Barium strontium titanate dielectric film prepared through micro-arc oxidation and method thereof

A technology of micro-arc oxidation and barium strontium titanate, applied in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve problems such as few dielectric films, single types of films, undisclosed performance parameters, etc., and achieve equipment investment Small size, excellent dielectric properties, and convenient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

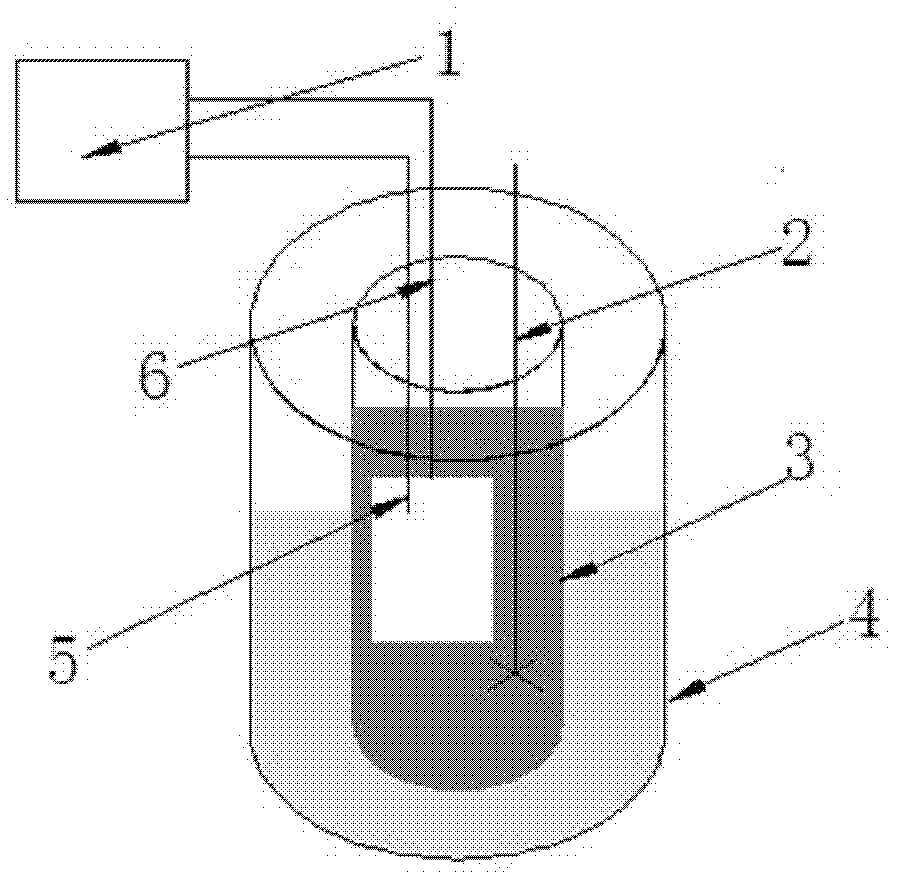

Method used

Image

Examples

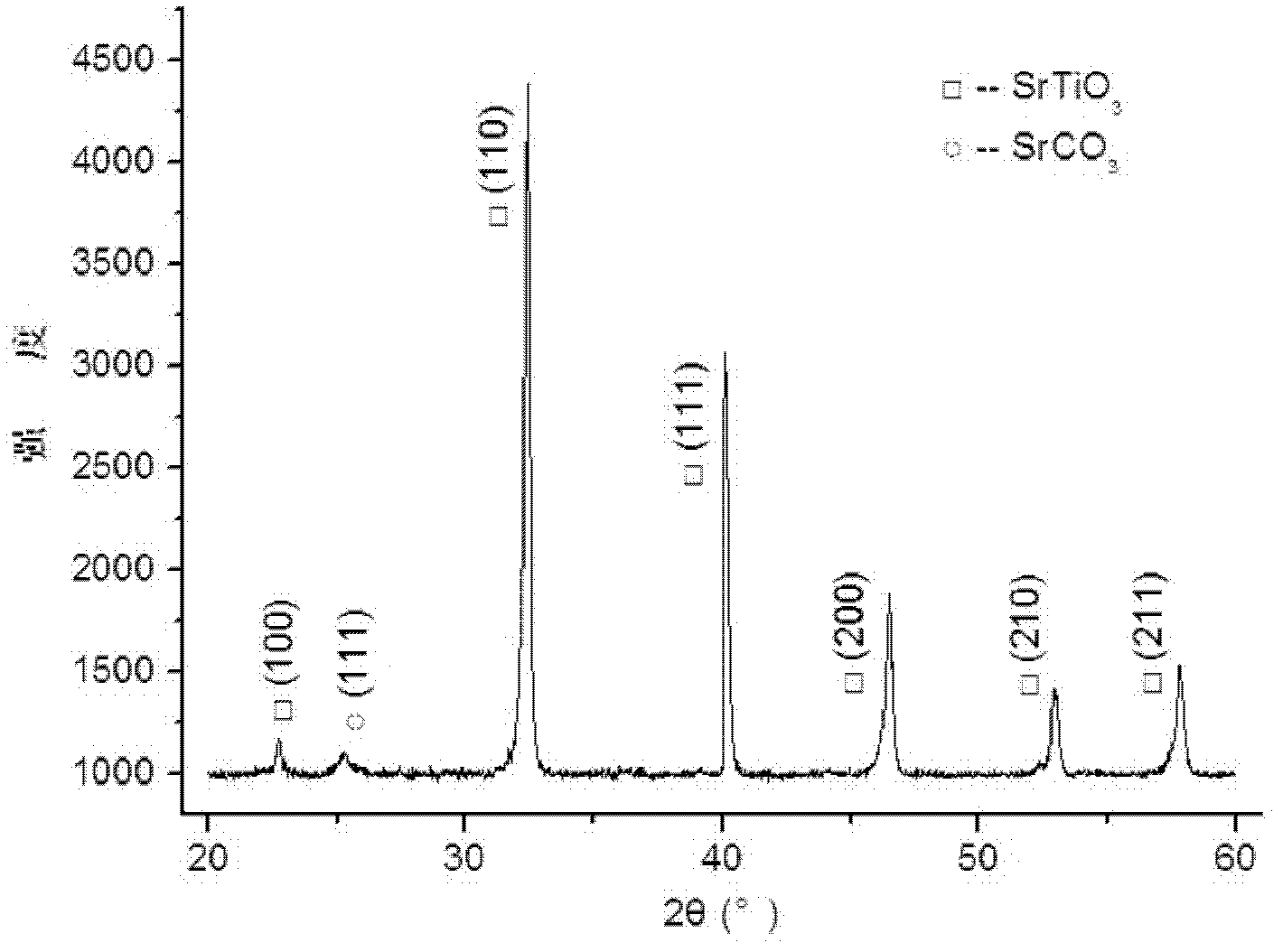

Embodiment 1

[0031] (1) Configure the electrolyte: Sr(CH 3 COO) 2 The solution is electrolyte, the volume of electrolyte is 400mL, the solution concentration is 0.4mol / L, it is stirred evenly on the electromagnetic heating stirrer, the heating temperature is set to 60°C, and the stirring time is 20min.

[0032] (2) Set the electrical parameters of the DC micro-arc oxidation power supply: DC pulse power supply is used, the pulse waveform is square wave, the mode is constant current mode; the current density is 20A / dm 2 (The size of the substrate Ti is 20mm*20mm*2.5

[0033] mm, Ti element Wt% is 96.47%), the pulse frequency is 100Hz, the duty cycle is 85%; the processing time is 25min.

[0034] (3) Micro-arc oxidation treatment: After the Ti substrate is polished with sandpaper, it is pretreated with a mixture of hydrofluoric acid and nitric acid at a volume ratio of 1:3, and then washed in acetone and distilled water respectively, and dried. The Ti matrix is connected to the anode and...

