Microporous spongy ondansetron hydrochloride film agent and preparation method thereof

A technology of ondansetron hydrochloride and sponge, which is applied in the direction of non-active ingredient medical preparations, medical preparations containing active ingredients, sheet-like delivery, etc. It can solve the problem of increasing the proportion of plasticizers, unfavorable film formation, Membrane brittle and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

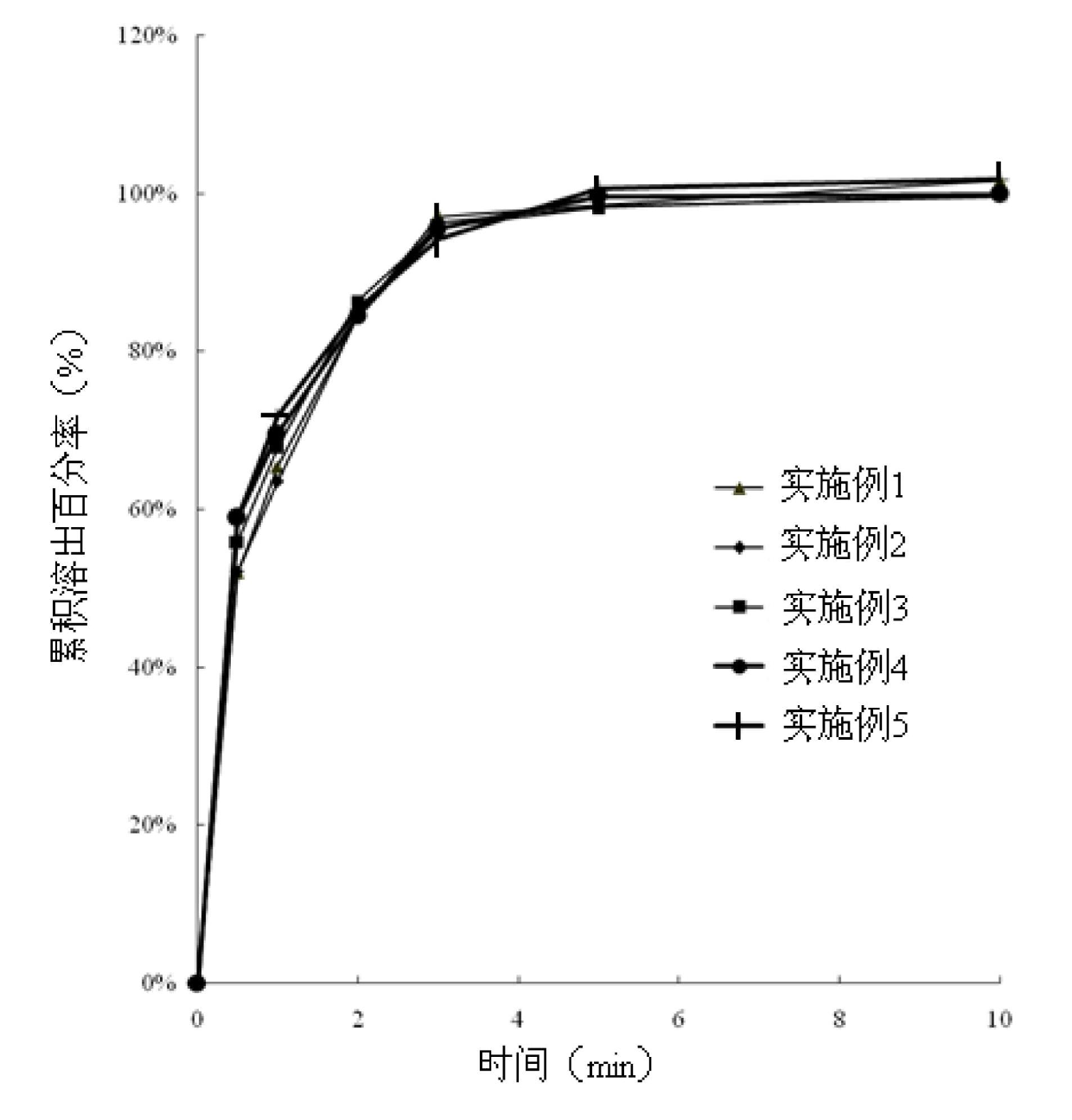

Examples

Embodiment 1

[0060] 80 g of PVA with a molecular weight of 130,000 Daltons and 20 g of HPC with a molecular weight of 600,000 Daltons were dissolved in 500 g of water to form a water slurry.

