Positive charged composite nanofiltration membrane and preparation method thereof

A composite membrane and compound technology, applied in the field of membrane separation, can solve the problems of low removal rate and only 40% removal rate, and achieve the effects of wide source of raw materials, high retention rate and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention also provides a method for preparing a compound of formula (I), comprising the following steps:

[0038] Isophthalic acid and paraformaldehyde react in sulfuric acid to obtain 3,3',5,5'-tetracarboxydiphenylmethane;

[0039] Add SOCl to the 3,3',5,5'-tetracarboxydiphenylmethane 2 Carry out acylation reaction, obtain the compound with formula (I) structure.

[0040] The present invention uses isophthalic acid and paraformaldehyde as raw materials and sulfuric acid as a solvent to prepare 3,3', 5,5'-tetracarboxydiphenylmethane; then the 3,3', 5,5' -Tetracarboxydiphenylmethane is acylated to obtain a compound with formula (I), i.e. 3,3 ', 5,5'-tetraacyl diphenylmethane chloride, and the reaction formula is as follows:

[0041]

[0042] Firstly, isophthalic acid and paraformaldehyde are added into sulfuric acid for reaction to obtain 3,3',5,5'-tetracarboxydiphenylmethane. The temperature for the reaction between isophthalic acid and paraformaldehy...

Embodiment 1

[0078] Add 66.04g (0.4mol) of isophthalic acid to a three-necked flask equipped with a mechanical stirrer, condenser and water separator, then add 200mL of sulfuric acid dropwise therein, add 6.24g (0.2mol) of paraformaldehyde after heating to dissolve , heated to reflux at 150° C. for 10 h. After the reaction was completed, the resulting reaction mixture was poured into an ice-water mixture, filtered, dried, and purified to obtain 3,3′,5,5′-tetracarboxydiphenylmethane. The 3,3',5,5'-tetracarboxydiphenylmethane was added to the one-necked bottle, and SOCl was added 2 Acylation, steam off excess SOCl 2 Then cyclohexane was added into the one-necked bottle for washing to obtain 3,3',5,5'-tetraacyl chloride diphenylmethane.

