Foliar fertilizer and preparation method thereof

A foliar fertilizer and surfactant technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve problems such as lack of foliar fertilizer, and achieve the effects of increasing the attachment area, convenient use, and improving absorption and utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

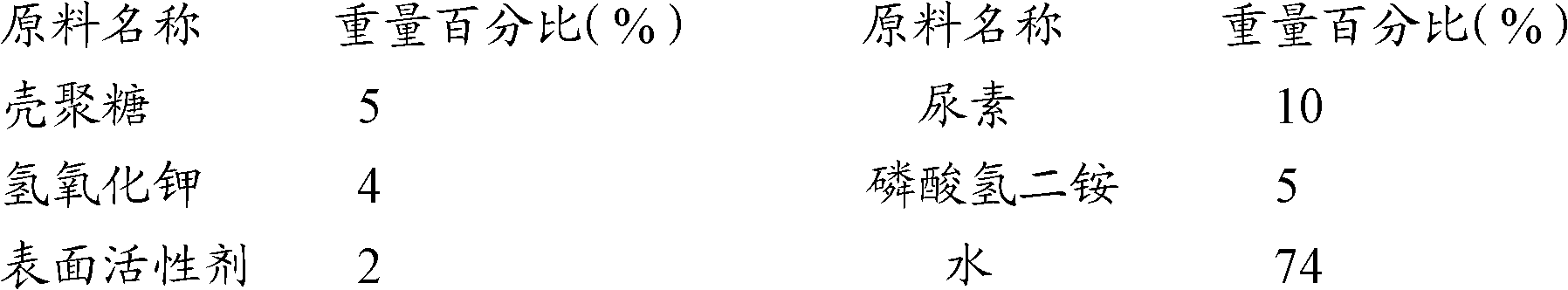

[0033] Embodiment 1: the preparation of foliar fertilizer of the present invention

[0034]

[0035] Raw material chitosan preparation:

[0036] Dissolve 100 kg of chitin in 750 kg of 1% acetic acid aqueous solution, then add 60 kg of 15% hydrogen peroxide aqueous solution, heat up to 50°C, degrade for 3 hours, and dry for use.

[0037] Detect the average molecular weight of the chitosan that makes with liquid chromatography, detection condition is as follows:

[0038] Mobile phase and stationary phase are chromatographic grade tetrahydrofuran and n-hexane; CGX 500 silica gel column with a particle size of 10 μm and a pore size of Adopt a L-7100 isocratic pump, which is connected with a L-7400UV detector, both produced by Hitachi, the detection wavelength is 260nm, the 7100-type sampling valve, the quantitative tube is 20μL, between the sampling valve and the pump The length of the connecting tube is 120mm, the volume is 12μL; the data collection is through D-7000HPLC s...

Embodiment 2

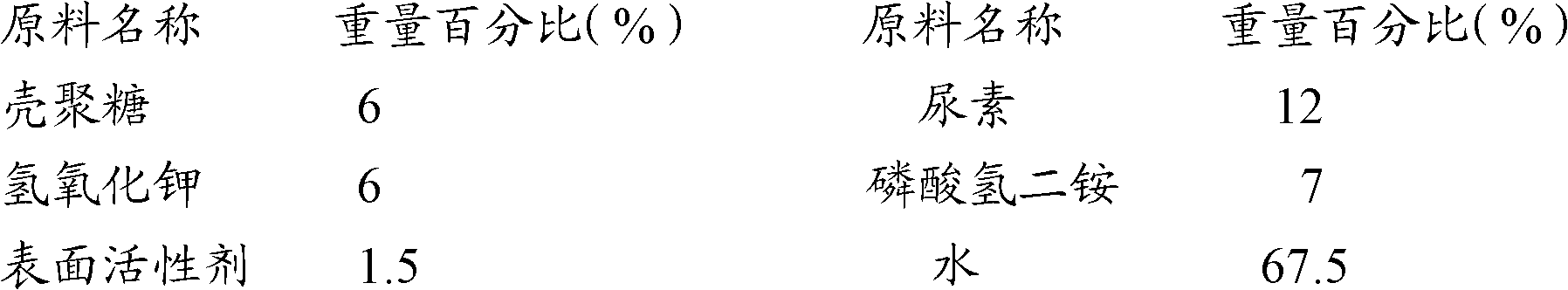

[0041] Embodiment 2: the preparation of foliage fertilizer of the present invention

