Microalgae cultivation method and device for controlling nutritive salt replenishment on basis of pH feedback

A feedback control and nutrient salt technology, applied in the field of microalgae cultivation, can solve problems such as low yield and affecting production control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] The microalgal species used is Spirulina platensis (Spirulina platensis, 439, freshwater algae species bank of the Typical Culture Collection Committee of the Chinese Academy of Sciences), and the above-mentioned algae species are used for fed-batch culture based on pH feedback control to add nutrients.

[0071] The composition of culture medium and nutrient salt feeding solution is the same as that of Comparative Example 1.

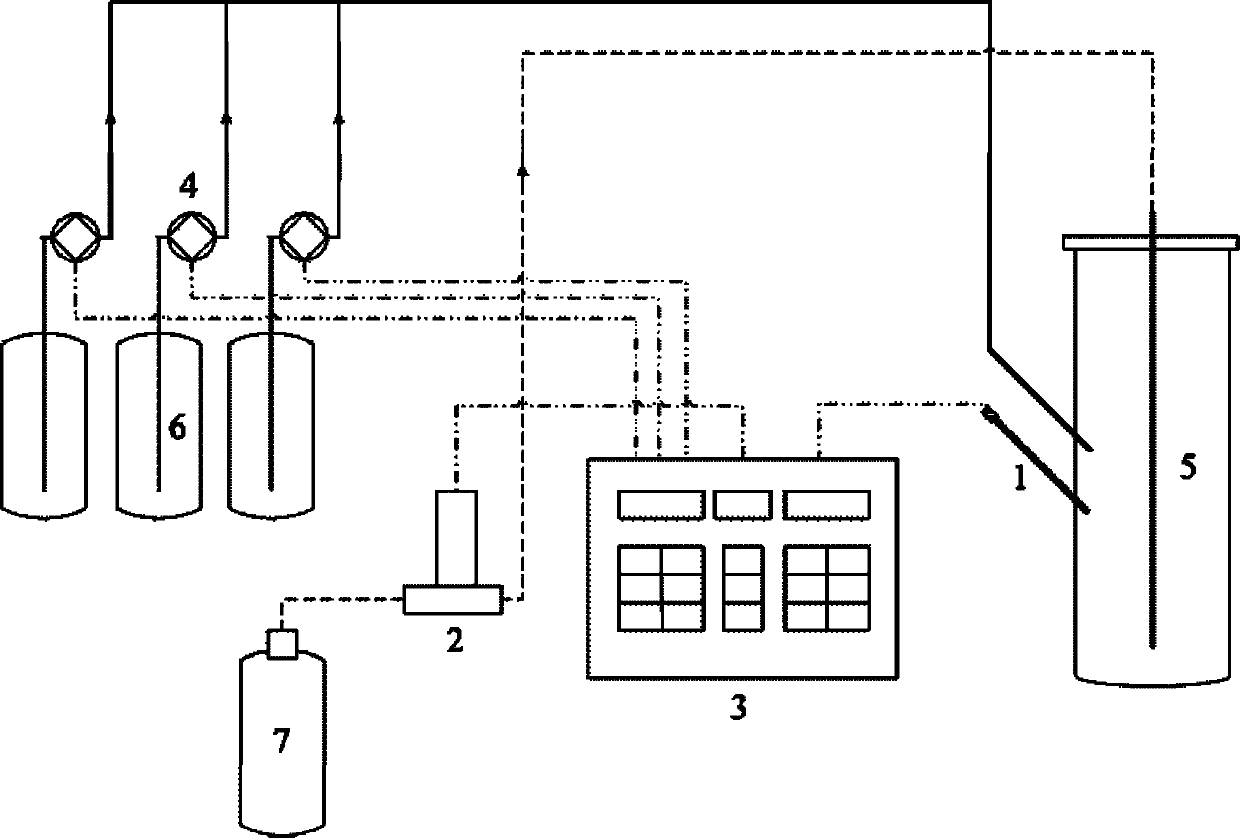

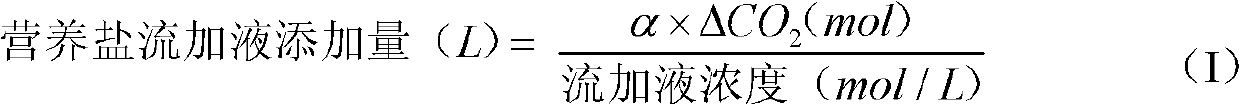

[0072] The microalgae incubator adopts 1000m 2 The open raceway pool uses an impeller stirring device to drive the flow and mixing of the culture solution, and the thickness of the culture solution layer is 15cm. See Nutrient Control Devices figure 1 , wherein the pH sensor is a commercially available online pH sensor (405-DPAS-SC-S8, Mettler-Toledo Instrument Co., Ltd.), CO 2 The flow metering mechanism is commercially available CO 2 Mass flow controller (D07-11C, Beijing Qixing Huachuang Electronics Co., Ltd.), the control mechanism is an aut...

Embodiment 2

[0079] The microalgae used is Spirulina platensis (Spirulina platensis, 439, freshwater algae species bank of Type Culture Collection Committee, Chinese Academy of Sciences). Fed-batch culture with nutrient supplementation based on pH feedback control was carried out with the above-mentioned algae species.

[0080] The composition of the medium is: sodium bicarbonate 8.4g / L, sodium nitrate 0.5g / L, phosphoric acid 0.1g / L, sodium chloride 1.0g / L, potassium chloride 1.0g / L, magnesium sulfate 0.1g / L, Ferrous sulfate heptahydrate 0.01g / L, disodium EDTA 0.08g / L, calcium chloride 0.04g / L. Nutrient salt feeding liquid is the mixed aqueous solution of sodium nitrate, phosphoric acid and magnesium sulfate, and wherein the concentration of sodium nitrate is 5mol / L, and the concentration of phosphoric acid is 0.216mol / L, and the concentration of magnesium sulfate is 0.017mol / L (sodium nitrate, phosphoric acid , the concentration ratio of magnesium sulfate is determined by the ratio of th...

Embodiment 3

[0087] The microalgal species used was Chlorella sp., 1298, freshwater algae species library of the Type Culture Collection Committee of the Chinese Academy of Sciences, and the above-mentioned algae species were used for fed-batch culture based on pH feedback control to supplement nutrients.

[0088] The composition of the medium is: sodium nitrate 0.1g / L, dipotassium hydrogen phosphate 0.04g / L, magnesium sulfate heptahydrate 0.075g / L, calcium chloride dihydrate 0.02g / L, sodium carbonate 0.02g / L, citric acid 0.006g / L, ferric ammonium citrate 0.006g / L, disodium EDTA 0.001g / L. Nutrient salt feeding liquid 1 is 0.25mol / L sodium nitrate.

[0089] The microalgae incubator adopts a pipeline photobioreactor, the diameter of the pipeline is 8cm, the length is 200m, and the actual culture volume is 1m 3 . See Nutrient Control System figure 1 , wherein the pH sensor is a commercially available online pH sensor (GKF-4-a, Shanghai Shendong Biochemical Sensor Factory). CO 2 The flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com