Biomedical material having porous calcium phosphate-collagen composite coating and preparation method of biomedical material

A biomedical material, porous calcium phosphate technology, applied in coatings, medical science, prostheses, etc., can solve problems such as brittle fracture or peeling, unusable bearing parts, insufficient mechanical properties, etc., to promote cell adhesion, Reducing the dosage and maintaining the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

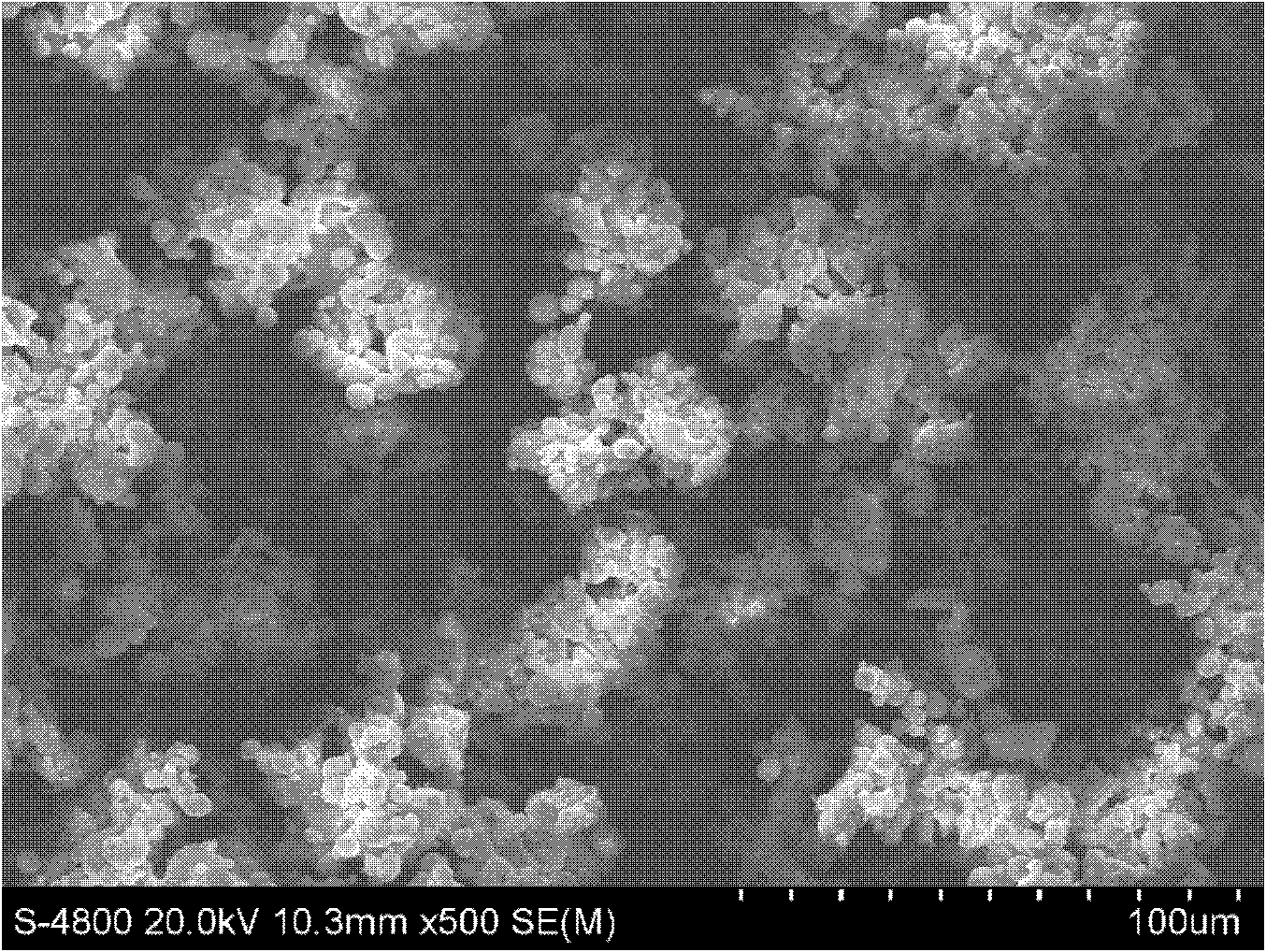

[0055] The invention provides a method for preparing a biomedical material with a porous calcium phosphate-collagen composite coating. The method is based on plasma spraying to prepare a porous calcium phosphate coating, and directly compound a collagen surface layer on the surface of the porous coating. .

[0056] The specific operation steps are:

[0057] A preparation of porous calcium phosphate coating

[0058] According to the calcium-phosphorus molar ratio of hydroxyapatite, tricalcium phosphate, etc., add the diammonium hydrogen phosphate aqueous solution with a molar concentration of 1.2-3.6 mol / L dropwise to calcium nitrate with a molar concentration of 1-3 mol / L under constant stirring In the aqueous solution, keep the reaction liquid at 30-90°C, control its pH at 9-12 with ammonia water with a concentration of 10%-30% by mass percentage, let it stand for 5-15 minutes after the reaction, and then age for 24-48 hours, add commonly used pore forming agent (such as de...

