A kind of high temperature resistant alkaline anion exchange membrane and its preparation and application

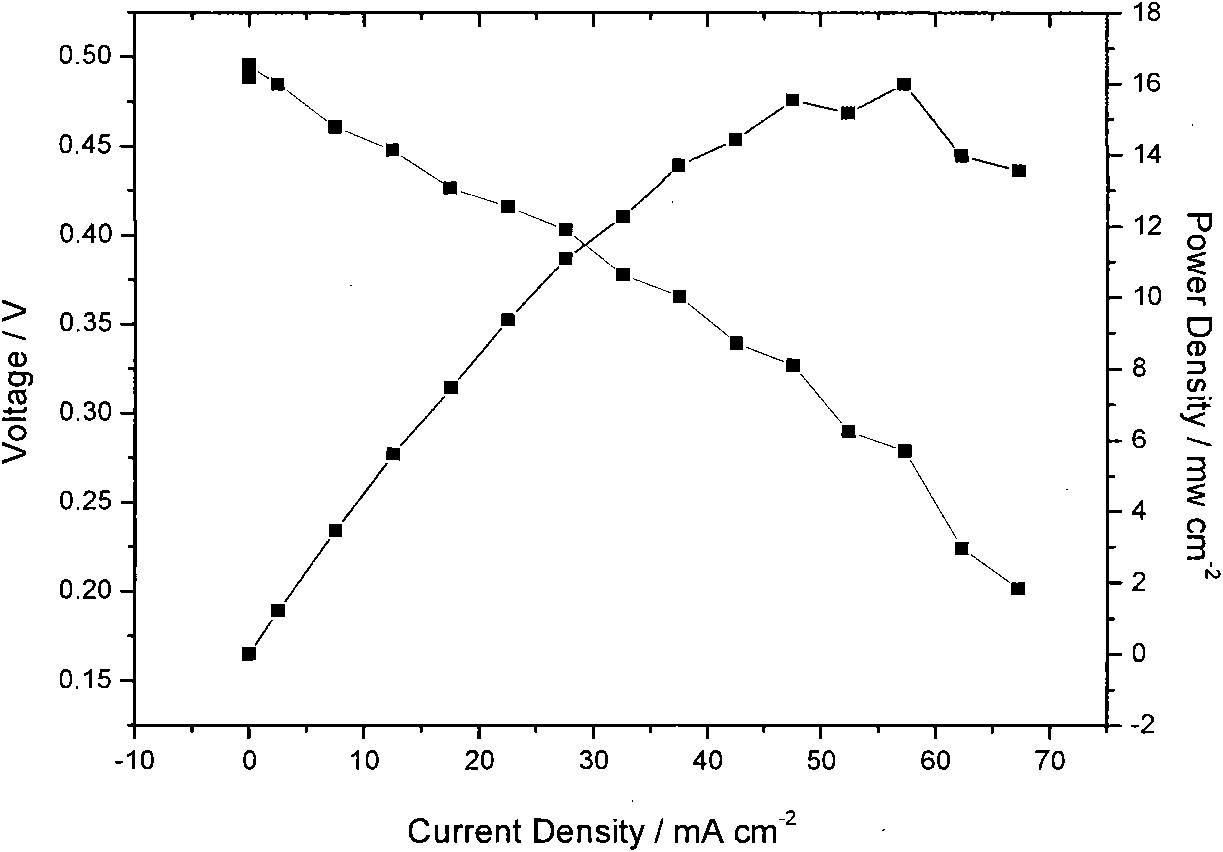

An alkaline anion, exchange membrane technology, applied in fuel cells, electrical components, electrochemical generators, etc., can solve the problems of poor electrochemical stability, low anion conductivity, easy loss of doped alkali, etc., and achieve good stability. , Overcome the effect of low anion conductivity, good thermal stability and electrochemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

