Method for testing content of metal ions on surface of 8-inch silicon polished wafer for insulated gate bipolar transistor (IGBT)

A technology for surface metal and ion content, applied in measuring devices, material analysis through electromagnetic means, instruments, etc., can solve the problems of low light metal elements, not widely used, complicated quantitative calibration operations, etc., and achieve stable recovery rate , reduce the possibility, improve the effect of test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to understand the present invention more clearly, describe the present invention in detail in conjunction with accompanying drawing and embodiment:

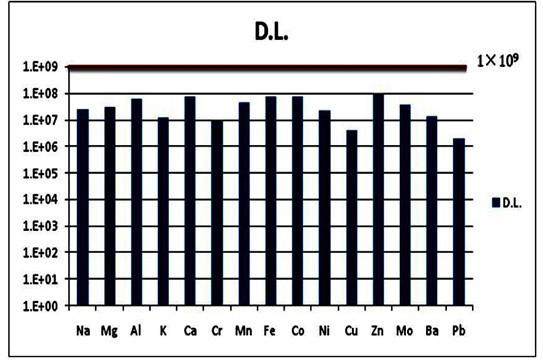

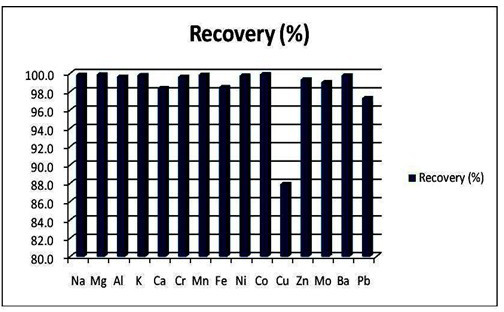

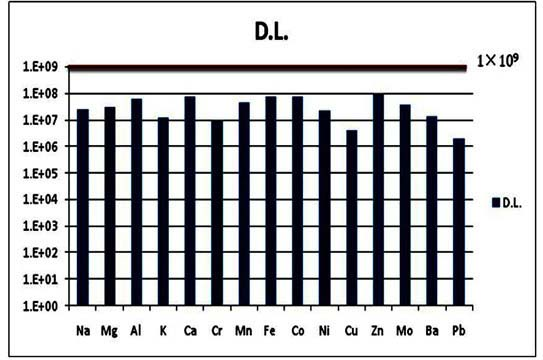

[0036] The invention utilizes full-automatic VPD pretreatment and ICPMS (inductively coupled plasma mass spectrometer) to realize the test of ultra-trace metal ion content on the surface of an 8-inch silicon single crystal polished wafer. Concrete preparation process is as follows:

[0037] 1) The test object used in the experiment is: 8-inch silicon polished wafer, diameter 200mm, thickness 440μm, doped with P crystal orientation, resistivity 5-10Ω; use ADE CR81e to scan after cleaning with SC-1 and SC-2 Particles (0.3um<10), no defects on the surface.

[0038] 2) The reagent specifications used in the experiment are: hydrogen peroxide (H2O2): 35±1%, TAMA AA-10 grade, hydrofluoric acid (HF): 38%, TAMA AA-10 grade; nitric acid (HNO3): 68%, TAMA AA-100 grade; ultrapure water: resistivity ≥ 18M Ω cm, Mill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com