Hydrophobically associating polymer, preparation method and application thereof

A polymer and hydrophobic monomer technology, applied in the field of functional polymers, can solve the problems of difficult diffusion of polymerization heat, local overheating, uneven polymerization reaction, etc., achieve good solubility and viscosity-increasing performance, simple synthesis process, reproducible good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

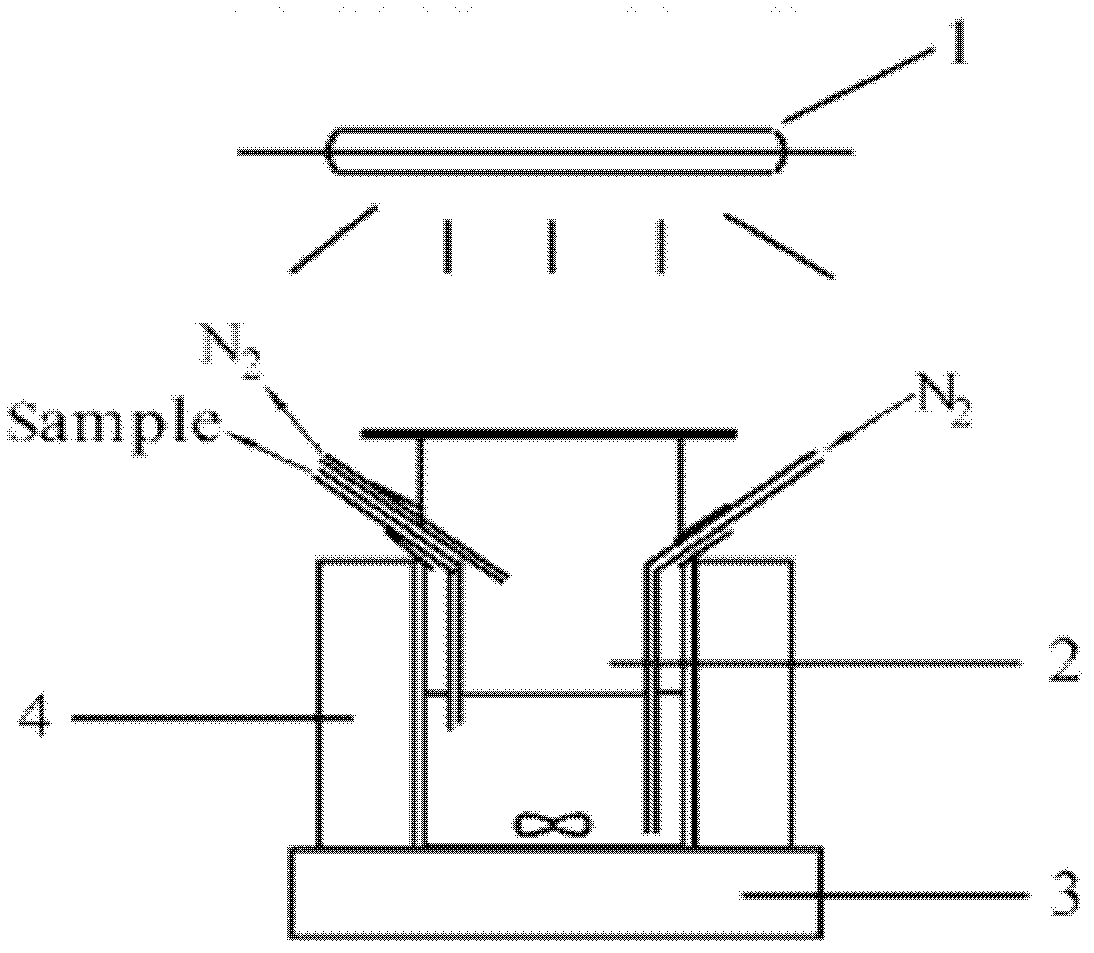

Method used

Image

Examples

Embodiment 1

[0032] Example 1, AM / NaAA / C 16 Synthesis of DMAAC Hydrophobically Associating Terpolymer

[0033] Preparation of 30% sodium acrylate aqueous solution: A. Dissolve 72g of acrylic acid in 100g of deionized water; B. Dissolve 40g of sodium hydroxide in 101.33g of deionized water; The sodium solution was mixed to obtain a 30% NaAA solution;

[0034] 10% cetyl allyl dimethyl ammonium chloride (C 16 DMAAC) solution preparation: take by weighing 10g cetyl allyl dimethyl ammonium chloride and be dissolved in 90g water, obtain 10% cetyl allyl dimethyl ammonium chloride (C 16 DMAAC) solution;

[0035] Weigh 349.507g of deionized water into the reaction vessel, add 47.000g of 30% sodium acrylate solution, 17.275g of 10% hexadecyl allyl dimethyl ammonium chloride solution, 59.995g of acrylamide, ethylenediaminetetra Disodium acetate 0.076g, photoinitiator 1-[4-(2-hydroxyethoxy)-phenyl]-2-hydroxy-2-methylacetone 0.038g, after mixing evenly, adjust the pH value to the range of 11-12 In...