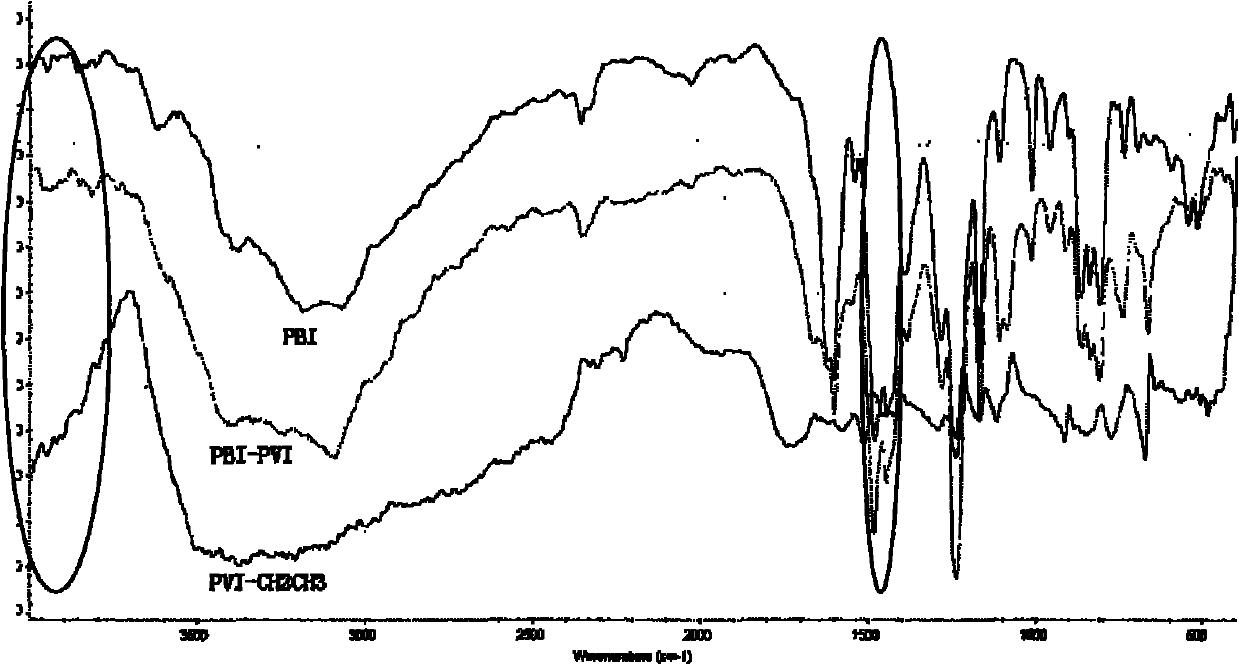

[0029] Synthesis of polyvinylimidazole: Dissolve 4g of 1-vinylimidazole and 0.05g of free radical initiator azobisisobutyronitrile in 5ml of toluene, heat at 75°C, stir with magnetic force, condense to reflux and pass into N 2 Protect. After reacting for 5 hours, the solvent was evaporated to obtain polyvinylimidazole.

[0030] Quaternization of polyvinylimidazole: Dissolve the obtained polyvinylimidazole in ethanol, add 6g bromoethane, stir magnetically at 75°C, condense and reflux and pass into N 2 Protected, reacted for 20 hours to make it quaternized. The solvent was evaporated to dryness to obtain poly-1-vinyl 3-ethylimidazole bromide as a solid substance