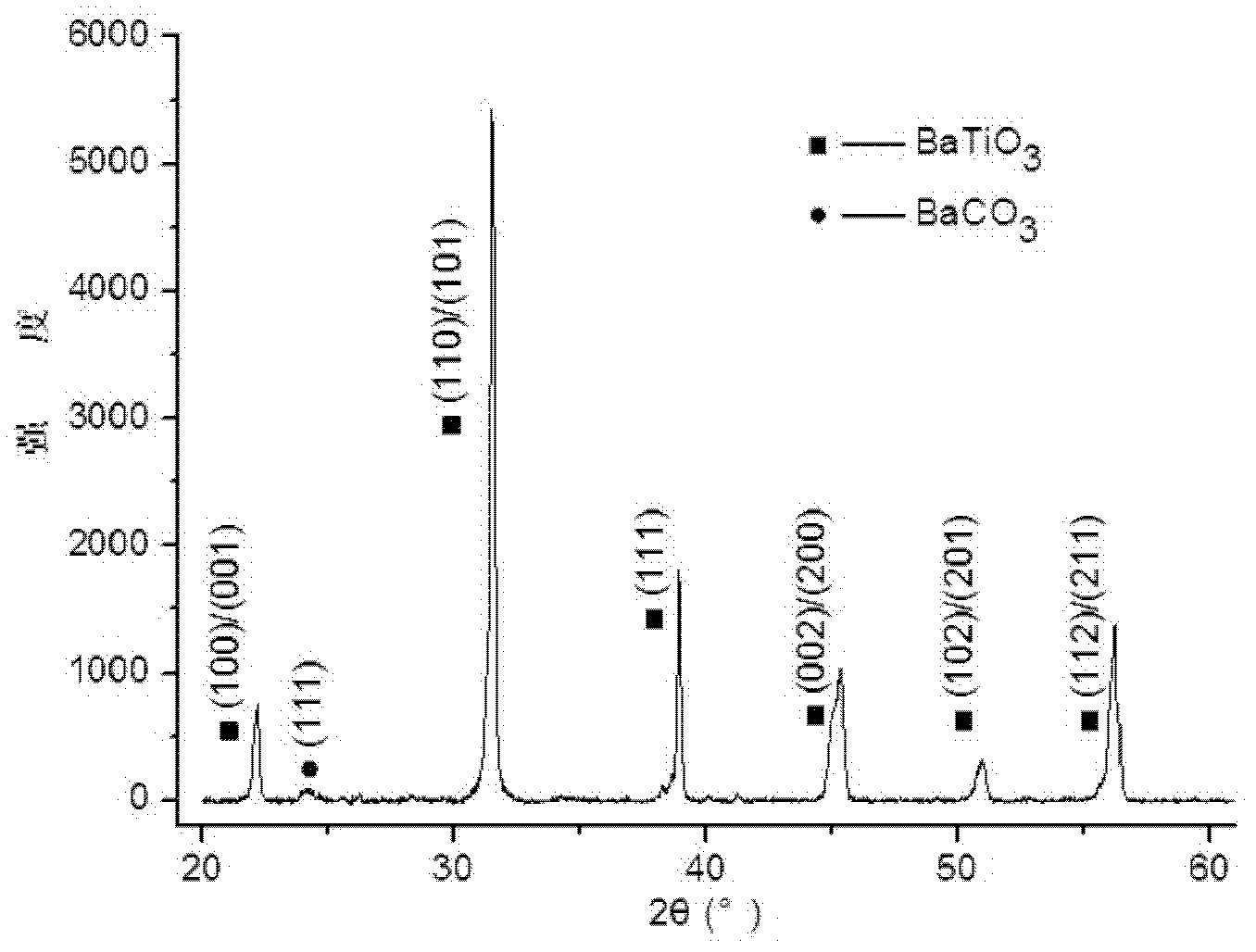

Embodiment 2

[0037] (1) Configure the electrolyte: Ba(CH 3 COO) 2 The solution is an electrolyte, the volume of the electrolyte is 400mL, the molar concentration of the solution is 0.6mol / L, it is evenly stirred on an electromagnetic heating stirrer, the heating temperature is set to 60°C, and the stirring time is 15min.

[0038] (2) Set the electrical parameters of the DC micro-arc oxidation power supply: DC pulse power supply is used, the pulse waveform is square wave, the mode is constant current mode; the current density is 15A / dm 2 (The size of the substrate Ti is 20mm*20mm*2.5

[0039] mm, Ti element Wt% is 96.35%), the pulse frequency is 200Hz, the duty cycle is 85%; the processing time is 25min.

[0040](3) Micro-arc oxidation: After the Ti substrate is polished with sandpaper, it is pretreated with a mixture of hydrofluoric acid and nitric acid at a volume ratio of 1:3, and then washed in acetone and distilled water respectively, and the Ti substrate is dried. Connect to the an...

Embodiment 3

[0043] (1) Preparation of electrolyte: Ba(CH 3 COO) 2 and Sr(CH at a molar concentration of 0.3mol / L 3 COO) 2 Solution, the mixed solution mixed at a molar ratio of 1:1 is the electrolyte solution, the solution volume is 400mL, stirred evenly on an electromagnetic heating stirrer, the heating temperature is set to 60°C, and the stirring time is 20min.

[0044] (2) Set the electrical parameters of the DC micro-arc oxidation power supply: DC pulse power supply is used, the pulse waveform is square wave, the mode is constant current mode; the current density is 20A / dm 2 (The size of the substrate Ti is 20mm*20mm*2.5

[0045] mm, Ti element Wt% is 95.47%), the pulse frequency is 100Hz, the duty cycle is 85%; the processing time is 25min.

[0046] (3) Micro-arc oxidation: After the Ti substrate is polished with sandpaper, it is pretreated with a mixture of hydrofluoric acid and nitric acid at a volume ratio of 1:3, and then washed in acetone and distilled water respectively, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com