Polyarylether compound containing quaternary ammonium salt side group and fluorenyl and preparation method and application thereof

A technology of polyarylether and quaternary ammonium salt, which is applied in the field of polyarylether compound and its preparation, can solve the problems of many side reactions and the inability to accurately control the quantity and position of quaternary ammonium salt, and achieve low preparation cost and high electrolyte permeability Low, excellent chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

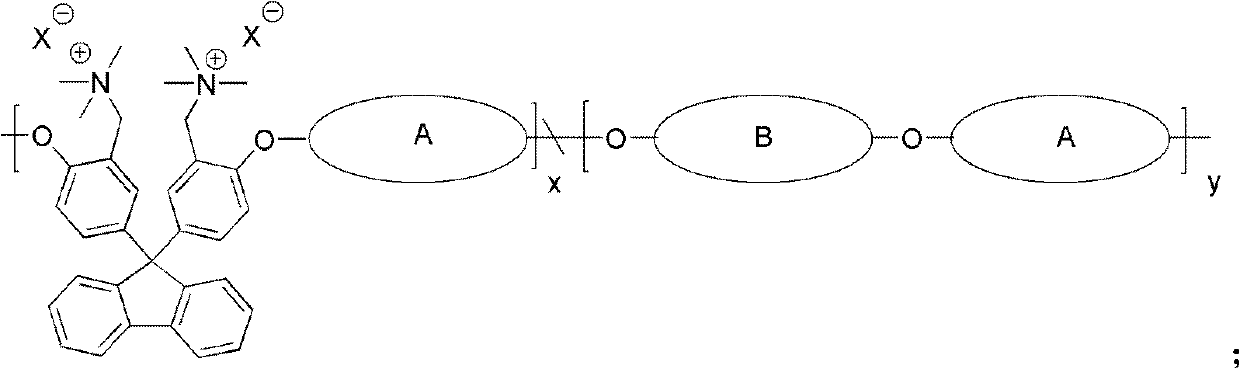

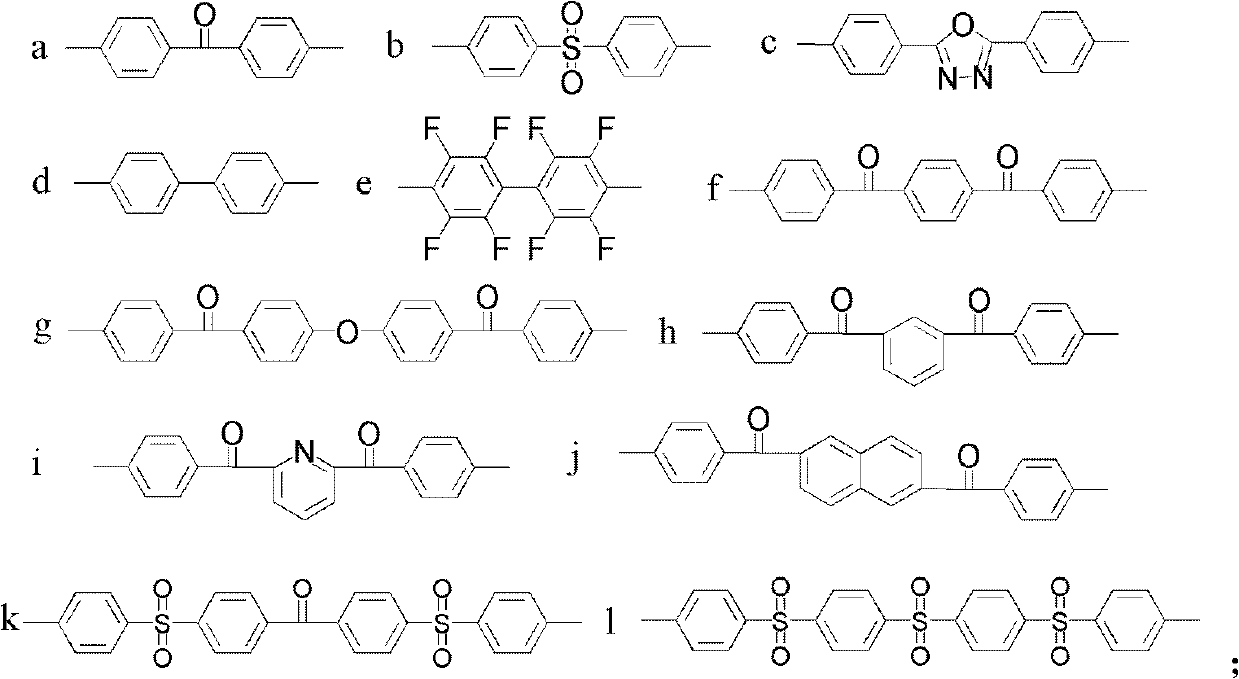

[0052] The synthesis of embodiment 1~5 polyarylene ether compound eII-OH-x

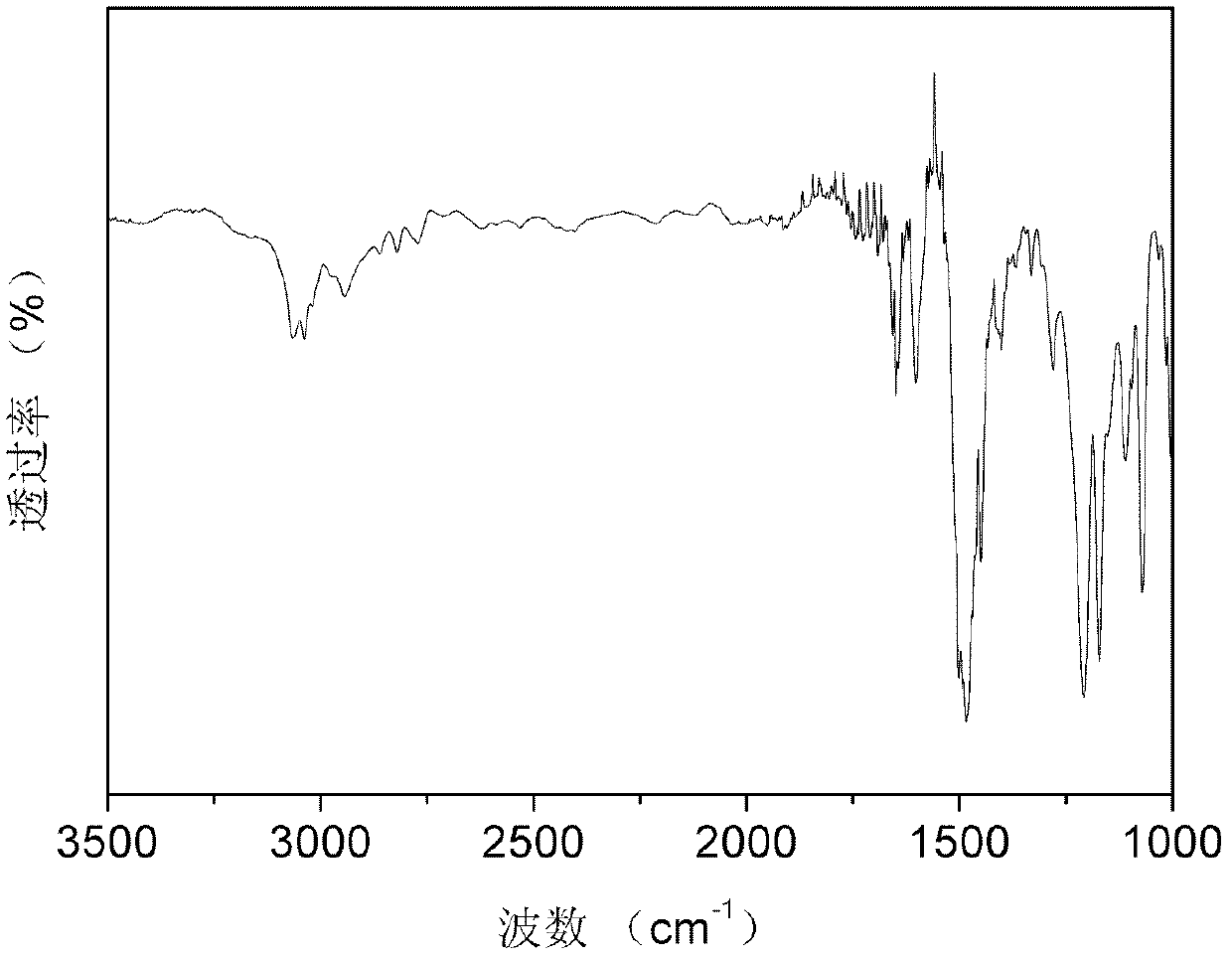

[0053] The bisphenol monomer containing the tertiary amine side group, the bisphenol monomer II and the aromatic monomer e containing the halogen atom are added in the three-necked flask of 25ml according to the charging amount shown in table 1, add 5ml dimethyl sulfoxide as Solvent, add 0.4887g cesium carbonate as a catalyst, and react at 80°C for 24h under the protection of nitrogen. The product was precipitated in water, after drying, dissolved in 20ml N,N-dimethylacetamide, added 0.7g iodomethane, reacted at room temperature for 24h, poured into 1M sodium hydroxide aqueous solution, soaked for 5 hours, filtered, Dry to obtain the product. Infrared spectrum of polyarylether compound eII-OH-100 see figure 1 . figure 1 Medium, 3038cm -1 The peaks at 2943 and 2820cm are the stretching vibration peaks of the C-H bond on the benzene ring -1 The peak at is the stretching vibration peak of methyl and...