[0042]

[0043] Raw material chitosan preparation:

[0044] Dissolve 80 kg of chitin in 880 kg of 1% acetic acid aqueous solution, then add 70 kg of 10% hydrogen peroxide aqueous solution, heat up to 40°C, degrade for 2.5 hours, and dry for later use.

[0045] The average molecular weight of the prepared chitosan is detected by liquid chromatography, and the detection conditions are as shown in Example 1. The measured average molecular weight of the prepared chitosan is 5000-6000 Daltons.

[0046] Raw material ABS preparation:

[0047] 250 kg of dodecylsulfonic acid was dissolved in 600 kg of water, then 40 kg of sodium hydroxide was added, stirred for 2 hours, and reserved for subsequent use.

[0048] The preparation method of foliage fertilizer of the present invention:

[0049] 60 kilograms of chitosan prepared according to the above method, 120 kilograms of urea, 60 kilograms of ...

Embodiment 3

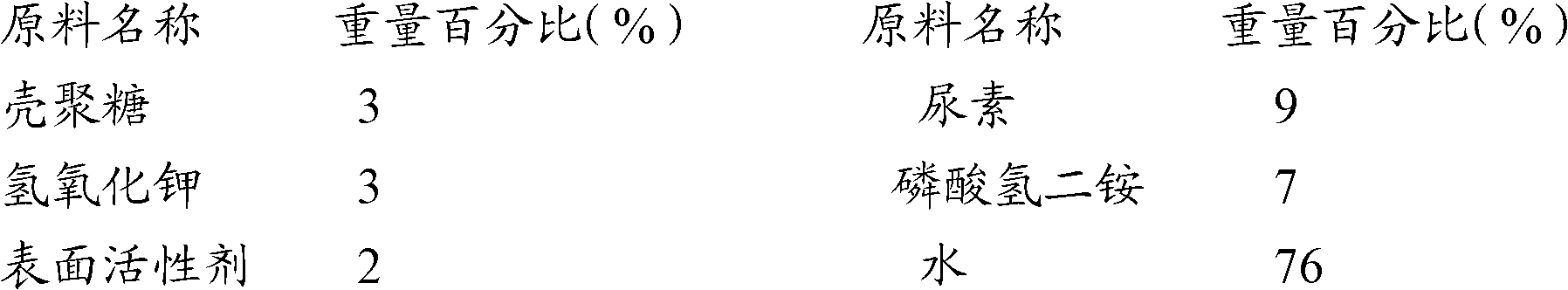

[0050] Embodiment 3: the preparation of foliar fertilizer of the present invention

[0051]

[0052] Raw material chitosan preparation:

[0053] Dissolve 120 kg of chitin in 840 kg of 1% acetic acid aqueous solution, then add 80 kg of 20% hydrogen peroxide aqueous solution, heat up to 60°C, degrade for 3 hours, and dry it for later use.

[0054] The average molecular weight of the prepared chitosan is detected by liquid chromatography, and the detection conditions are as shown in Example 1. The average molecular weight of the prepared chitosan was measured to be about 6000.

[0055] Raw material ABS preparation:

[0056] 280 kg of dodecylsulfonic acid was dissolved in 680 kg of water, then 45 kg of sodium hydroxide was added, stirred for 3 hours, and reserved for subsequent use.

[0057] The preparation method of foliage fertilizer of the present invention:

[0058] 30 kilograms of chitosan prepared according to the above method, 90 kilograms of urea, 30 kilograms of po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com