Dye mesoporous adsorbent taking rice hulls as templates and silicon sources and preparation method thereof

A technology of adsorbent and template, which is applied in the direction of chemical instruments and methods, adsorption water/sewage treatment, silicon compounds, etc., can solve the problems of material application that have not been explored in depth, and achieve improved adsorption performance and spatial structure, low production cost, The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

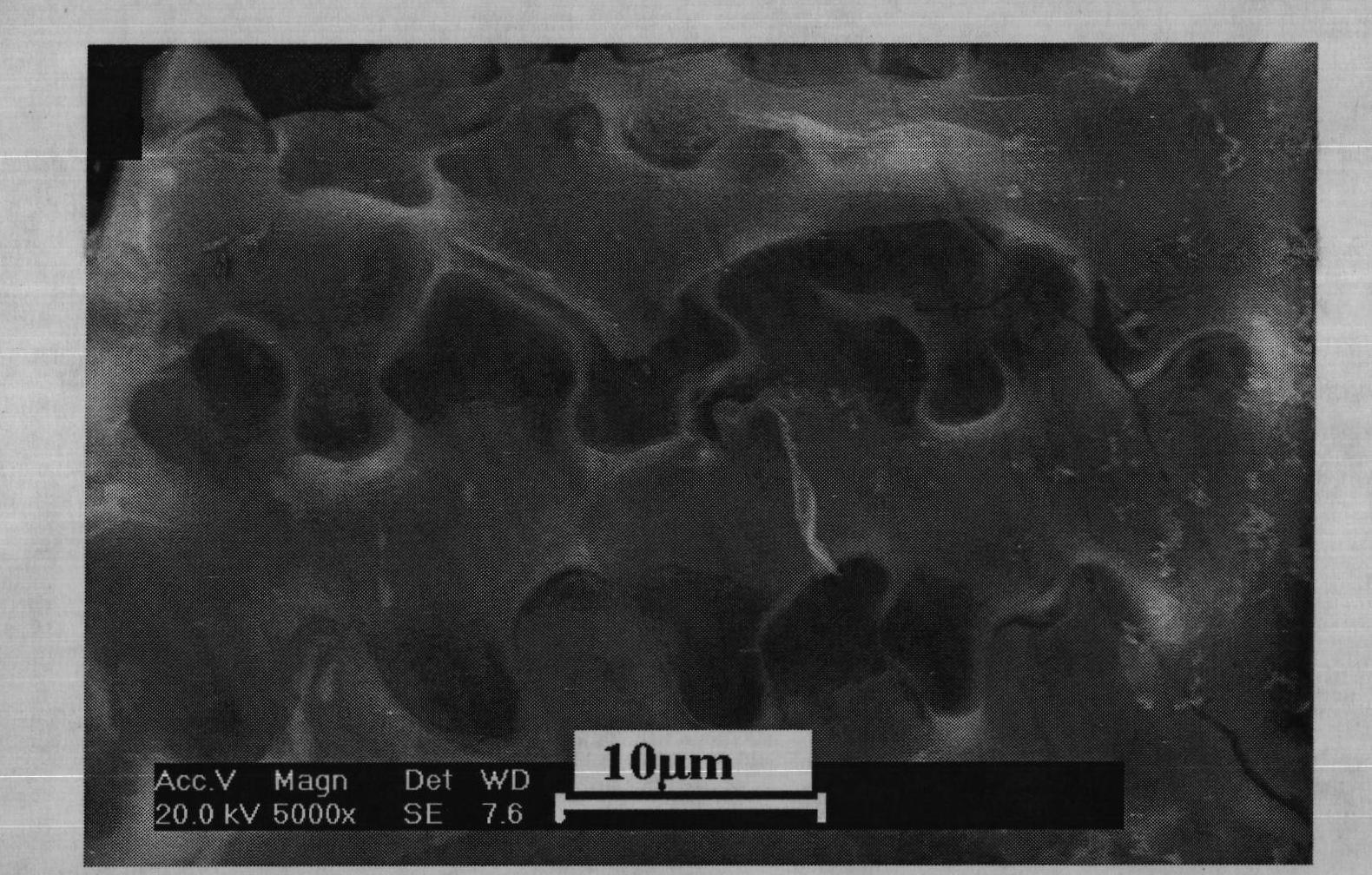

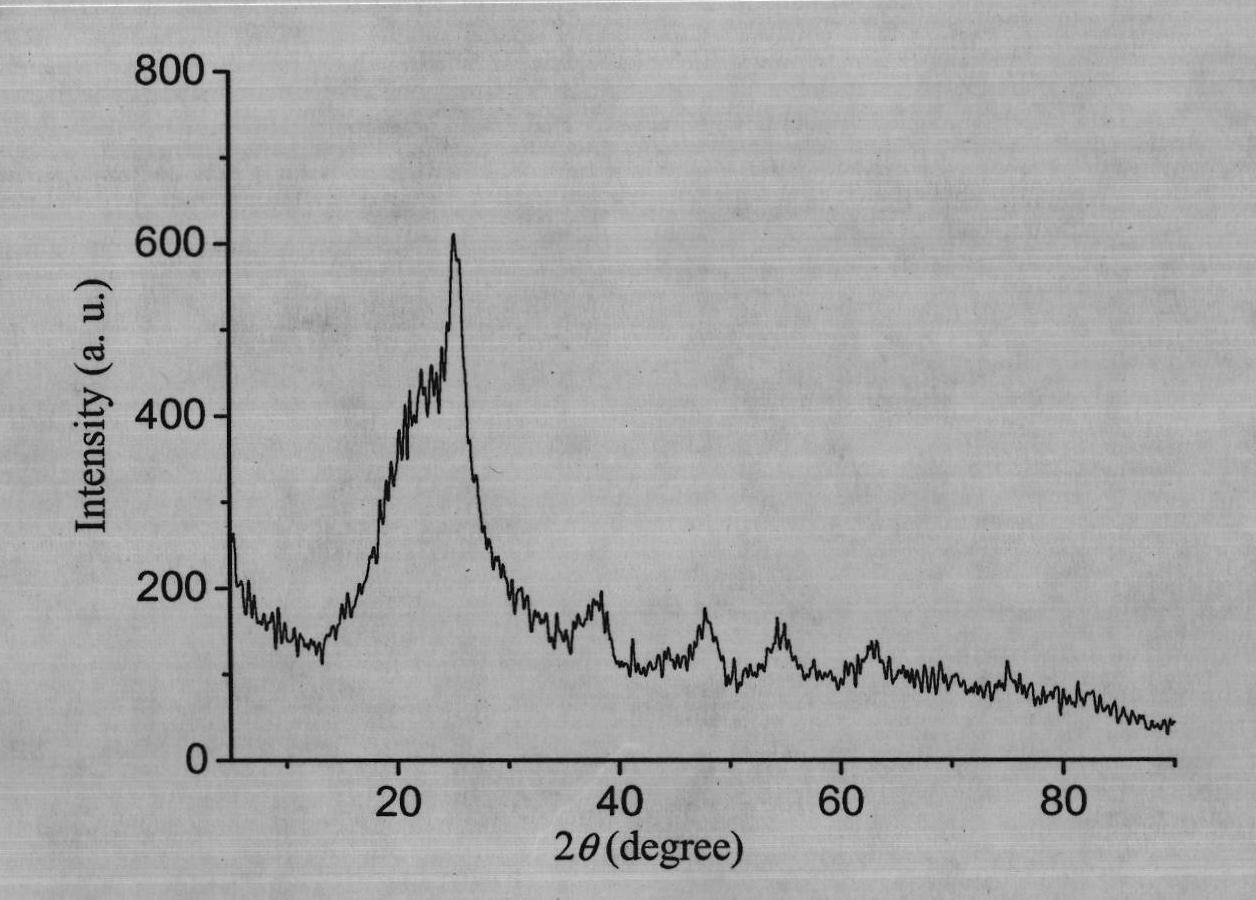

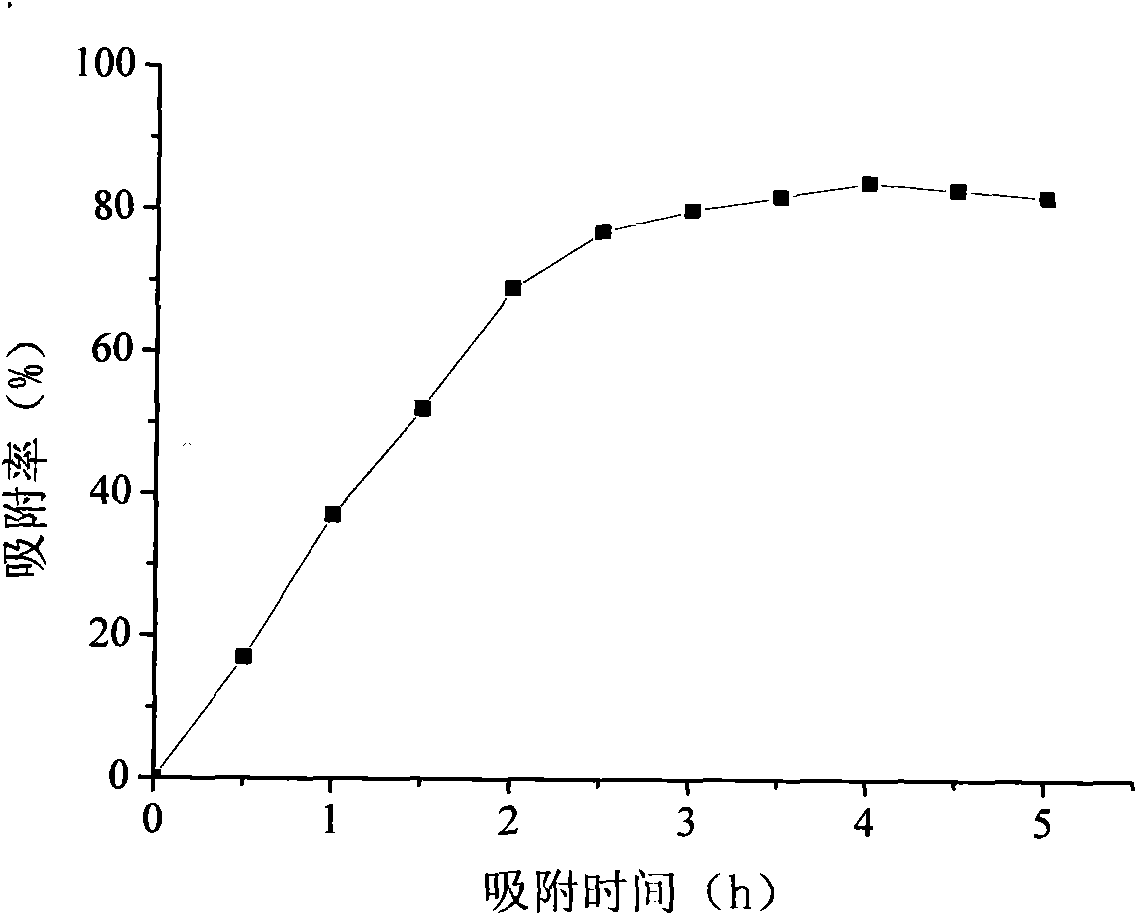

Embodiment 1

[0035] Soak rice husks in 1mol / L hydrochloric acid solution, reflux at 40°C for 24 hours, wash, and dry naturally. Then soak the rice husk in 1mol / L sodium hydroxide solution, reflux at 40°C for 24 hours, wash and dry. After soaking in the precursor solution for reaction, ultrasonic vibration for 6 minutes, standing for 2 hours, then adding transition metal solution, ultrasonic vibration for 10 minutes, standing for 4 hours. The treated rice husk was soaked in distilled water for 2 hours of hydrolysis reaction, taken out and dried at 60°C, and finally heated from room temperature