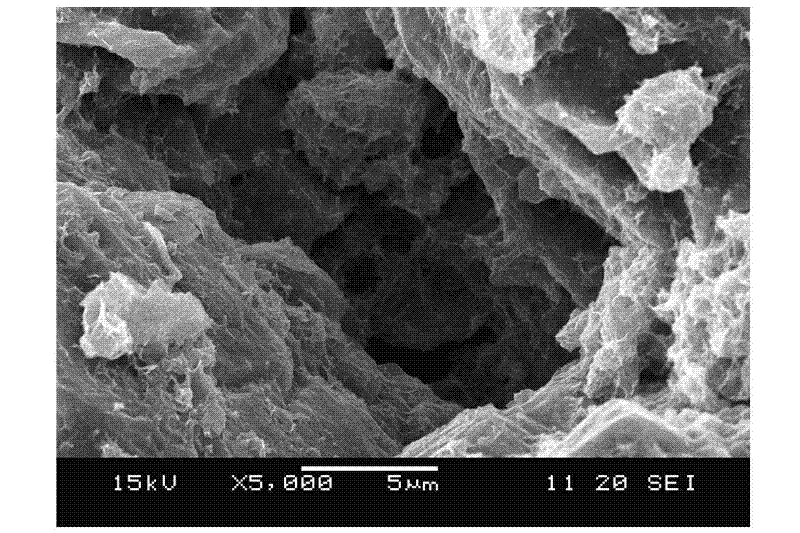

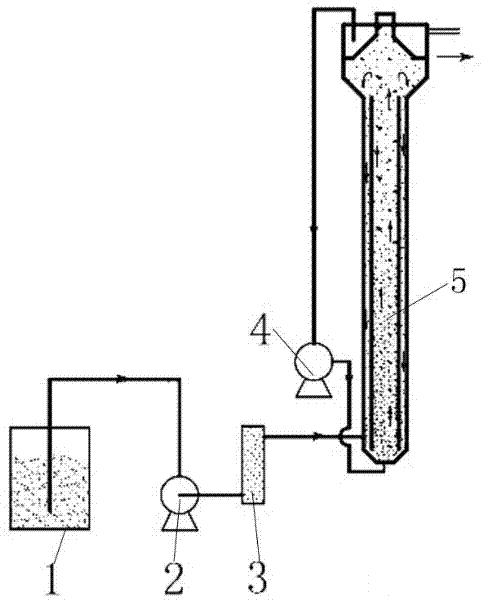

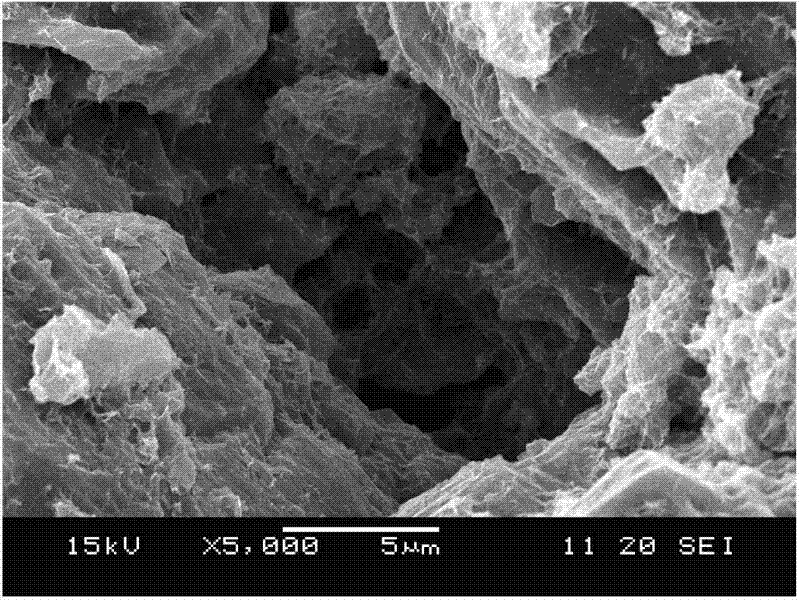

High-density porous support for treating wastewater of biological fluidized bed and preparation method thereof