Embodiment 2

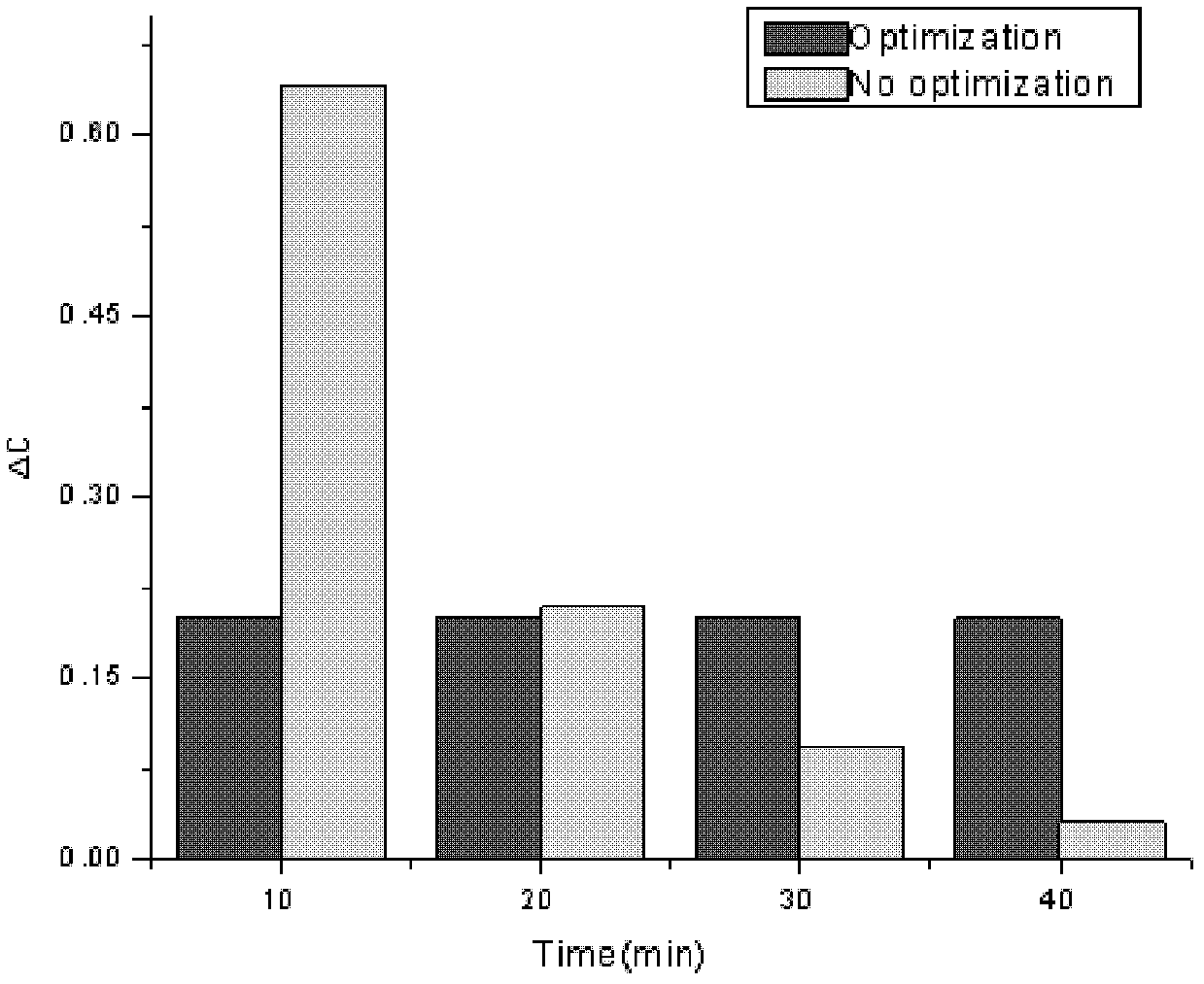

[0041] Embodiment 2, the impact of light time on properties such as polymer viscosity shown in formula I

[0042] By adjusting the light time to achieve a certain amount of decomposition of the photoinitiator within each period, the polymerization process was divided into four stages. In the test, the total time of the light time and the light-off time in each stage was set to 10 minutes, and the light intervals were: 2.5 minutes of light, 7.5 minutes of cut-off; 3 minutes of light, 7 minutes of cut-off; 4 minutes of light, 6 minutes of cut-off; 3min, the photoinitiator decomposition amount changes with time in each period as follows figure 2 As shown, after adjusting the light mode, the decomposition amount of the photoinitiator is constant every 10 minutes. The monomer concentration is 10%, and other reaction conditions are consistent with those in Example 1. After polymerization, the polymer shown in formula I is obtained, and its viscosity test is carried out. The result...

