Immobilized whole-cell catalyst and its preparation method and application

A whole-cell catalyst and fixative technology, applied in biochemical equipment and methods, botany equipment and methods, applications, etc., can solve problems such as high cost and large pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

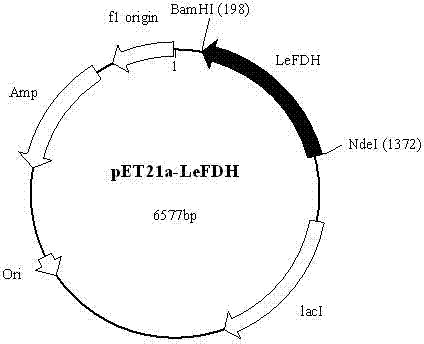

[0026] Preparation of whole-cell catalysts comprising D-lactate dehydrogenase from Staphylococcus epidermidis ATCC 12228 and formate dehydrogenase from Lodderomyces elongisporus NRRL YB-4239:

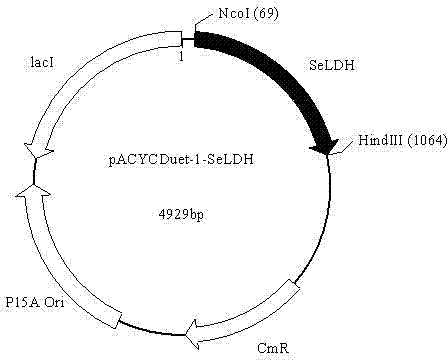

[0027] (1) Preparation of recombinant plasmid pACYCDuet-1-SeLDH:

[0028] Genomic DNA of Staphylococcus epidermidis was extracted according to the general method in the field ("Molecular Cloning Experiment Guide", Science Press, 3rd edition), and the D-type lactate dehydrogenase gene fragment was amplified using specific primers, and this fragment was used Restriction endonucleases NcoI and HindIII were used for double digestion, and the gene fragment was purified by agarose gel electrophoresis, ligated with pACYCDuet-1 digested by the same restriction enzyme, and transformed into E. coli host strain Top10 cells. The transformant was picked and inoculated into LB liquid medium, cultured at 37°C for 20 hours, and the recombinant plasmid was extracted with a plasmid extraction kit (Broadt...

Embodiment 2

[0041] Immobilized Whole Cell Preparation:

[0042] Dissolve 3.0 g of polyethylene glycol in 35 ml of water, add 5.0 g of polyvinyl alcohol (PVA) and raise the temperature to 90-95°C to dissolve. After the polyvinyl alcohol is completely dissolved, lower the temperature to 25°C-30°C, add 4 grams of recombinant cells (wet weight), mix well, use a disposable straw to absorb the mixture, and pour it on the plane to form a disc, and Incubate at 30°C for 1 to 1.5 hours. Transfer to 0.1M sodium sulfate solution to stabilize for 2 hours, filter dry and wash twice with water, and place in 10mM sodium phosphate buffer for use.

[0043] The cell immobilization reagent polyvinyl alcohol can also be replaced by polyacrylamide or calcium alginate with the same effect.

[0044]

Embodiment 3

[0046] Synthesis of (R)-2-hydroxy-4-phenyl-butyrate using a whole-cell catalyst comprising D-type lactate dehydrogenase and formate dehydrogenase:

[0047]Add 100 mM phosphate buffer (pH adjusted to 6.5), 40 g / L cell concentration (wet weight) whole-cell catalyst BL21(DE3) (pET21a-LeFDH, pACYCDuet-1-SeLDH) (containing Lactate dehydrogenase type D from Staphylococcus epidermidis and formate dehydrogenase from Lutheran yeast), (R)-2-hydroxy-4-phenyl-butyric acid sodium salt and 75 mM ammonium formate at a final concentration of 30 mM. The reaction mixture was stirred at 30°C for 1.5 hours. Samples were taken at regular intervals, and the amount of product formed was determined by HPLC. The conversion was greater than 99% after 1.5 hours of reaction. After the reaction was completed, the cells were recovered by centrifugation, the supernatant of the centrifuged liquid was acidified to pH 3 with 30% hydrochloric acid, extracted once with 120 ml of ethyl acetate, and then extract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com