three-necked flask, start stirring and slowly raise the temperature to 60°C at a heating rate of 0.5°C / min, react for 5 hours, and then raise the temperature to 80°C , reacted for 6 hours, stopped stirring and heating, let it stand to room temperature, filtered out the resin, washed it with a large amount of deionized water, and dried it in vacuum.

[0024] Add 60g of the above-mentioned dry resin into a 500mL three-necked flask, add 250g of sodium hydroxide aqueous solution with a mass percentage concentration of 5%, start stirring, raise the temperature to 50°C, and react for 5 hours, stop stirring and heating, and let it stand at room temperature. Filter out, wash with a large ...

Embodiment 2

[0025] Example 2 : Preparation of Highly Hydrophilic Alcoholic Hydroxyl Macroporous Adsorbent Resin

[0026] Add 900mL of 1% gelatin aqueous solution into a 2000mL three-necked bottle at room temperature, and heat to 45°C. Mix 40g TAIC, 160g VAc, 100g n-octane, and 1.5g AIBN evenly, pour it into a three-necked flask, start stirring and slowly raise the temperature to 70°C at a heating rate of 0.2°C / min, react for 8 hours, and then raise the temperature to 90°C , reacted for 4 hours, stopped stirring and heating, let stand to room temperature, filtered out the resin, washed with a large amount of deionized water, and dried in vacuum.

[0027] Add 150g of the above-mentioned dried resin into a 1000mL three-necked flask, add 750g of sodium hydroxide aqueous solution with a mass percentage concentration of 10%, start stirring, raise the temperature to 60°C, and react for 2 hours, stop stirring and heating, and let it stand at room temperature. Filter out, wash with a large am...

Embodiment 3

[0028] Example 3: Preparation of Highly Hydrophilic Alcohol Hydroxyl Macroporous Adsorption Resin

[0029] Add 1200mL of 0.5% gelatin aqueous solution into a 3000mL three-necked bottle at room temperature, and heat to 50°C. Mix 80g TAIC, 80g VAc, 240g dodecane, and 1.0g AIBN evenly, pour it into a three-necked bottle, start stirring and slowly raise the temperature to 62°C at a heating rate of 0.4°C / min, react for 6 hours, and then raise the temperature to 87°C , reacted for 4 hours, stopped stirring and heating, let stand to room temperature, filtered out the resin, washed with a large amount of deionized water, and dried in vacuum.

[0030] Add 120g of the above-mentioned dried resin into a 1000mL three-necked flask, add 540g of sodium hydroxide aqueous solution with a concentration of 7% by mass, start stirring, raise the temperature to 55°C, and react for 4 hours, stop stirring and heating, and let it stand at room temperature. Filter out, wash with a large amount of de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com