Method for improving efficiency of screening of 1,3-propylene glycol fusion bacteria

A technology for screening efficiency and propylene glycol, applied in the field of industrial biology, can solve problems such as lack and interference, and achieve the effect of improving the chance of success, reducing interference, and improving economic and economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

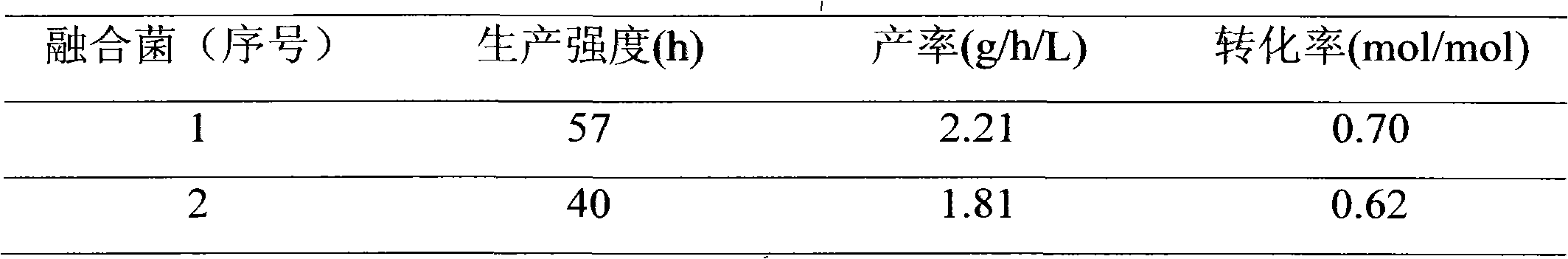

[0036] Example 1 Genome rearrangement breeding, using Klebsiella pneumoniae as the initial parent bacterial strain

[0037] Bacterial species: Klebsiella pneumoniae was screened by Fushun Petrochemical Research Institute and preserved in China Microorganism Culture Collection Center (CGMCC), No. 0798.

[0038] Regeneration medium (solid): A, sucrose 171.5g / L, tryptone 10g / L, glucose: 10g / L, yeast extract 5g / L, MgCl 2 4.273g / L, NaCl 5g / L, agar 15g / L.

[0039] LB medium (solid): tryptone 10g / L, yeast extract 5g / L, NaCl 5g / L, agar 15g / L.

[0040] Lysozyme: Dissolve lysozyme with 10mM / L Tris-Cl (pH8.0), make it into a 20mg / mL stock solution, and divide it for use.

[0041] SMM buffer: 0.5mol / L sucrose, 0.02mol / L MgCl, 0.02mol / L maleic acid.

[0042] Tris-Cl buffer: also contains 0.01mol / L EDTA, 0.5mol / L sucrose.

[0043] Feed fermentation medium: yeast extract 5g / l, K 2 HPO 4 ·3H 2 O 10g / l, KH 2 PO 4 2g / l, NH 4 Cl0.8-1g / l, NaCl 0.5g / l, MgSO 4 ·7H 2 O 0.1g / l, FeCl 3 ...

Embodiment 2

[0056] Example 2 Using Klebsiella pneumoniae and Escherichia coli as parent strains, genome rearrangement technology breeding

[0057] Klebsiella pneumoniae and Escherichia coli were selected as parental strains, pre-activated with LB liquid medium for 14 hours, and the parental strains (Klebsiella pneumoniae and Escherichia coli) were subjected to UV mutagenesis and NTG mutagenesis respectively. The enzymatically detached protoplasts were filtered through a filter membrane with a pore diameter of 0.75 μm to remove bacteria, and then filtered through a filter membrane of 0.25 μm to remove bacterial fragments, followed by subsequent operations such as protoplast inactivation and fusion. The remaining steps and methods are the same as in Example 1. After 1 to 3 rounds of genome rearrangement screening, strains with excellent performance can be obtained.

Embodiment 3

[0058] Example 3 Using Klebsiella pneumoniae and Klebsiella oxytoca as parent strains, genome rearrangement technology breeding

[0059] Klebsiella pneumoniae and Klebsiella oxytoca were selected as parental strains, pre-activated with LB liquid medium for 14 hours, and the parental strains (Klebsiella pneumoniae and Escherichia coli) were subjected to UV mutagenesis and NTG induction respectively. Change. The inactivated protoplasts were filtered through a filter membrane with a pore diameter of 0.45 μm to remove bacteria, and then filtered through a filter membrane of 0.25 μm to remove bacterial fragments, followed by subsequent operations such as protoplast fusion. The remaining steps and methods are the same as in Example 1. After 1 to 3 rounds of genome rearrangement screening, strains with excellent performance can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com