Water emulsion pesticide system and preparation method thereof

A water emulsion and pesticide technology, applied in the field of pesticides and water emulsion pesticides, can solve the problem that emulsifier has not yet been found, and achieve excellent suspension effect, good suspension stability, and the effect of preventing agglomeration or aggregation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

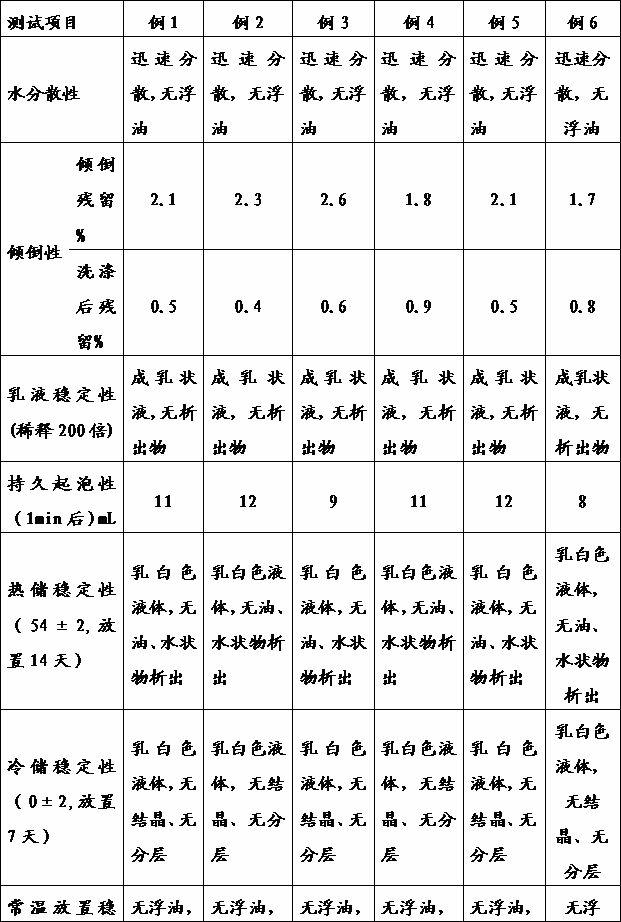

Examples

Embodiment 1

[0038] Example 1 (the original drug is the water emulsion system of chlorpyrifos)

[0039] 1. Formula (based on a total of 100 kg):

[0040] Component Amount added (kg) Chlorpyrifos 40 polymer emulsifier 4 POE (20) Sorbitan Trioleate 5 Xylene 10 water add to 100

[0041] The polymer emulsifier is an amphiphilic polymer with a micro-crosslinked structure obtained by inverse emulsion polymerization with acrylic acid / acryl ammonium chloride / acrylamide at a molar ratio of 1:0.4:0.4. , PH value is 7.1, 1% deionized water dispersion viscosity is 8300mPa·s, relative molecular weight is about 16 million.

[0042] 2. Preparation method:

[0043] (1) Mix xylene and the original drug chlorpyrifos evenly according to the above formula, and then mix evenly with 3 kg of POE (20) sorbitan trioleate, which is the oil phase;

[0044] (2) Mix the polymer emulsifier and the remaining POE (20) sorbitan trioleate evenly, make up the water in the for...

Embodiment 2

[0046] Embodiment 2 (the original drug is the water emulsion system of fenbutatin)

[0047] 1. Formula (based on a total of 100 kg)

[0048] Component Amount added (kg) Phentermine 10 polymer emulsifier 3 lanolin alcohol 1 POE(4) nonylphenol ether 5 No. 5 white mineral oil 15 Ethylene glycol 3 water add to 100

[0049] The high molecular emulsifier is an amphiphilic polymer with a micro-crosslinked structure obtained by inverse emulsion polymerization with a molar ratio of isooctyl acrylate / acryl ammonium chloride / methacrylamide in a ratio of 1:0.1:0.2. The viscosity of the polymer at 25°C, pH value 6.8, 1% deionized water dispersion is 6800mPa·s, and the relative molecular weight is about 12 million.

[0050] 2. Preparation method:

[0051] (1) According to the above formula, mix No. 5 white mineral oil and the original drug phenbutyltin evenly, then mix evenly with 1 kg of lanolin alcohol, add 2 kg of POE (4) nonylp...

Embodiment 3

[0054] Example 3 (Water-emulsion system in which the original drug is Fofenol·Hexythiazox)

[0055] 1. Formula (based on a total of 100 kg)

[0056] Component Amount added (kg) Fofenol·Hexythiazox 20 polymer emulsifier 1.5 POE(2) oleyl ether 1 PEG400 monolaurate 3 acetone 7 Propylene Glycol 4 water add to 100

[0057] The polymer emulsifier is an amphiphilic polymer with a micro-crosslinked structure obtained by solution polymerization with behenyl acrylate / dimethyldiallyl ammonium chloride at a molar ratio of 1:0.3. At 25°C, pH value is 7.1, viscosity of 1% deionized water dispersion is 5200mPa·s, relative molecular weight is about 1 million.

[0058] 2. Preparation method:

[0059] (1) According to the above formula, mix the acetone and the original drug Fenmethoxol·Hexythiazox evenly, and then mix evenly with 1 kg of POE (2) oleyl alcohol ether, add 1 kg of PEG400 monolaurate, mix evenly, and it is oil Mutually; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com