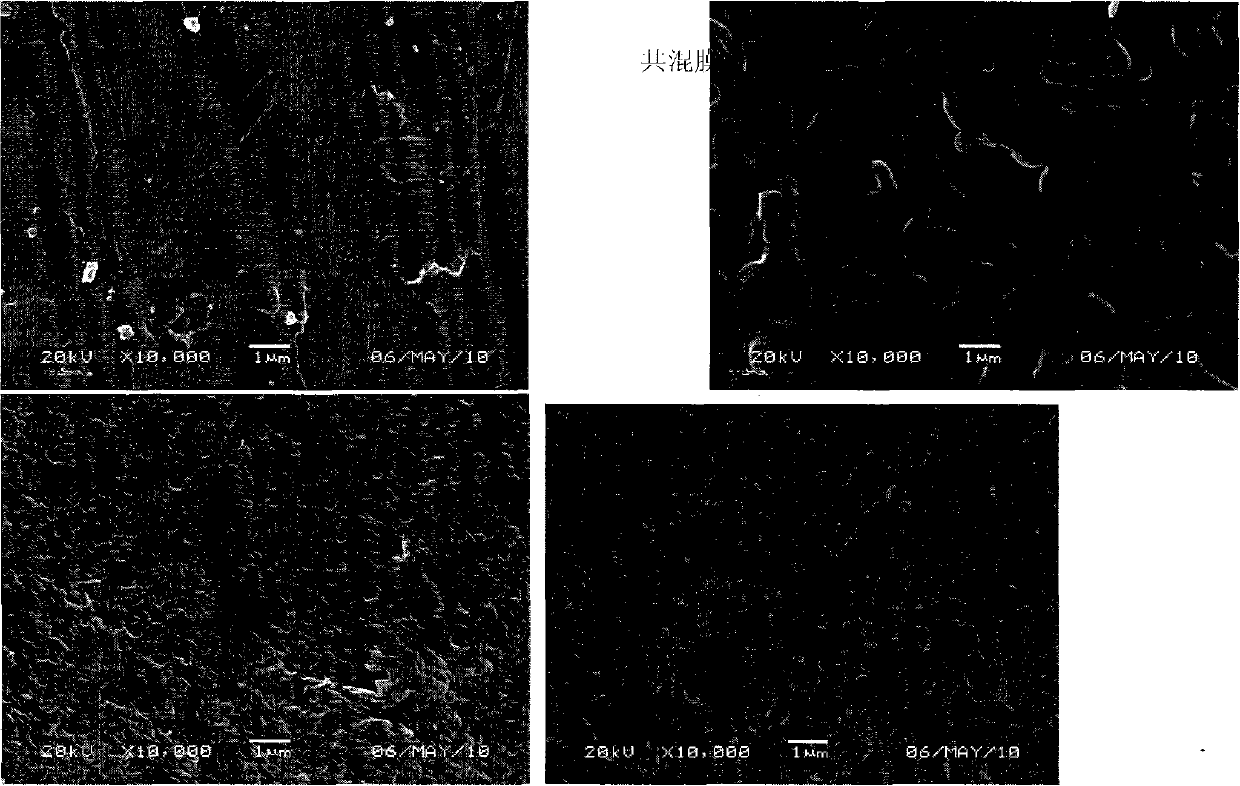

[0031] Preparation of blend film casting solution: take poly 1-vinyl 3-ethyl imidazolium bromide 25mg, add 10ml water, heat up to 60°C, stir magnetically to make it swell and dissolve. Take 25 mg of PBI (containing ether linkages), add it into N,N-dimethylacetamide, and raise the temperature slightly to dissolve...

Embodiment 2

[0043] Synthesis of polypropylene imidazole: dissolve 6g of 1-propenyl imidazole and 0.2g of free radical initiator azobisisoheptanonitrile in 8ml of benzene, heat at 80°C, stir with magnetic force, condense and reflux and pass into N 2 Protect. After reacting for 3 hours, the solvent was evaporated to dryness to obtain polypropylene imidazole.

[0044] Quaternization of polypropylene imidazole: Dissolve the obtained polypropylene imidazole in ethanol, add 10g of 1-chlorobutane, stir magnetically at 90°C, condense to reflux and pass into N 2 Protected, reacted for 30 hours to make it quaternized. The solvent was evaporated to dryness to obtain poly-1-propenyl 3-butylimidazole chloride as a solid substance.

[0045] Preparation of blend film casting solution: Take 40 mg of poly 1-propenyl 3-butyl imidazole chloride, add it to 12 ml of water, heat up to 50° C., and magnetically stir to make it swell and dissolve. Take 10 mg of polyethersulfone, add it to acetone, and raise th...

Embodiment 3

[0048] Synthesis of polyisobutenyl imidazole: Dissolve 8 g of isobutenyl imidazole and 0.64 g of free radical initiator dimethyl azobisisobutyrate in 30 ml of toluene, heat at 50 ° C, magnetically stir, condense and reflux and pass into N 2 Protect. After reacting for 12 hours, the solvent was evaporated to obtain polypropylene imidazole.

[0049] Quaternization of polyisobutenyl imidazole: Dissolve the obtained polypropenyl imidazole in ethanol, add 2g of chloropropane, stir magnetically at 65°C, condense and reflux and pass into N 2 protection, and reacted for 10 hours to make it quaternized. The solvent was evaporated to dryness to obtain poly-1-isobutenyl 3-propyl imidazole chloride as a solid substance.

[0050] Preparation of blend film casting solution: Take 40 mg of poly-1-isobutenyl 3-propyl imidazole chloride, add it to 4 ml of water, heat up to 80° C., and stir it magnetically to make it swell and dissolve. Take 20 mg of polyetheretherketone, add it into N-methyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com