Composite lithium manganese phosphate serving as lithium ion battery anode material and preparation method thereof and lithium ion battery

A technology for composite lithium manganese phosphate and lithium-ion batteries, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of difficult commercial application, poor safety, high price, etc., and achieve the improvement of electrochemical discharge capacity and rate Discharge performance, excellent electrical conductivity, and the effect of improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

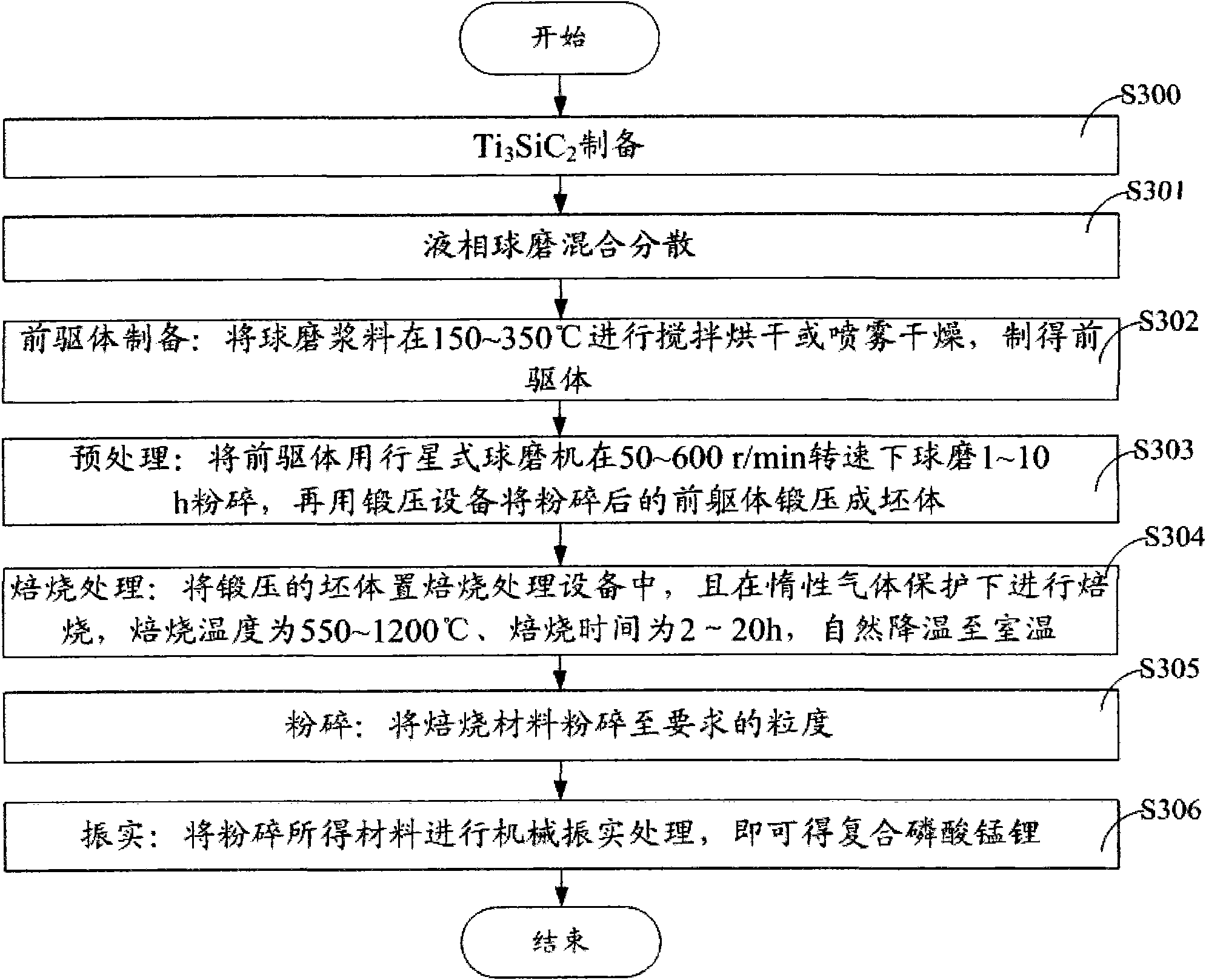

[0026] Please see figure 1 , which is a preparation method of composite lithium manganese phosphate in a preferred embodiment, using the preparation method of composite lithium manganese phosphate to produce composite lithium manganese phosphate to be used as the positive electrode material of lithium ion battery, the preparation method of the composite lithium manganese phosphate includes Follow the steps below:

[0027] Step S300, Ti 3 SiC 2 Preparation: Mix Ti, Si and C powders according to the ratio of 3:1:2, and use ethanol, or pure water, or a mixture of ethanol and pure water as a dispersant in a ball mill for 2-20 hours, After the slurry is stirred and dried or spray-dried, it is forged and pressed to form a green body, which is roasted under the protection of an inert gas at a roasting temperature of 1000-1500 °C and a roasting time of 1-20 hours, naturally cooled to room temperature, and then crushed to particle size Standby for nanoscale or submicron scale. Amon...

