Photonic crystal humidity sensor and preparation method thereof

A technology of humidity sensor and photonic crystal, which is applied in the direction of color/spectral characteristic measurement, etc., can solve the problems of complicated method, difficult to prepare large-size photonic crystal humidity sensor, complicated steps, etc., and achieve the effect of simple and convenient use method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The present invention also provides a method for preparing the photonic crystal humidity sensor, which includes the following steps:

[0044] a) Mix acrylamide monomer, N,N'-methylene bis(acrylamide), persulfate and superparamagnetic carbon-coated ferroferric oxide colloidal nanoparticles in ethylene glycol. Get a mixed solution;

[0045] b) Add N,N,N',N'-tetramethylethylenediamine to the mixed solution obtained in step a), and react under the action of an external uniform magnetic field to obtain a photonic crystal humidity sensor.

[0046] The present invention uses acrylamide monomer, N,N'-methylenebis(acrylamide), persulfate and superparamagnetic carbon-coated ferroferric oxide colloidal nanoparticles as raw materials. Under the catalysis of N',N'-tetramethylethylenediamine, acrylamide monomer, N,N'-methylenebis(acrylamide), and persulfate react to form polyacrylamide gel. At the same time, super The paramagnetic carbon-coated ferroferric oxide colloidal nanoparticles se...

Embodiment 1

[0068] Dissolve 0.3g of ferrocene in 30mL of acetone, add 1.5mL of hydrogen peroxide aqueous solution with a mass concentration of 30% dropwise after ultrasonic dispersion. After magnetic stirring at a speed of 1000r / min for 30min, a mixed solution is obtained; the mixing is easy Transfer to a 40mL autoclave, seal and heat to 200°C, keep for 72h, and cool to room temperature to obtain black powder; wash the black powder with acetone and ethanol 3 times, and dry it in a vacuum oven at 40°C for 6 hours to obtain super smooth Magnetic carbon-coated ferroferric oxide colloidal nanoparticles.

