Flame-retardant polyamide composite material and preparation method thereof

A technology of flame-retardant polyamide and composite materials, which is applied in the field of flame-retardant polyamide composite materials, can solve the problems of the influence of physical and mechanical properties of materials, the limitation of strong corrosiveness on wide application, the influence of mechanical properties, etc., so as to expand the scope of use and application fields , Excellent non-combustibility, high oxygen index effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

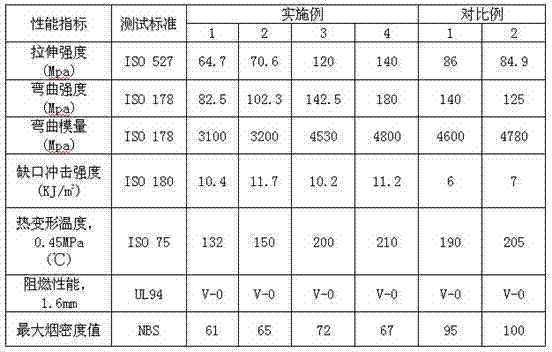

Examples

Embodiment 1

[0031] Put 68 kg of PA6, 25 kg of phenoxy polyphosphazene, 2 kg of magnesium oxide, 3 kg of XB-1000, 0.6 kg of Irganox 168, 0.8 kg of zinc stearate, 0.6 kg of Irganox 1010 in an aspect ratio of 38:1 Melt, mix and disperse in a twin-screw extruder at an extrusion temperature of 220°C for extrusion and granulation.

[0032]

Embodiment 2

[0034] Put 68 kg of PA66, 25 kg of phenoxy polyphosphazene, 2 kg of magnesium oxide, 3 kg of XB-1000, 0.6 kg of Irganox 168, 0.8 kg of zinc stearate, 0.6 kg of Irganox 1010 in an aspect ratio of 38:1 Melting, mixing and dispersing in a twin-screw extruder, the extrusion temperature is 230°C, extrusion granulation.

[0035]

Embodiment 3

[0037] 50 kg of PA6, 15 kg of glass fiber, 5 kg of talc, 20 kg of N-(dichlorophosphoryl) trichlorophosphazene, 4 kg of aluminum hydroxide, 4 kg of XB-1000, 0.6 kg of Irganox 1010, 0.8 kg of hard Zinc fatty acid and 0.6 kg of Irganox 1098 were melt-mixed and dispersed in a twin-screw extruder with an aspect ratio of 38:1, and the extrusion temperature was 220° C. to extrude and granulate.

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com