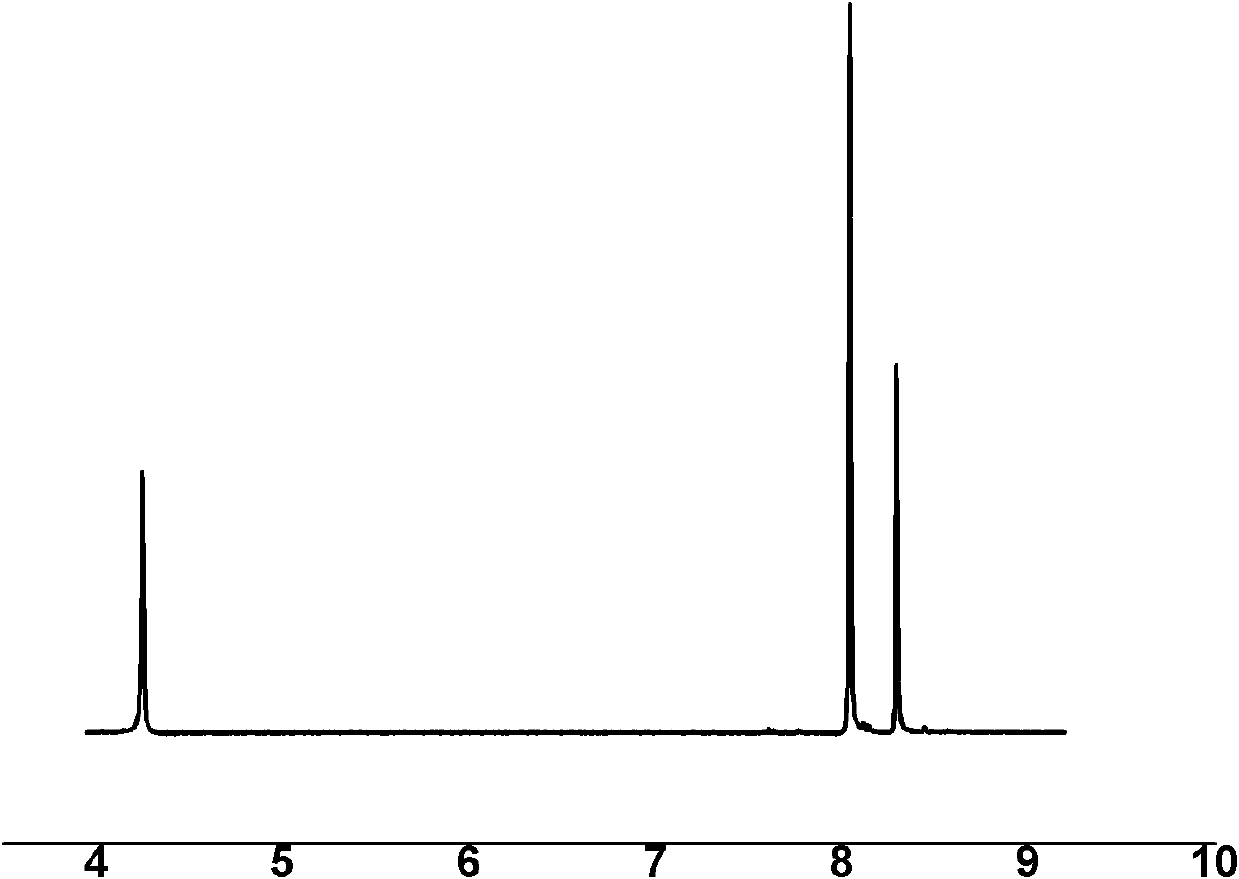

[0079] The 3,3', 5,5'-tetraacyl diphenylmethane chloride was analyzed by nuclear magnetic resonance, the results can be found in figure 1 , figure 1 For the nuclear magnetic resonance spectrum of the 3,3',5,5'-tetraacyl chloride diphenylmethane prepared i...

