Micro-nano multi-scale patterned anticoagulation composite biological material and method for preparing same

A composite biomaterial and anticoagulation technology, applied in the field of composite biomaterials and their preparation, can solve the problems of insufficient biocompatibility for medical applications, poor mechanical properties, etc., and achieve the effect of improving anticoagulant performance and reducing thrombus.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

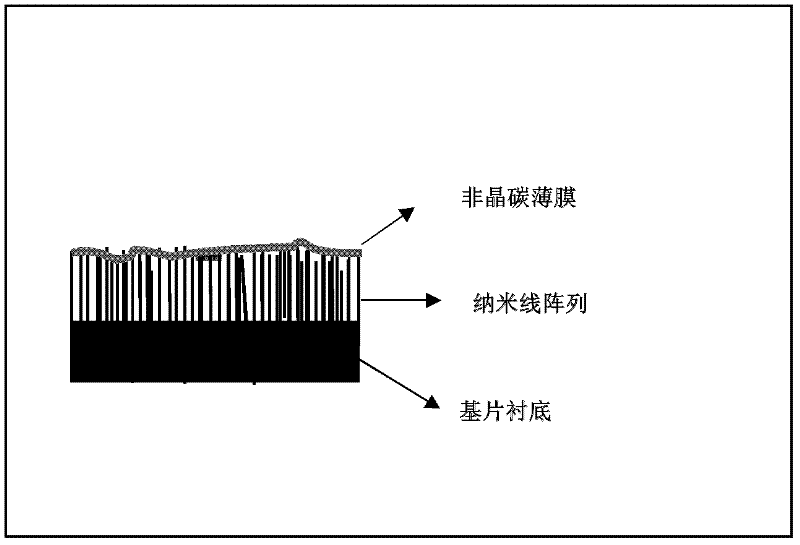

[0030] TiO of the present invention 2 The preparation method of nanowire / amorphous carbon film composite material comprises the following process steps:

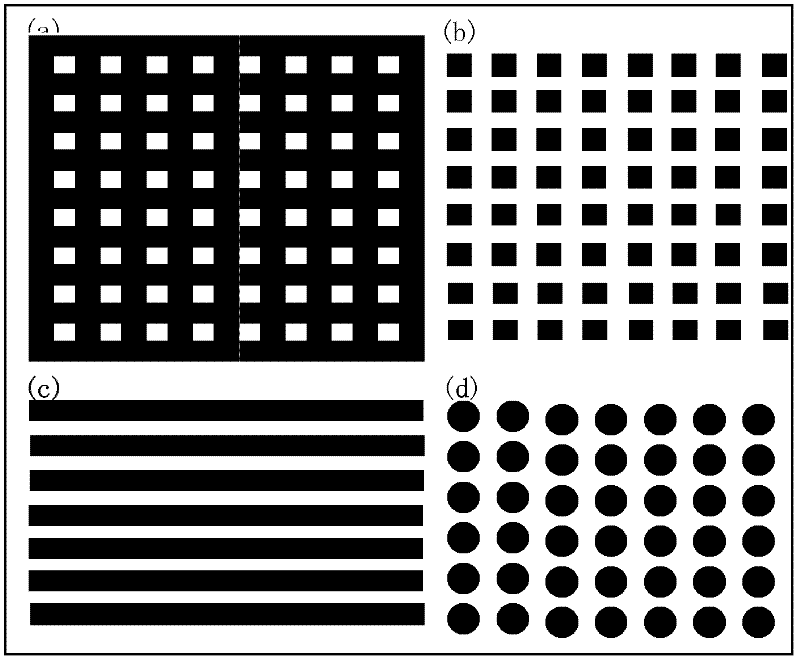

[0031] 1) First, use photolithography technology to lithographically pattern the designed patterns of various micron-scale specifications (such as figure 1 shown), transferred to a photosensitive adhesive-coated fluorinated conductive glass (FTO) or metal titanium substrate, and etched to obtain a pattern consistent with the mask.

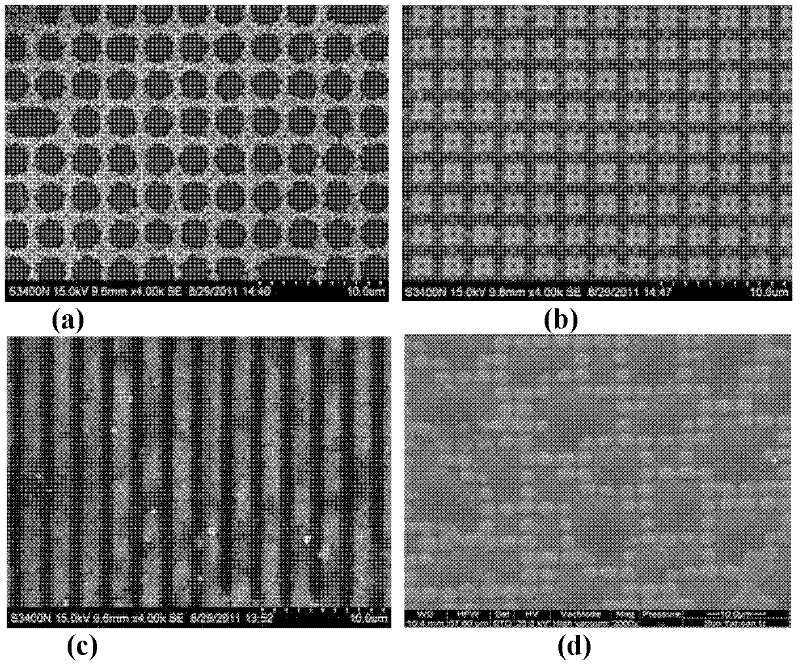

[0032] 2) Next, put the above-mentioned patterned FTO or metal titanium substrate into the reaction kettle, and grow titanium dioxide nano-arrays by hydrothermal synthesis. The array as a whole presents a micro-nano pattern structure, showing microphase separation, and its hydrophilicity and hydrophobicity change greatly, and it is also easy to attach to amorphous carbon. Due to TiO 2 Nanowires can only be selectively grown in micron-scale pattern areas, and TiO cannot be grown in areas withou...

Embodiment 1

[0041] Preparation of micro-nanoscale patterns by photolithography

[0042] By formulating a set of mask templates with pattern specifications ( figure 1 (a)~ figure 1 As shown in (d), such as: a dot matrix pattern with a diameter and pitch of 1 micron, a line width: a parallel line array pattern with a pitch of 1:1.5 microns, a dot matrix pattern of 0.5 micron×1 micron, or their inversion picture. The pattern of the mask plate is transferred and prepared on the fluorinated conductive glass (FTO) by conventional photolithography technology or screen printing technology, and finally a fluorinated conductive glass FTO substrate pattern corresponding to the pattern of the mask plate is obtained.

Embodiment 2

[0044] Preparation of TiO by Hydrothermal Synthesis 2 Nanowire Array Micro-Nano Pattern Structure

[0045] On the fluorinated conductive glass or titanium metal substrate with micron-scale pattern structure, the hydrothermal synthesis method is used to selectively synthesize TiO in the pattern area 2 nanoarray. TiO with different diameters and different nanowire densities can be prepared by changing the concentration of the reaction solution, reaction temperature, and growth time. 2 Nano-array, the typical process is: butyl titanate 0.5ml (purity 98%), reaction time 0.5 hours, reaction temperature 150°C, hydrochloric acid: deionized water volume ratios are 15 / 25, 18 / 23, 20 / 20 , 23 / 18.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com