Stachyose infant nourishing cereal and its preparation method

A technology of nutritional rice flour and stachyose, which is applied to the field of nutritional rice flour for infants and young children with stachyose and its preparation, and can solve the problems of lack of immunoglobulin, unreasonable formula, and difficulty in being digested.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

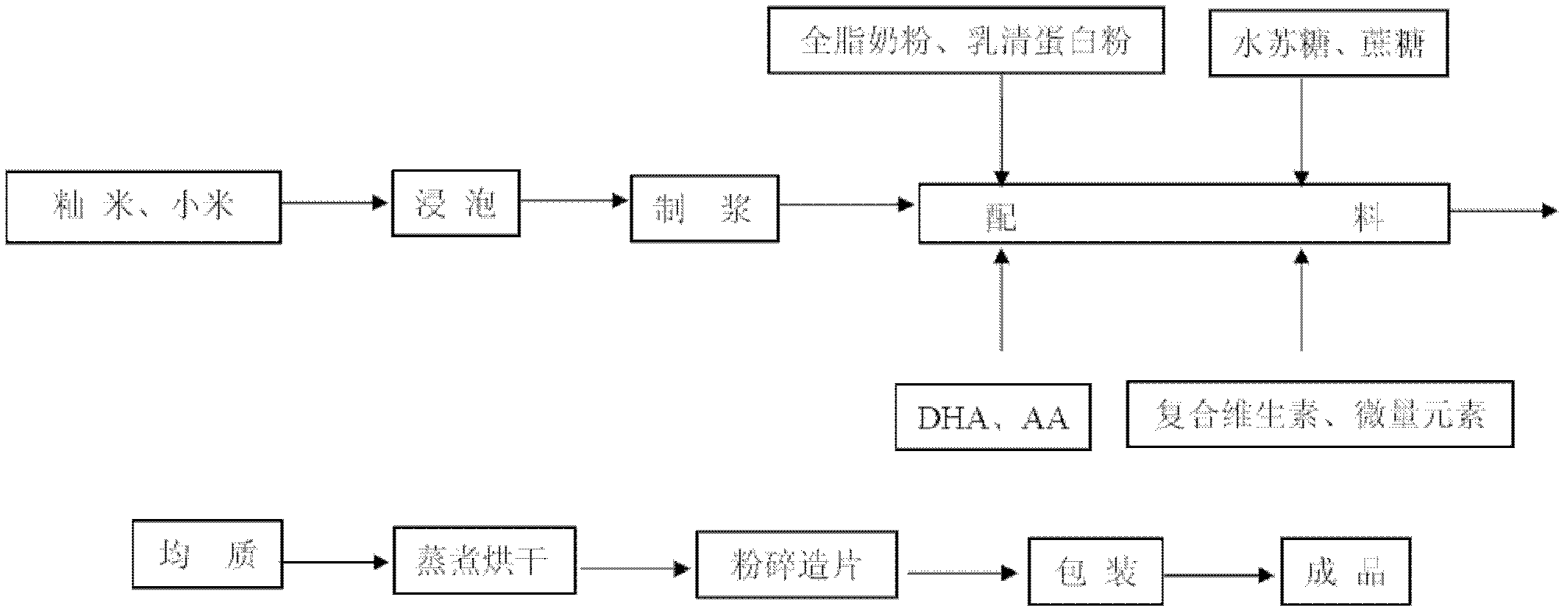

[0054] In another aspect, the present invention provides a method for preparing the stachyose nutritional rice flour for infants and young children, which includes the steps of pulping, batching, cooking and drying, crushing and tableting, and optionally packaging. Specifically, the preparation method of the present invention comprises the following preparation steps:

[0055] (1) Pulping: Wash the indica rice and millet, soak for 1-2 hours, the ratio of indica rice and millet to water is 9-11:1, and beat the soaked indica rice;

[0056] (2) Ingredients: Weigh other raw material components according to the weight ratio, mix with the rice milk resulting from step (1), and then homogenize for 18 to 25 minutes;

[0057] (3) Cooking and drying: use steam drum drying to cook, press and dry to form flakes, the steam pressure is between 0.2 and 0.3Mpa, and the moisture content of the rice flour flakes after drying is not higher than 6.0%;

[0058] (4) Pulverizing and making flakes: ...

Embodiment 1

[0072] Take 85 kg of high-quality indica rice and 6 kg of millet, wash them clean, soak them in 910 kg of water for 1 hour, and beat them, then add 4.0 kg of whole milk powder, 2.5 kg of whey protein powder, 2 kg of stachyose, 10.0 kg of sucrose, and enoic acid 295g, arachidonic acid 109g, vitamin A acetate 0.0006kg, cholecalciferol 0.000009kg, thiamine nitrate 0.0008kg, riboflavin 0.0006kg, nicotinamide 0.0054kg, calcium carbonate 0.3kg, calcium hydrogen phosphate 1.2 kg, 0.0080kg of iron pyrophosphate, 0.0045kg of zinc sulfate, and 0.00003kg of potassium iodide were mixed with the prepared rice slurry and homogenized for 22 minutes. Then, the slurry is pumped into a steam drum dryer with a screw pump to cook, press and dry to form flakes, the steam pressure is controlled between 0.2-0.3Mpa, and the moisture content of the dried rice flour flakes is not higher than 6.0%. The dried rice noodle flakes are crushed into fine flakes, and aseptically packaged to obtain a finished p...

Embodiment 2

[0074] according to figure 1 Shown technological process, the preparation steps of stachyose nutritional rice flour for infants and young children of the present invention are as follows:

[0075] Take 82kg of high-quality indica rice and 8kg of millet, wash them clean, soak them in 960kg of water for 1 hour, and beat them, then add 4.3kg of whole milk powder, 2.0kg of whey protein powder, 3kg of stachyose, 11.0kg of sucrose, and enoic acid 290g, arachidonic acid 106g, vitamin A acetate 0.0007kg, cholecalciferol 0.00001kg, thiamine nitrate 0.00085kg, riboflavin 0.00065kg, nicotinamide 0.005kg, calcium carbonate 0.32kg, calcium hydrogen phosphate 1.5 kg, 0.009kg of iron pyrophosphate, 0.0048kg of zinc sulfate, and 0.000034kg of potassium iodide were mixed with the prepared rice slurry and homogenized for 20 minutes. Then, the slurry is pumped into a steam drum dryer with a screw pump to cook, press and dry to form flakes, the steam pressure is controlled between 0.2-0.3Mpa, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com