Insulation particles of three-dimensional electrode reactor and preparation and application method thereof

A technology of insulating particles and three-dimensional electrodes, which is applied in chemical instruments and methods, insulators, electrochemical water/sewage treatment, etc. Limitations and other issues to achieve the effect of shortening the migration distance, increasing the effective electrode area, and low thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

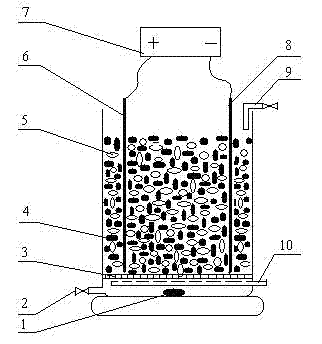

Image

Examples

preparation example Construction

[0027] A method for preparing insulating particles of a three-dimensional electrode reactor, the steps comprising:

[0028] (1) Pretreatment of the particle electrode: Soak the particle electrode after removing surface dirt in distilled water for 8-12 hours, rinse it several times, put it in a beaker, boil it for 10-15 minutes, let it cool down, filter out the water, put it in Dry in an oven for later use;

[0029] (2) Immersion coating, dehydration and cyclization: immerse the particle electrode treated in step (1) in the polyamic acid solution for 0.5-1 hour, after slight stirring, take out the particle electrode and spread it on the screen or glass or Form a polyamic acid film on the surface of the particle electrode on a ceramic plate, then place the particle electrode in a vacuum oven, raise the temperature in the oven to 110°C-150°C and keep it warm for 30-50min to remove the solvent from the particle electrode, continue Raise the temperature in the oven to 220°C-3...

Embodiment 1

[0032] Remove the dirt on the surface of the activated carbon particle electrode with a diameter of 3 mm and a length of 5 mm, soak it in distilled water for 8 hours, rinse it twice, put it in a beaker and boil it for 10 minutes, let it cool down, filter out the water, and dry it in an oven. Add the dried activated carbon particle electrode to the polyimide solution, dip for 0.6h, stir slightly for 2min, continue dipping for 0.2h, take it out and spread it on a stainless steel screen, put it in a vacuum oven, heat up to 110 °C Keep warm for 30 minutes, continue to heat up to 280 °C and keep warm for 60 minutes, take it out and let it cool down to room temperature, then add it to the polyimide solution, repeat the above dipping coating and vacuum drying process once to get polyimide coating activated carbon insulating particles .

Embodiment 2

[0034] Soak the 4mm×4mm×7mm graphite particle electrode in distilled water for 10h to remove the surface dirt, rinse it once, put it in a beaker and boil it for 12min, let it cool down, filter out the water and put it in an oven for drying. Add the dried graphite particle electrode into the polyimide solution, dip for 0.5h, stir gently for 2min, continue dipping for 0.5h, take it out and spread it on a porcelain plate, put it in a vacuum oven, heat up to 120 °C Keep warm for 30 minutes, continue to heat up to 320 °C and keep warm for 90 minutes, take it out and let it cool down to room temperature, then add it to the polyimide solution, repeat the above dipping coating and vacuum drying process once to get polyimide coating graphite insulating particles .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com