Embodiment 1

[0065] Embodiment 1 The preparation of the biomedical material with porous calcium phosphate-collagen composite coating of the present invention

[0066] Press Ca 10 (PO 4 )6 (OH) 2 The molar ratio of calcium to phosphorus (1.67), under constant stirring, the 2.8mol / L diammonium hydrogen phosphate aqueous solution is added dropwise in the 2.4mol / L calcium nitrate aqueous solution, and the reaction solution is kept at 70°C, and the concentration is 25% by mass percentage. Ammonia water was used to keep the pH at 10.5. After the reaction, it was allowed to stand for 10 minutes, and then aged for 24 hours to obtain a hydroxyapatite suspension with a solid content of 34%. Then add the pore-forming agent deionized water to the hydroxyapatite suspension, and dilute it into a hydroxyapatite suspension with a solid content of 17% for later use. Using plasma spraying equipment, the nozzle adopts atomizing nozzle, and the liquid plasma spraying method is used, on the biomedical titan...

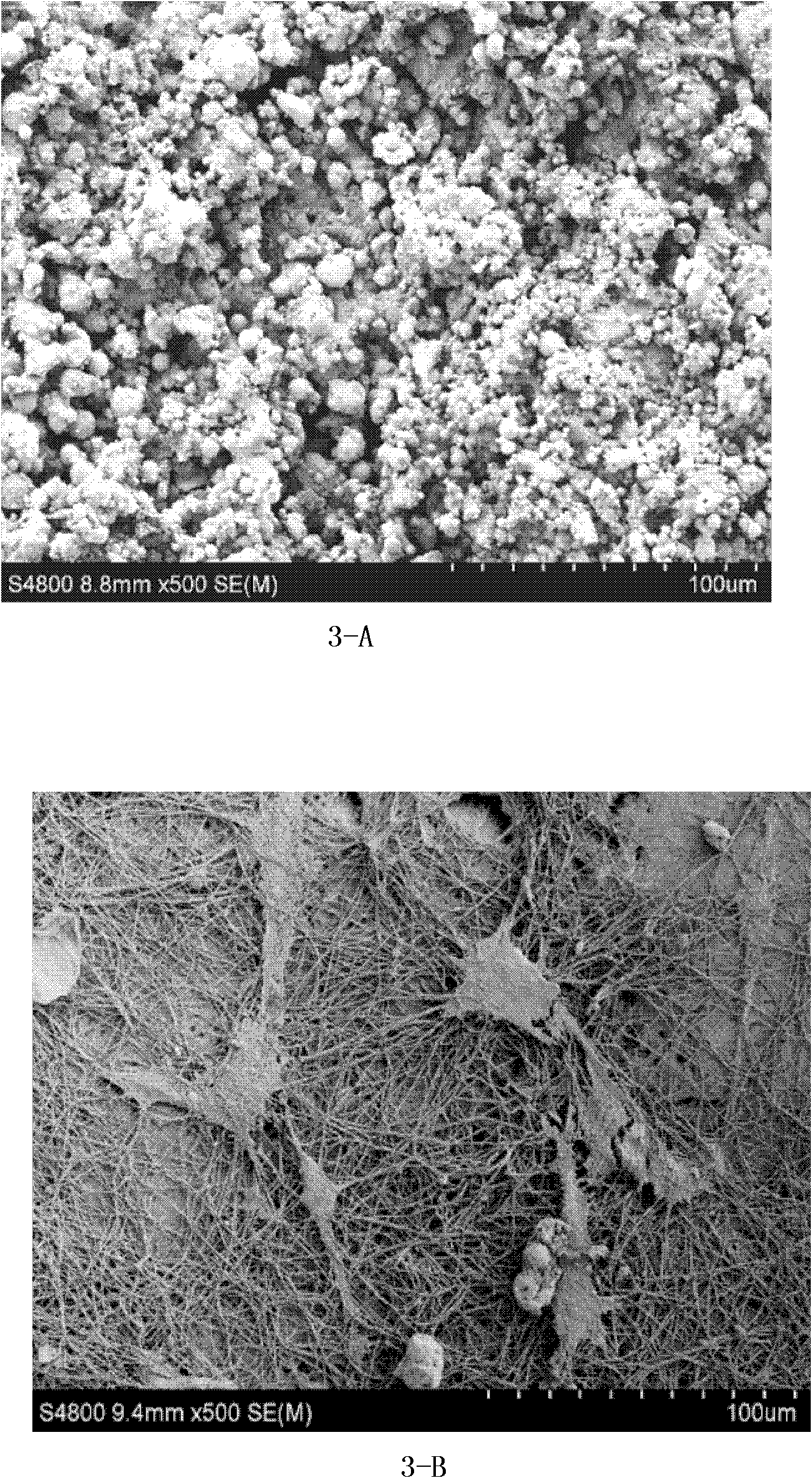

Embodiment 2

[0067] Example 2 Preparation of Biomedical Materials with Porous Calcium Phosphate-Collagen Composite Coating in the Present Invention

[0068] Press Ca 10 (PO 4 ) 6 (OH) 2 The molar ratio of calcium to phosphorus (1.67), under constant stirring, the diammonium hydrogen phosphate aqueous solution with a molar concentration of 2.8mol / L is added dropwise to the calcium nitrate aqueous solution with a molar concentration of 2.4mol / L, and the reaction solution is kept at 70°C. Ammonia water with a mass percentage concentration of 25% was used to control the pH at 10.5, and after the reaction, it was allowed to stand for 10 minutes, and then aged for 24 hours to obtain a hydroxyapatite suspension with a solid content of 34%. The pore-forming agent deionized water was added to the hydroxyapatite suspension, and it was diluted to form a hydroxyapatite suspension with a solid content of 17% for later use. Utilize the plasma spraying equipment, the nozzle adopts the atomizing nozzl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com