A biological fluidized bed and porous carrier technology is applied in the fields of sewage treatment, high-density porous carrier and its preparation. Sewage treatment efficiency, beneficial to microbial attachment, and the effect of improving mass transfer speed and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Mix 1Kg of fly ash, 4.8Kg of kaolin, 2Kg of coal gangue and 0.2Kg of nylon evenly, then add 1.7Kg of water and 0.3Kg of polyethylene glycol-400 for secondary stirring, and age for 3 days , the mixture was pressed into tablets, dried at 80°C for 4h, then moved into a muffle furnace for calcination, and calcined at 1000°C for 2h. Grind and pulverize after cooling, and sieve with a 20-40 mesh screen. Then put the carrier into 10mol / L hydrochloric acid to expand the pores, after drying, immerse in 35% concentration of exopolysaccharide aqueous solution for 30 min, and dry in the shade to obtain the high-density porous carrier GM-1, in which the exopolysaccharide Glucose 2.625Kg, rhamnose 1.575Kg, mannose 1.05Kg, water 9.75Kg in polysaccharide aqueous solution.

[0043] The weight percentages of the above added materials are: fly ash 10%, kaolin 48%, coal gangue 20%, nylon 2%, water 17%, polyethylene glycol-400 3%. The mass ratio of glucose, rhamnose and mannose in the pse...

Embodiment 2

[0047] Stir the mixture of 1.2Kg of fly ash, 5Kg of bentonite, 1Kg of coal gangue and 0.2Kg of acrylic fibers evenly, then add 2Kg of water and 0.6Kg of polyvinyl alcohol for secondary stirring, age for 4 days, and press the mixture The flakes were dried at 100°C for 5h, then moved into a muffle furnace for calcination, and calcined at 1050°C for 2h. Grind and pulverize after cooling, and sieve with a 20-40 mesh screen. Then put the carrier into 10mol / L nitric acid to expand the pores, after drying, immerse in a 30% concentration of exopolysaccharide aqueous solution for 30 min, and dry in the shade to obtain the high-density porous carrier GM-1, in which the exopolysaccharide Glucose 1.8Kg, rhamnose 1.8Kg, mannose 0.9Kg, water 10.5Kg in polysaccharide aqueous solution.

[0048] The weight percentages of the above added materials are: fly ash 12%, bentonite 50%, coal gangue 10%, acrylic fiber 2%, water 20%, polyvinyl alcohol 6%. The mass ratio of glucose, rhamnose and mannos...

Embodiment 3

[0052] Stir 1.8Kg of fly ash, 4.7Kg of attapulgite, 0.7Kg of coal gangue and 0.4Kg of polypropylene fiber mixture evenly, then add 1.9Kg of water and 0.5Kg of phosphoric acid for secondary stirring, and age for 5 days. The mixture was pressed into tablets, dried at 90°C for 4.5h, then moved into a muffle furnace for calcination, and calcined at 1000°C for 3h. Grind and pulverize after cooling, and sieve with a 20-40 mesh screen. Then the carrier was put into 10mol / L sodium hydroxide to expand the pores, after drying, it was immersed in 25% concentration of exopolysaccharide aqueous solution for 30 min, and dried in the shade to obtain the high-density porous carrier GM-1. Glucose 1.125Kg, rhamnose 1.5Kg, mannose 1.125Kg, water 11.25Kg in exopolysaccharide aqueous solution.

[0053] The weight percentages of the above added materials are: fly ash 18%, attapulgite 47%, coal gangue 7%, polypropylene fiber 4%, water 19%, polyvinyl alcohol 5%. The mass ratio of glucose, rhamnose ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com