at a rate of 5°C / min at 450°C, and calcined for 5 hours to obtain the product. The precursor solution is a solution in which the precursor is the solute and the diluent is the solvent, and the concentration of the precursor solution is 0.1% of the volume of the solution. The precursor is titanium tetraisopropoxide. Said diluent is ethanol. Said transition metal solution is an aqueous solution with ...

Embodiment 2

[0037] The rice husks were soaked in 2mol / L hydrochloric acid solution, refluxed at 80°C for 10 hours, washed, and dried at 60°C. Then soak the rice husk in 4mol / L sodium hydroxide solution, heat and reflux for 24 hours, wash and dry naturally. After soaking in the precursor liquid for reaction, ultrasonic vibration for 20 minutes, standing still for 24 hours, then adding the transition metal solution, ultrasonic vibration again for 30 minutes, standing still for 20 hours. The treated rice husk is soaked in an ammonia-ammonium chloride buffer solution for hydrolysis reaction for 10 hours, taken out for natural drying, and finally heated at a rate of 8°C / min from room temperature at 400°C and calcined for 20 hours. The precursor solution is a solution in which the precursor is the solute and the diluent is the solvent. The concentration of the precursor solution is that the precursor accounts for 8% of the volume of the solution. The precursor is titanium tetraisopropoxide. S...

Embodiment 3

[0039] The rice husks were soaked in 4mol / L hydrochloric acid solution, refluxed at 50°C for 24 hours, washed and dried. Then soak the rice husk in 6mol / L sodium hydroxide solution, reflux at 40°C for 36 hours, wash and dry. After soaking in the precursor solution for reaction, ultrasonic vibration for 5 minutes, standing for 2 hours, then adding transition metal solution, ultrasonic vibration for 10 minutes, standing for 4 hours. Soak the treated rice husk in the hydrolyzate sodium bicarbonate-sodium dihydrogen carbonate buffer solution for hydrolysis reaction for 2 hours, take it out and dry it at 60°C, and finally raise the temperature from room temperature at a heating rate of 7°C / min under the condition of 700°C , Calcined for 2h to obtain the product. The precursor solution is a solution in which the precursor is the solute and the diluent is the solvent. The concentration of the precursor solution is that the precursor accounts for 8% of the volume of the solution. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com