Neopentyl glycol oxyalkylation synthetic method

A technology of pentanediol alkane and a synthesis method, applied in the synthesis field of neopentyl glycol alkoxylation, can solve the problems of violent reaction, rapid temperature rise, unfavorable environmental protection of solid impurities, poor cooling effect, etc., and achieves improved selectivity. , The product distribution is reasonable, the effect of less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

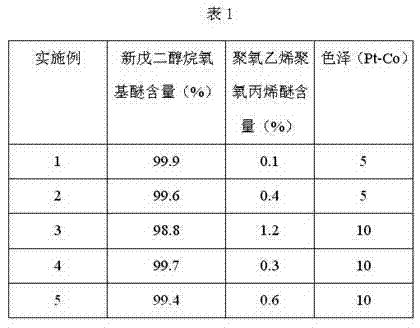

[0024] Add neopentyl glycol 500g in the reactor, solid sodium hydroxide 0.5g, diethylene glycol dimethyl ether 500g vacuumize with vacuum pump, adopt N 2 Replace the air in the reactor. After three replacements, heat up to 80°C under vacuum ≥ -0.05MPa and start adding ethylene oxide continuously. Control the reaction temperature at 80-110°C and the pressure in the reactor at 0.1-0.3Mpa , add 657 g of ethylene oxide, keep warm after adding, and continue the reaction until the pressure no longer drops. After the reaction is completed, vacuum is used to remove the solvent, and the removed solvent is recycled by a condensing device. After the solvent has been removed, cool down to 40-80°C and add 0.5 g of glacial acetic acid to neutralize it, and discharge to obtain neopentyl glycol polyoxyethylene ether. Gas-liquid phase and chromatographic analysis: neopentyl glycol polyoxyethylene ether content 99.9%, by-product polyethylene glycol 0.1%, visually inspected sample color No. 5 (...

Embodiment 2

[0026] Add neopentyl glycol 400g in the reactor, solid potassium hydroxide 1.5g, toluene 600g vacuumize with vacuum pump, adopt N 2 Replace the air in the reactor. After three replacements, heat up to 80°C under vacuum ≥ -0.05MPa and start adding propylene oxide continuously. Control the reaction temperature at 90-130°C and the pressure in the reactor at 0.15-0.35Mpa. Add 1050g of propylene oxide, keep warm after adding and continue the reaction until the pressure no longer drops. After the reaction is completed, vacuum is used to remove the solvent, and the removed solvent is recycled by a condensing device. After the solvent has been removed, cool down to 40-80°C and add 1.5 g of glacial acetic acid to neutralize it, and discharge to obtain neopentyl glycol polyoxypropylene ether. Gas phase and liquid chromatography analysis: the content of neopentyl glycol polyoxypropylene ether is 99.6%, the by-product polypropylene glycol is 0.4%, and the color of the sample is No. 5 (Pt...

Embodiment 3

[0028] In the reactor, add neopentyl glycol 50g, solid sodium methylate 1.4g, xylene 200g vacuumize with vacuum pump, adopt N 2 Replace the air in the reactor. After three replacements, heat up to 80°C under vacuum ≥ -0.05MPa and start adding ethylene oxide continuously. Control the reaction temperature at 90-170°C and the pressure in the reactor at 0.15-0.60Mpa , add 1314g of ethylene oxide, keep warm after adding and continue the reaction until the pressure no longer drops. After the reaction is completed, vacuum is used to remove the solvent, and the removed solvent is recycled by a condensing device. After the solvent has been removed, cool down to 40-80°C and add 1.4g of glacial acetic acid to neutralize it, and discharge to obtain neopentyl glycol polyoxyethylene ether. Gas phase and liquid chromatography analysis: the content of neopentyl glycol polyoxyethylene ether is 98.9%, the by-product polyethylene glycol is 1.1%, and the color of the sample is No. 10 (Pt-Co unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com