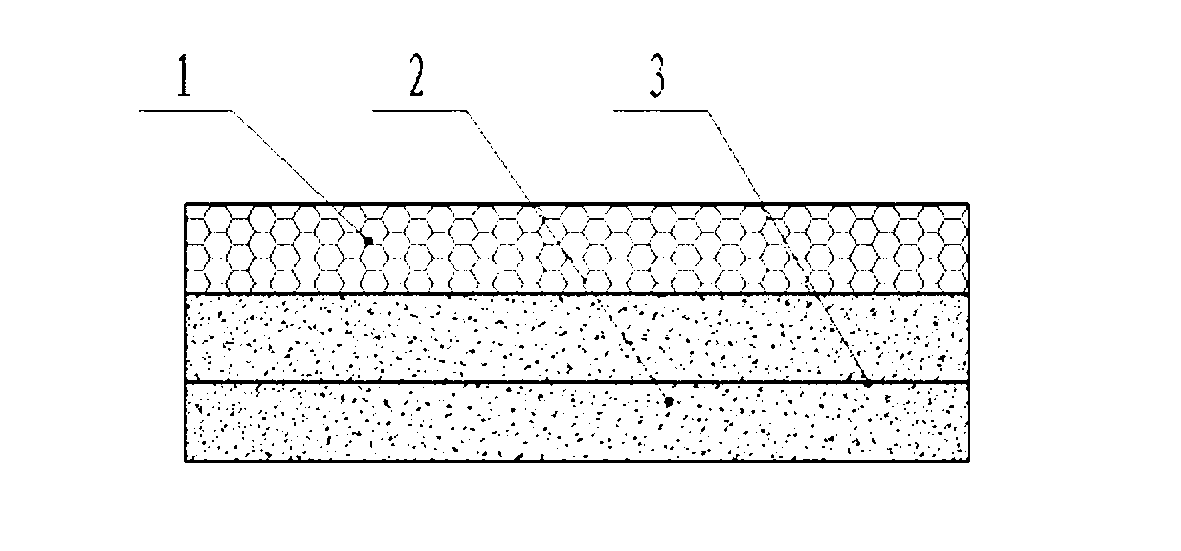

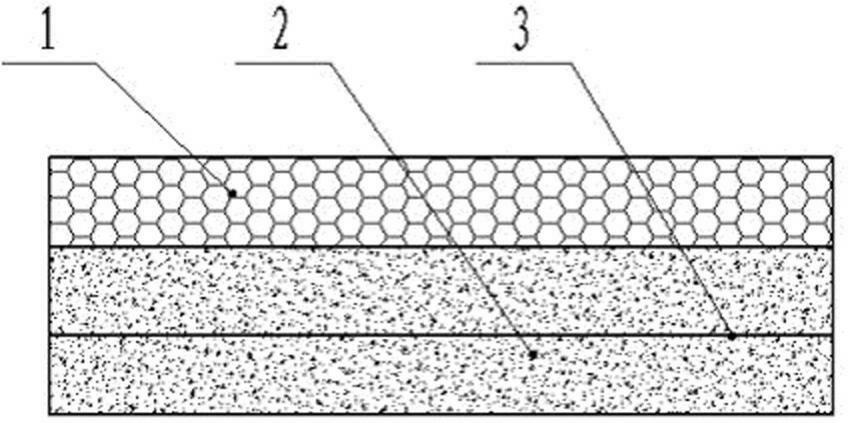

Close packing high-performance cement-based fiber composite product and production method thereof

A fiber composite, high-performance technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., to achieve the effect of improving strength, reducing the use of high energy consumption raw material cement, and reducing the amount of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] 1) Mix 20kg (20%) of cement, 40kg (40%) of sand, 10kg (10%) of glass shavings, 1kg (1%) of PVA fiber, 1kg (1%) of wood fiber, powdered Pigment 3kg (3%), redispersible latex powder 2.5kg (2.5%), water reducing agent naphthalene sulfonate formaldehyde condensate 0.5kg (0.5%), early strength agent sulfate 0.5kg (0.5%), antifreeze agent Stir 0.5kg (0.5%) of calcium chloride, 3kg (3%) of fly ash, 2kg (2%) of mineral powder, and 16kg (16%) of water to make a slurry for later use.

[0075] 2) Make a decorative layer in the mold with the prepared surface mortar by spraying method, and let it solidify naturally for 10 minutes;

[0076] 3) Mix 23kg (23%) of cement, 10kg of water (10%), 44kg of superfine quartz powder (44%), 10kg of metakaolin (10%), 1kg of glass fiber (1%), and 1kg of carbon fiber according to the weight distribution ratio. (1%), PVA fiber 0.5kg (0.5%), pulp fiber 0.5kg (0.5%), silicone modified polypropylene emulsion 4kg (4%), water reducing agent naphthalene s...

Embodiment 2

[0082] 1) Mix 45kg (45%) of cement, 20 kg (20%) of fine stones, 5kg (5%) of ceramic debris, 5kg (5%) of liquid pigment, 2 kg (2%) of polypropylene emulsion, 3kg (3%) of silica fume and 20kg (20%) of water are stirred evenly and made into a slurry for later use.

[0083] 2) Use the brushing method to make a decorative layer in the mold with the prepared surface mortar, and let it cure naturally for 20 minutes;

[0084] 3) Mix 51kg (51%) of cement, 15kg (15%) of water, 25kg (25%) of superfine quartz powder, 4kg (4%) of fly ash, 0.4kg (0.4%) of steel fiber, Silicone modified styrene-acrylic emulsion 0.5kg (0.5%), water reducer sulfonated melamine formaldehyde condensate 0.5kg (0.5%), early strength agent nitrite 0.5kg (0.5%), antifreeze agent potassium carbonate 0.5kg (0.5%), nano-Al 2 o 3 2.6kg (2.6%) of the powder is stirred evenly to make a fiber-reinforced close-packed high-performance cement-based structural layer slurry;

[0085] 4) Vibrationally pour the configured fib...

Embodiment 3

[0089] 1) Mix 23kg (23%) of cement, 40kg (40%) of sand, 20kg (20%) of metal debris, 0.5kg (0.5%) of PU fiber, 0.5kg (0.5%) of pulp fiber, 0.5kg (0.5%) of water reducing agent sulfonated melamine formaldehyde condensate, 0.3kg (0.3%) of early strength agent nitrite, 0.2kg (0.2%) of antifreeze potassium carbonate and 15kg (15%) of water are mixed evenly Make slurry for later use.

[0090] 2) Make a decorative layer in the mold with the prepared surface mortar by laying vibration method, and let it cure naturally for 30 minutes;

[0091] 3) Mix 42kg (42%) of cement, 13kg (13%) of water, 33kg (33%) of superfine quartz powder, 6kg (6%) of mineral powder, 1kg (1%) of basalt fiber, and PU fiber according to the distribution ratio of weight percentage. 0.5kg (0.5%), siloxane modified silicone acrylic emulsion 2.5kg (2.5%), nano-SiO with a solid content of 25% 2 2kg (2%) of the colloid is stirred evenly to make a fiber-reinforced close-packed high-performance cement-based structural ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Impact | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com