Embodiment 1

[0036] Ti 3 SiC 2 Preparation: Mix Ti, Si and C powders according to the material ratio of 3:1:2, ball mill in the QM planetary ball mill of Nanjing University at a speed of 450r / min, and ethanol as the dispersion medium for 18h, and the slurry is granulated by LDZ pressure spray Drying machine spray drying, the dried material is forged into a green body by a flat vulcanizing machine, roasted at 1200°C for 10 hours under the protection of argon, naturally cooled to room temperature, and then crushed to nano or submicron by a jet mill for use. The prepared material is suitable for all examples.

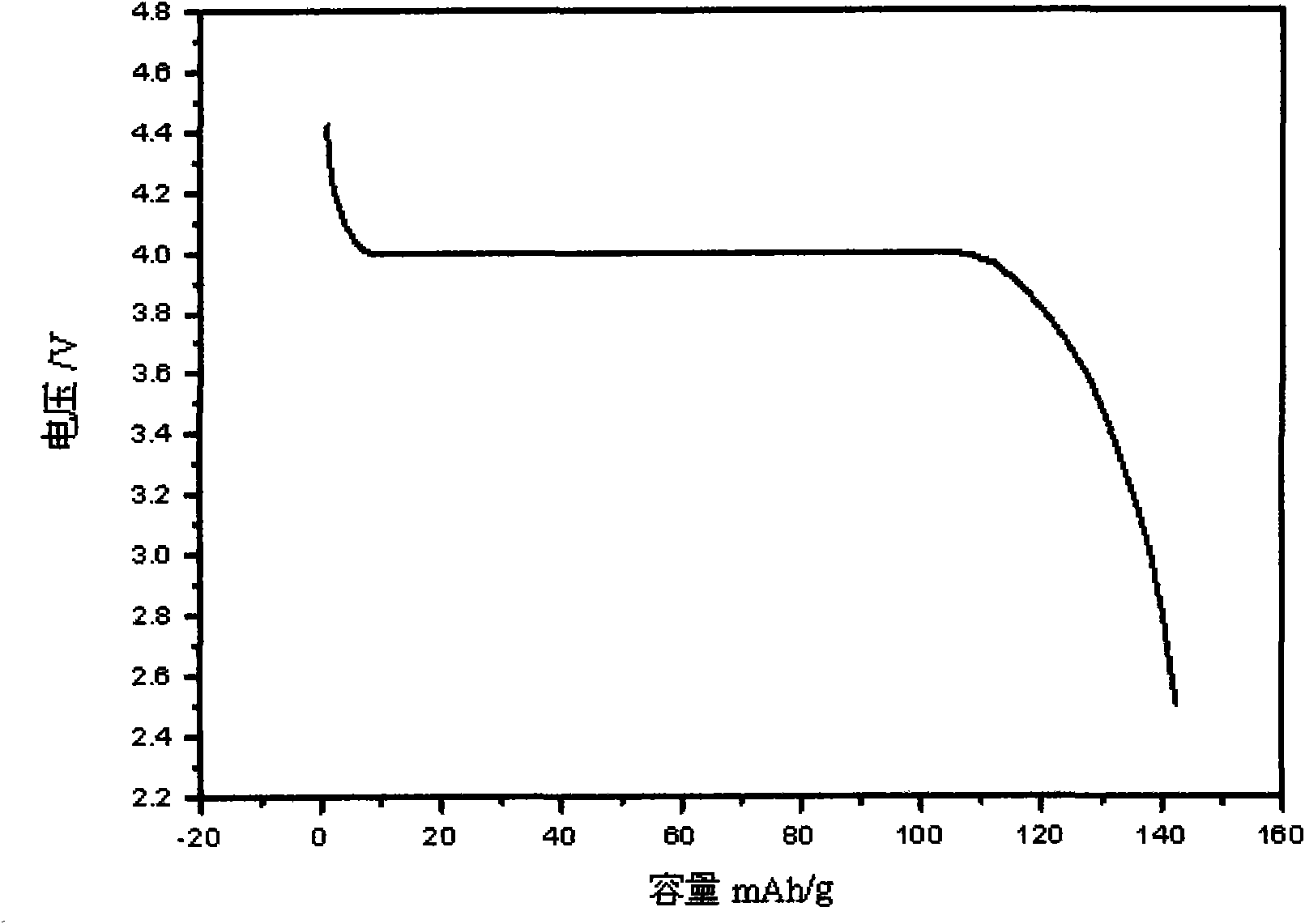

[0037] Accurately weigh 155.91 grams of lithium dihydrogen phosphate, 367.64 grams of manganese acetate, 3.5 grams of magnesium acetate, 10.3 grams of iron oxide, 0.8 grams of niobium pentoxide, 1.1 grams of silver oxide, Ti 3 SiC 2 20 grams, added to 500ml ethanol while stirring, and then using a QM planetary ball mill to use agate balls as the ball milling medium for 24 hours at a...