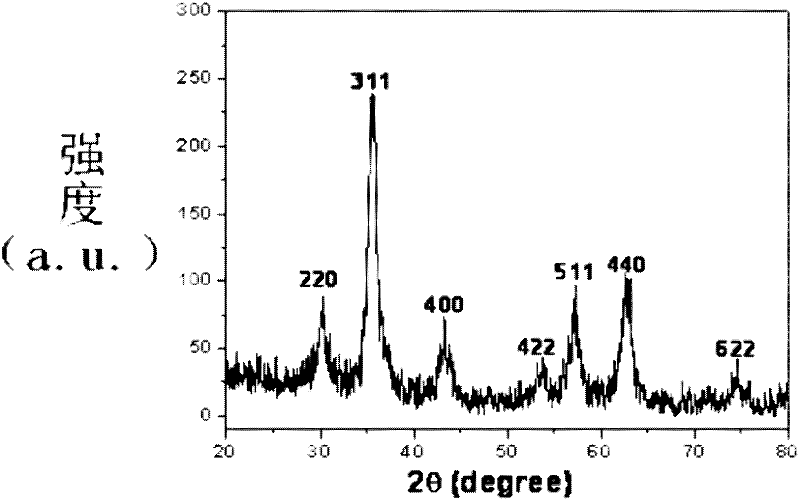

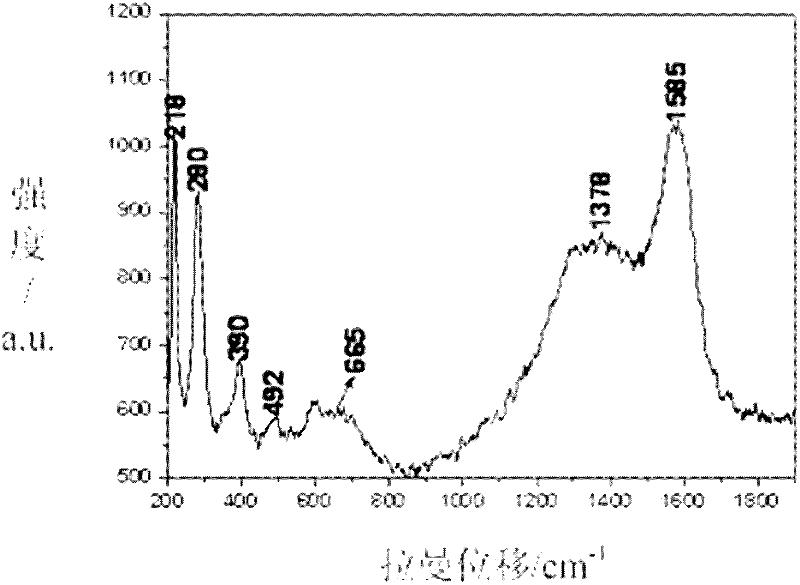

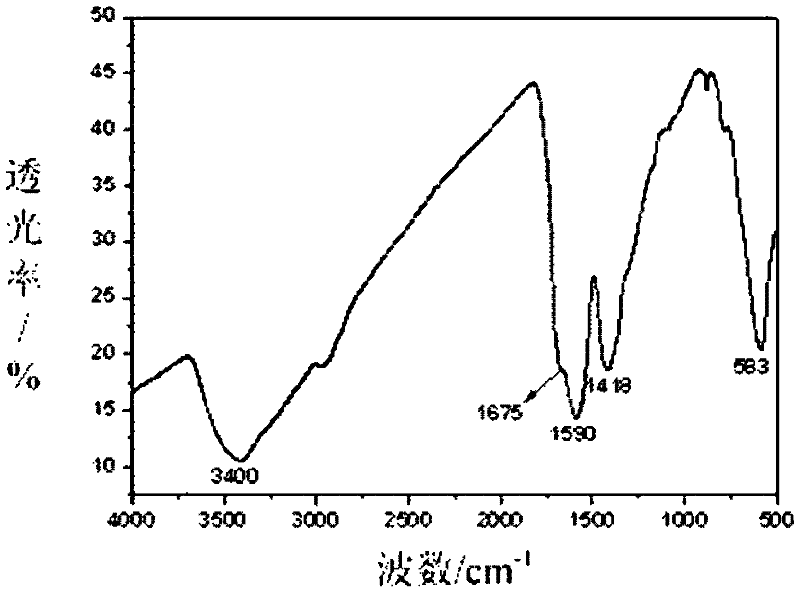

[0069] X-ray diffraction analysis was performed on the superparamagnetic carbon-coated ferroferric oxide colloidal nanoparticles, the results are shown in figure 1 , figure 1 This is the X-ray diffraction pattern of the superparamagnetic carbon-coated ferroferric oxide colloidal nanoparticles prepared in the embodiment of the present invention, which is represented by figure 1 It can be seen tha...

Embodiment 2

[0077] Dissolve 1.5g of acrylamide monomer, 0.05g of N,N'-methylenebis(acrylamide) and 0.02g of ammonium persulfate in 15mL of ethylene glycol, stir it evenly, add 0.04g of the prepared in Example 1 Superparamagnetic carbon-coated colloidal nanoparticles of ferroferric oxide are sonicated in an ice water bath at 0°C for 10 minutes to obtain a mixed solution;

[0078] Put 1.5mL of the mixed solution into a 5mL beaker, apply a uniform magnetic field of 0.1T under the beaker, and then add 20μL of N,N,N′,N′-tetramethylethylenediamine into the container, React for 30 seconds to obtain a photonic crystal humidity sensor.

[0079] Put the photonic crystal humidity sensor into a closed environment with different stable relative humidity values to observe the color of the photonic crystal humidity sensor, see Figure 7 with Figure 8 , Figure 7 Is the color of the photonic crystal humidity sensor provided by the embodiment of the present invention under different relative humidity, Figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Saturation magnetic field strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com