Nonionic aqueous polyurethane emulsion and preparation method thereof

A water-based polyurethane and non-ionic technology, applied in the field of polymer materials, can solve the problems of large amount of non-ionic chain extenders, unstable non-ionic emulsion, and insufficient stability of the emulsion, and achieve good placement stability, large application range, good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

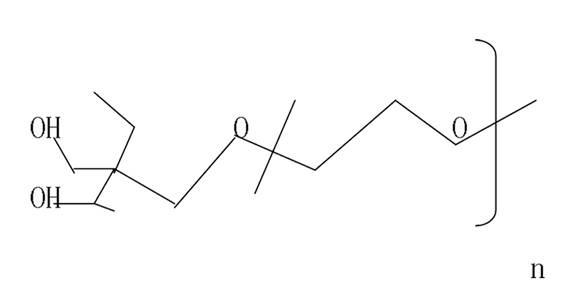

Image

Examples

Embodiment 1

[0039] Taking the production of about 300 kg of non-ionic water-based polyurethane emulsion as an example, the ratio of raw materials adopts the lower limit value, and the low-level varieties of small molecule chain extenders and amine neutralizers are used as raw materials such as diethylene glycol and isophorone diamine.

[0040] formula:

[0041] 71.8kg of polytetramethylene ether glycol with a number average molecular weight of 2000 and a hydroxyl value of 56.5KOH㎎ / g, 22kg of isophorone diamine diisocyanate, 0.2kg of diethylene glycol, and linear polyethylene glycol Diol bifunctional methyl ether 4㎏, dimethylolpropionic acid 1.2kg, trimethylolpropane 0.6kg, acetone 38.4kg, stannous octoate 0.03kg, dimethylaminoethanol 0.8kg, deionized water 205kg, iso 1.2kg of phoerone diamine, 0.4kg of water-based wetting agent (that is, the German high company 440), and 0.4kg of water-based leveling agent (that is, the German high company 440).

[0042] Preparation Process:

[0043] 1....

Embodiment 2

[0049] Taking the production of about 270 kg of non-ionic water-based polyurethane emulsion as an example, the formula ratio of raw materials adopts an intermediate value, and the lower varieties of raw materials of small molecule chain extender and amine neutralizer are 1.4 cyclohexanedimethanol and ethylenediamine.

[0050] formula:

[0051] Polycarbonate diol with a number average molecular weight of 2000 and a hydroxyl value of 57.4KOH㎎ / g: 61.5㎏, 4.4 cyclohexyl-methyl-diisocyanate 29.4㎏, 1.4 cyclohexanedimethanol 0.8㎏, linear polyethylene glycol Alcohol bifunctional methyl ether 6kg, dimethylolpropionic acid 1.6kg, trimethylolpropane 0.72kg, acetone 48kg, stannous octoate 0.06kg, dimethylaminoethanol 1.06kg, deionized water 165kg, ethylene glycol 3.6kg of amine, 1.2kg of water-based wetting agent (that is, High Company 440 in Germany), and 1.2kg of water-based leveling agent (that is, High Company 440 in Germany).

[0052] Process:

[0053] 1. Prepolymerization: Under th...

Embodiment 3

[0059] Taking the production of about 230 kg of non-ionic water-based polyurethane emulsion as an example, the upper limit is adopted for the formula ratio of raw materials, and the lower varieties of diethylene glycol and isophorone diamine are used as raw materials for small molecule chain extenders and amine neutralizers.

[0060] formula:

[0061] 51.8kg of polytetramethylene ether glycol with a number average molecular weight of 2000 and a hydroxyl value of 56.5KOH㎎ / g, 36kg of isophorone diamine diisocyanate, 1.2kg of diethylene glycol, and linear polyethylene glycol Diol bifunctional methyl ether 8kg, dimethylolpropionic acid 2kg, trimethylolpropane 1kg, acetone 57.6kg, stannous octoate 0.09kg, dimethylaminoethanol 1.3kg, deionized water 125kg, iso 6 kg of phoerone diamine, 2 kg of water-based wetting agent (that is, the German high company 440), and 2 kg of water-based leveling agent (that is, the German high company 440).

[0062] Preparation Process:

[0063] 1. Pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com