Embodiment 6~10

[0057] The synthesis of embodiment 6~10 polyarylene ether compound aI-Cl-x

[0058]The bisphenol monomer containing the tertiary amine side group, the bisphenol monomer I and the aromatic monomer a containing the halogen atom are added in the three-necked flask of 25ml by the charging amount shown in table 2, add 5ml dimethyl sulfoxide as Solvent, add 0.4887g cesium carbonate as a catalyst, and react at 80°C for 24h under the protection of nitrogen. The product was precipitated in water, after drying, dissolved in 20ml N,N-dimethylacetamide, added 0.7g iodomethane, reacted at room temperature for 24h, poured into 1M sodium chloride aqueous solution, soaked for 5 hours, filtered, Dry to obtain the product.

[0059] Table 2 Reaction parameters and results of polyarylether compound aI-Cl-x

[0060]

Embodiment 11~15

[0061] Examples 11-15 Preparation of ion-exchange membranes based on eII-OH-x materials and their application in all-vanadium redox flow batteries

[0062] Weigh 1g of polyarylether compound eII-OH-x, dissolve it in 5ml of dimethyl sulfoxide, cast it on a glass plate placed horizontally beforehand, and dry it at 80°C in a dust-free environment to prepare the corresponding ion exchange membrane ; Use the proton exchange membrane to assemble a single cell of an all-vanadium redox flow battery, and measure its resistance to VO 2+ penetration performance. The experimental performance parameters are shown in Table 3.

[0063] Table 3 Performance parameters of ion-exchange membranes based on eII-OH-x materials

[0064]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com