Embodiment 3

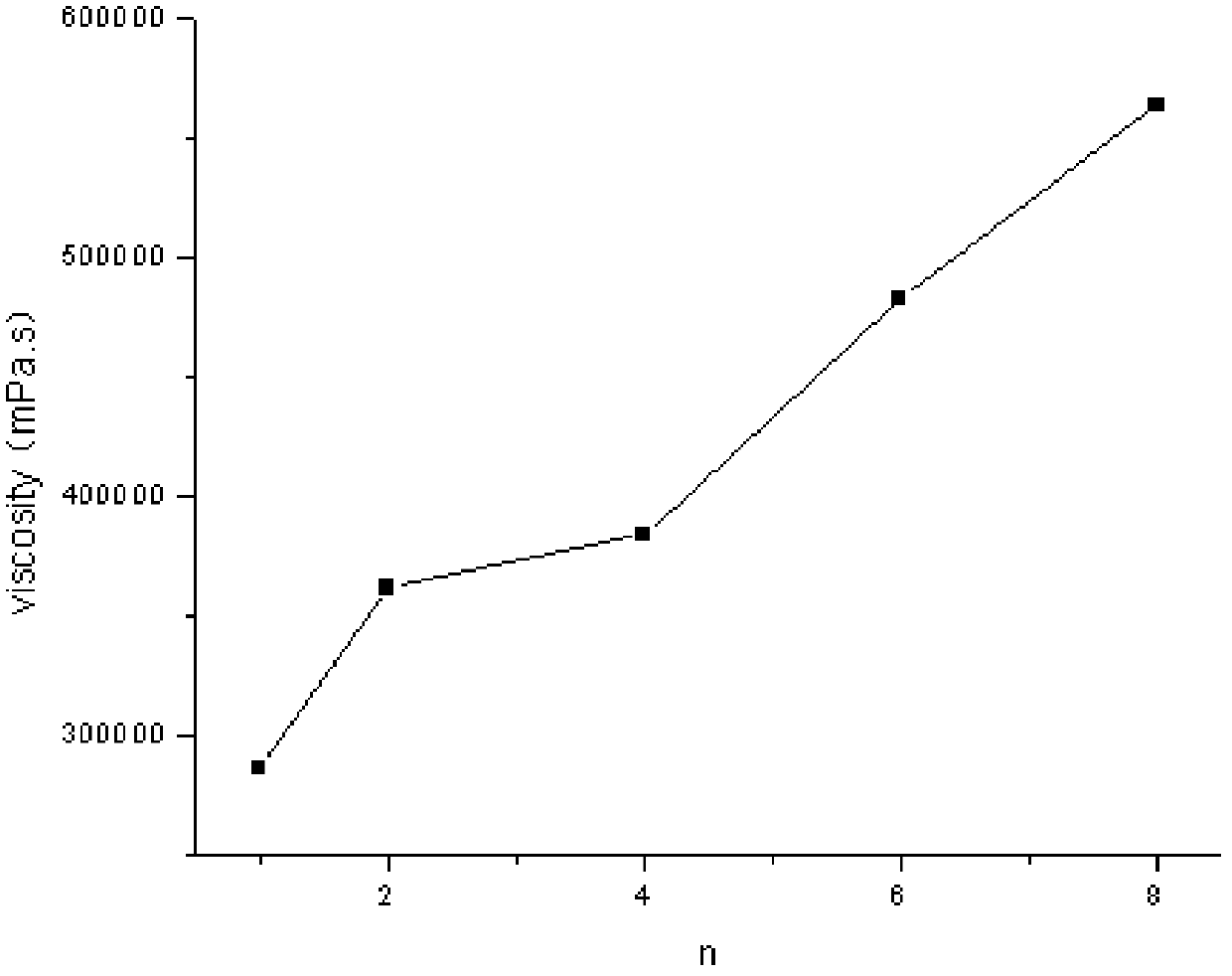

[0043] Embodiment 3, the influence of light intensity on properties such as polymer viscosity shown in formula I

[0044] The light intensity was changed by changing the effective passage area of ultraviolet light, and the fixed light time was 40 minutes. Two optimization methods were adopted, as shown in Table 1, the monomer concentration was 10%, and other reaction conditions were exactly the same as in Example 1. The photoinitiator decomposition trend is as follows Figure 4 As shown, using exponential optimization, the decomposition amount of photoinitiator per unit time is a certain value. Viscosity test was carried out after polymerization, and the result was: the viscosity of the polymer obtained by direct polymerization without changing the light intensity was 286.7 Pa s, the viscosity of the polymer obtained by optimization method 1 was 353.9 Pa s, and the viscosity of the polymer obtained by optimization method 2 was 445.0 Pa·s. When the number of light intensity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com