Embodiment 2

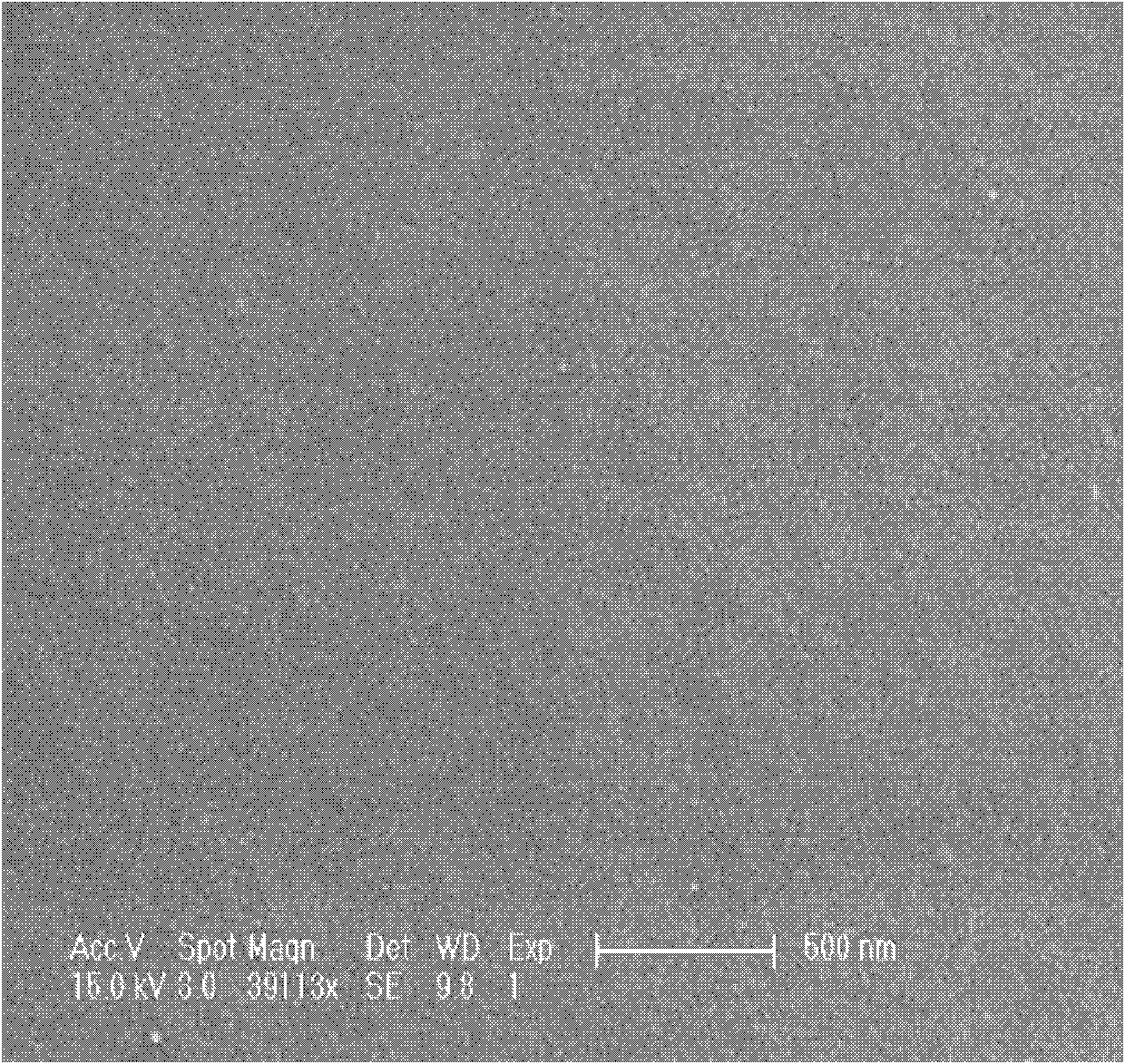

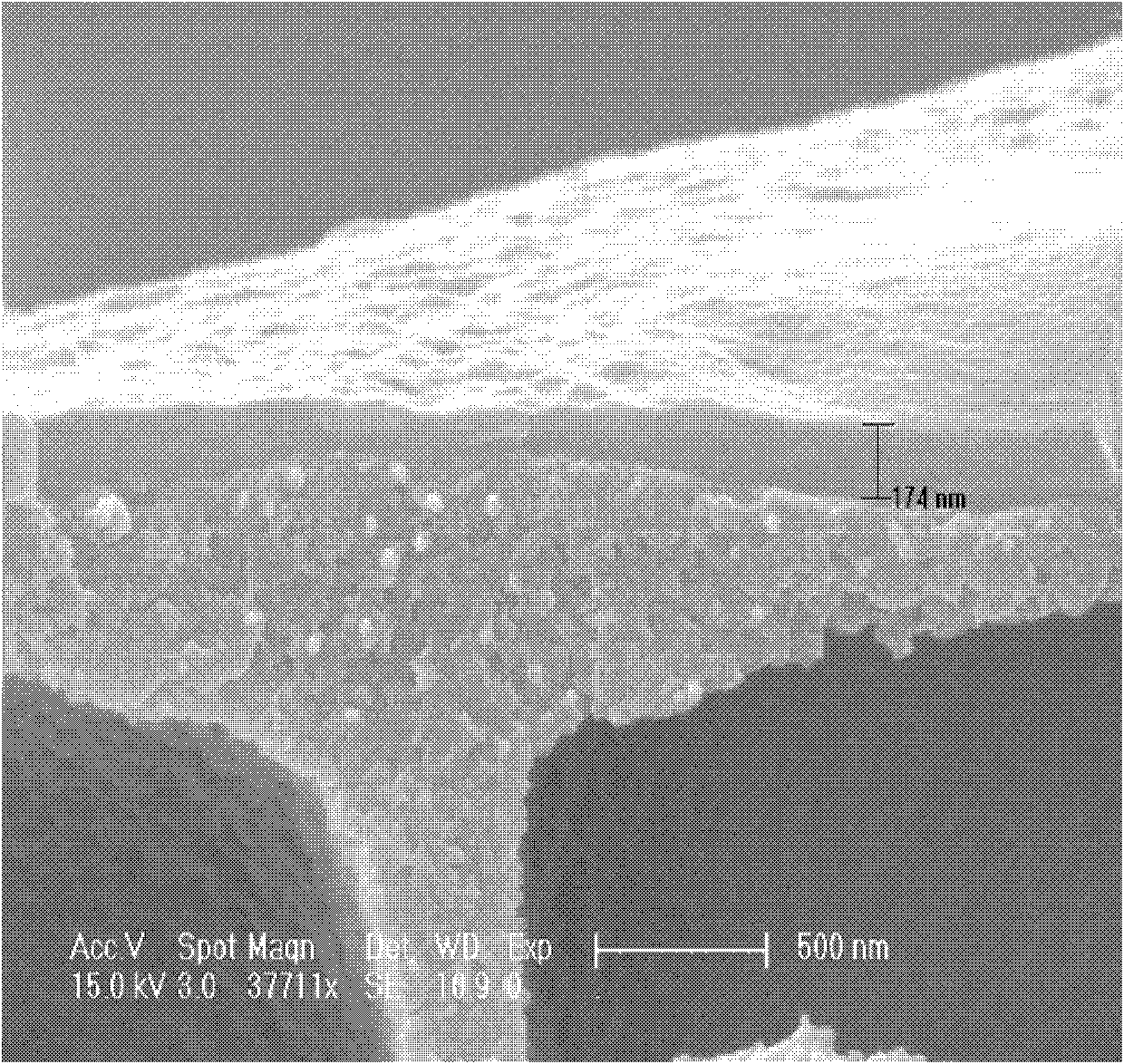

[0081] Polyacrylonitrile, polyvinylpyrrolidone and polyvinyl alcohol are dissolved in N, N-dimethylformamide to obtain a mixed solution. In the mixed solution, the mass concentration of polyacrylonitrile is 10%, and the mass concentration of polyvinylpyrrolidone The concentration is 15%, and the mass concentration of polyvinyl alcohol is 0.02%; the mixed solution is scraped on the polyester non-woven fabric, and then the non-woven fabric is immersed in water to obtain a polyacrylonitrile support layer; the polypropylene The molecular weight cut off (MWCO) of the nitrile support layer is about 20,000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water flux | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com