Embodiment 2

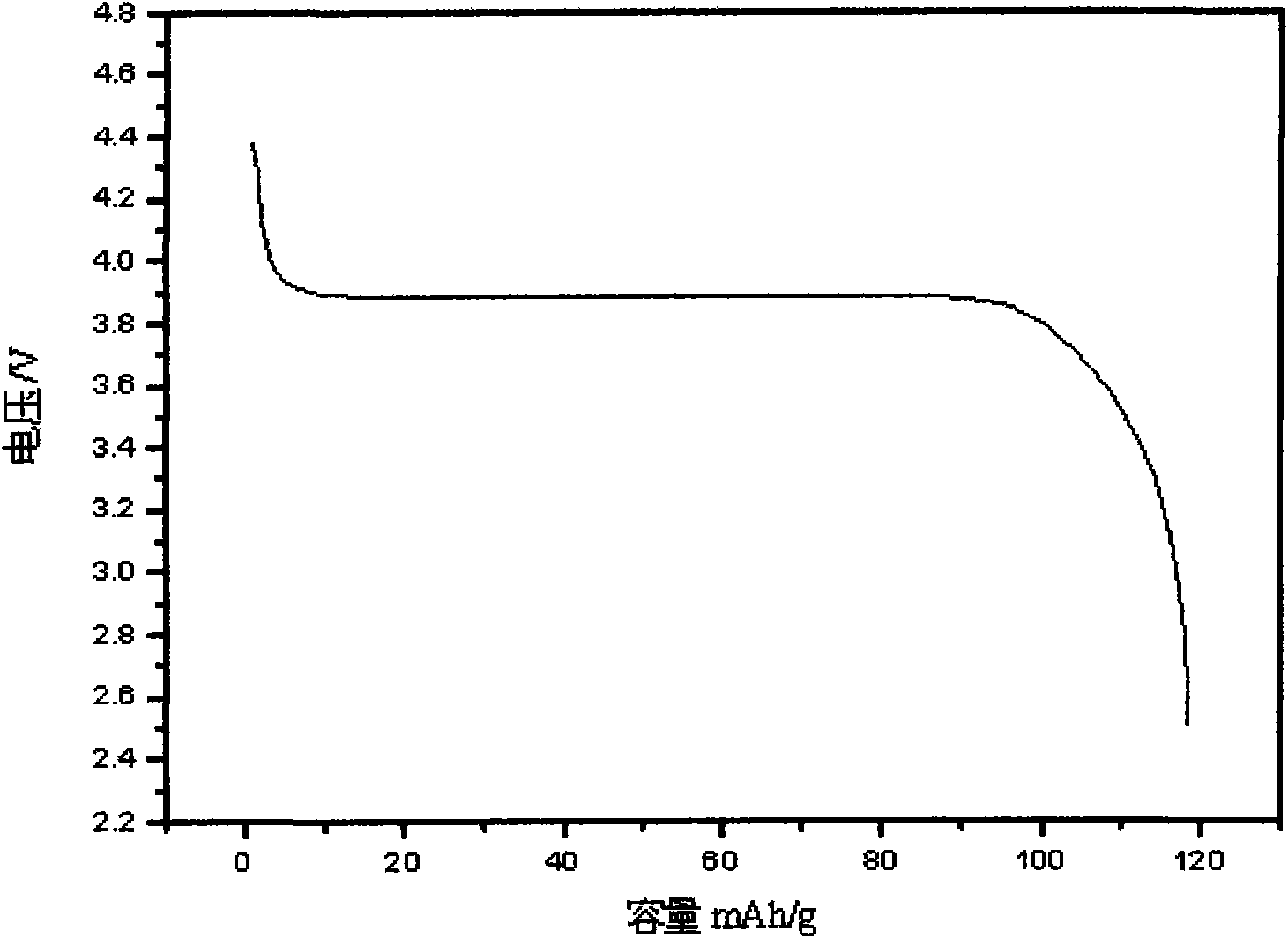

[0040] Accurately weigh 1124.2 grams of lithium acetate, 1149.5 grams of manganese carbonate, 1150.3 grams of ammonium dihydrogen phosphate, 13.3 grams of magnesium oxide, 5.1 grams of aluminum oxide, 13 grams of copper oxide, 5 grams of cerium oxide, Ti 3 SiC 2 33 grams, was added to 10000ml pure water while stirring, and then used QM planetary ball mill to use zirconia balls as the ball milling medium at a speed of 600rpm for 2 hours; the prepared slurry was spray-dried at 350°C to obtain the precursor; The precursor was ball-milled at 50rpm for 10 hours with a roller ball mill, and then pressed into a green body with a flat vulcanizer; the green body was roasted at 550°C in a rotary furnace under the protection of argon for 20 hours, and then naturally cooled to room temperature; 150 ultrafine pulverizer to crush to the required particle size; mechanically vibrate the obtained material with a vibrator to obtain a composite lithium manganese phosphate material.

[0041] Aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com