[0061] Add 100g of pore-forming agent, 10g of ondansetron hydrochloride, 1g of aspartame, 1g of arginine, 5g of glycerin and 3g of titanium dioxide into the above water slurry, stir well and mix evenly.

[0062] The components of the pore-forming agent include chitin with a particle size of 0.5 μm and acetone adsorbed thereon, and the parts by weight of chitin and the parts by weight of the solvent are:

[0063] Chitosan 100 parts

[0064] Acetone 400 parts

[0065] (2) Then use the method reported in the literature of the study of nitroglycerin membranes (Chinese Journal of Pharmaceutical Industry, 1977, 12 (5)) to coat and form membranes to obtain thin film precursors;

[0066] (3) Dry the film precursor obtained in step (2) at 80° C. to obtain the film for the drug film preparation, with a thick...

Embodiment 2

[0074] 16 g of HPMC with a molecular weight of 20,000 Daltons and 64 g of PEO with a molecular weight of 7,000,000 Daltons were dissolved in 500 g of water to form a water slurry.

[0075] Add 200g of pore-forming agent, 50g of ondansetron hydrochloride, 5g of cyclamate and 0.1g of sunset yellow pigment into the above water slurry, fully stir and mix evenly.

[0076] The components of the pore-forming agent include CaCO with a particle size of 50 μm and ethanol adsorbed thereon, and the parts by weight of CaCO and the parts by weight of the solvent are:

[0077] CaCO3 100 parts

[0078] Ethanol 100 parts

[0079] Others are the same as embodiment 1.

[0080] The weight ratio of each component:

[0081] Low molecular weight water-soluble polymer material: high molecular weight water-soluble polymer material=1:4;

[0082] Water-soluble polymer material: water-insoluble micropowder = 1:1.25;

[0083] The diameter of the micropores is 10 nm.

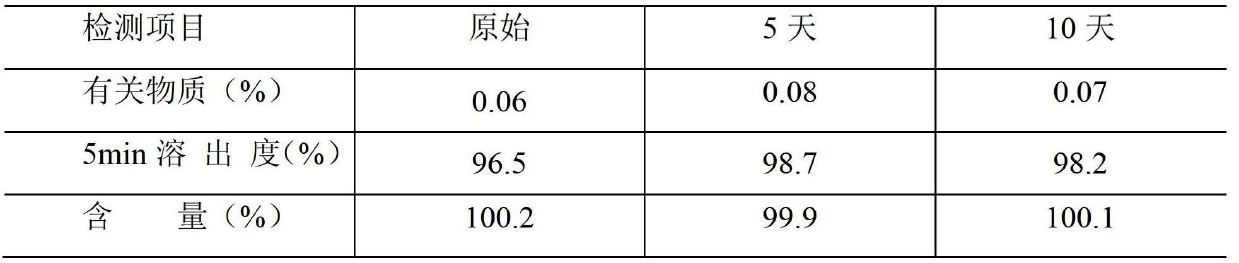

[0084] Performance evaluation: ...

Embodiment 3

[0086] Dissolve 60 g of sodium alginate with a molecular weight of 32,000 Daltons and 120 g of CMC-Na with a molecular weight of 700,000 Daltons in 700 g of water to form a water slurry.

[0087] Add 90g of pore-forming agent, 50g of ondansetron hydrochloride, 5g of sucralose, 5g of triethyl citrate and 3g of titanium oxide into the above water slurry, fully stir and mix evenly.

[0088] The component of described pore-forming agent comprises the sodium polystyrene sulfonate of 10 μ m and the ethanol adsorbed on it, the parts by weight of sodium polystyrene sulfonate and the parts by weight of solvent are:

[0089] Sodium polystyrene sulfonate 100 parts

[0090] Ethanol 100 parts

[0091] Others are the same as embodiment 1.

[0092] The weight ratio of each component:

[0093] Low molecular weight water-soluble polymer material: high molecular weight water-soluble polymer material=1:2;

[0094] Water-soluble polymer material: water-insoluble micropowder = 1:0.25;

[0095...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap