Manufacturing method of high-efficiency nano antenna solar battery

A technology for solar cells and nano-antennas, which is applied in circuits, electrical components, and final product manufacturing, etc., can solve the problems of time-consuming and energy-consuming, multi-silicon semiconductor layers, and inability to save silicon materials, and achieve the effect of simplifying the process and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

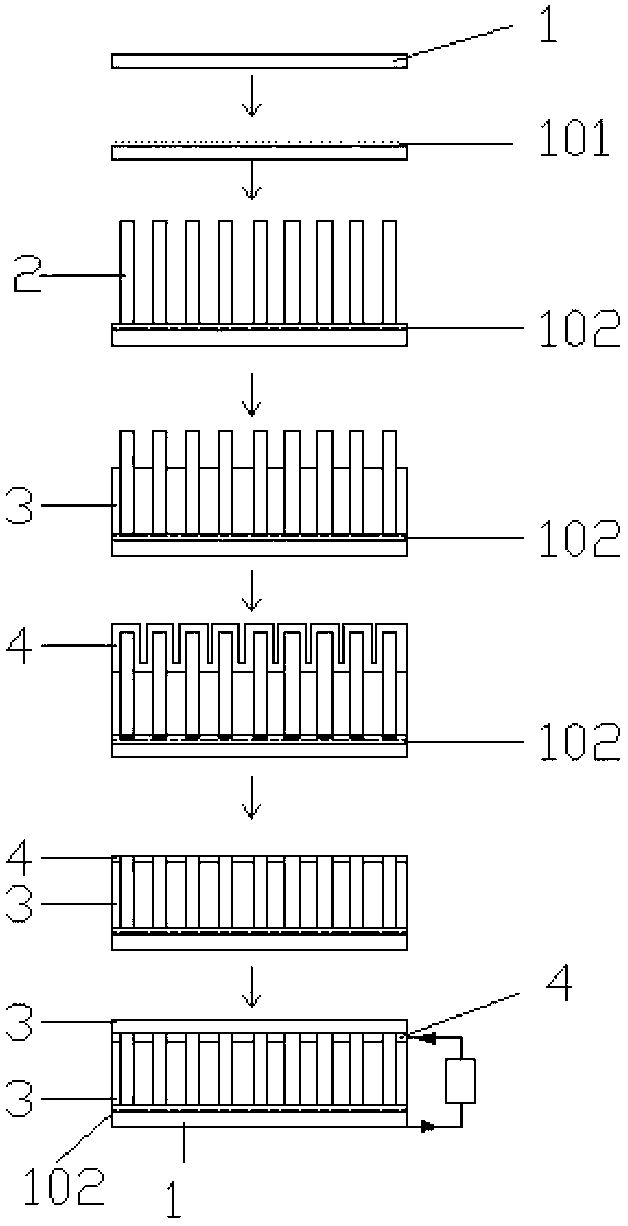

[0028] A) Metal substrate modification

[0029] Such as figure 1 As shown, a copper foil 1 with a size of 50x50mm is selected as the substrate. According to the mass volume ratio of nano-silicon (g): anhydrous ethanol (ml) ratio of 1:200, prepare a nano-silicon cloud solution with a diameter of 70nm, and ultrasonically disperse it evenly for 1 hour. Select high-frequency, 25°C conditions for ultrasound. The treated nano-silicon solution is spin-coated on the copper foil 1 . During spin coating, use a low speed of 200r / min for 10 seconds, and a high speed of 1500r / min for 10 seconds.

[0030] B) Fabrication of battery device sheet

[0031] The graphene-silicon mixture 102 and carbon nanotubes 2 are grown by chemical vapor deposition at a temperature of 800° C. and a standard pressure of 40 Pa, using ethanol as a carbon source. During the whole process, hydrogen gas is used as reducing agent with a flow rate of 50 sccm. Growth was performed using a vacuum tube furnace.

...

Embodiment 2

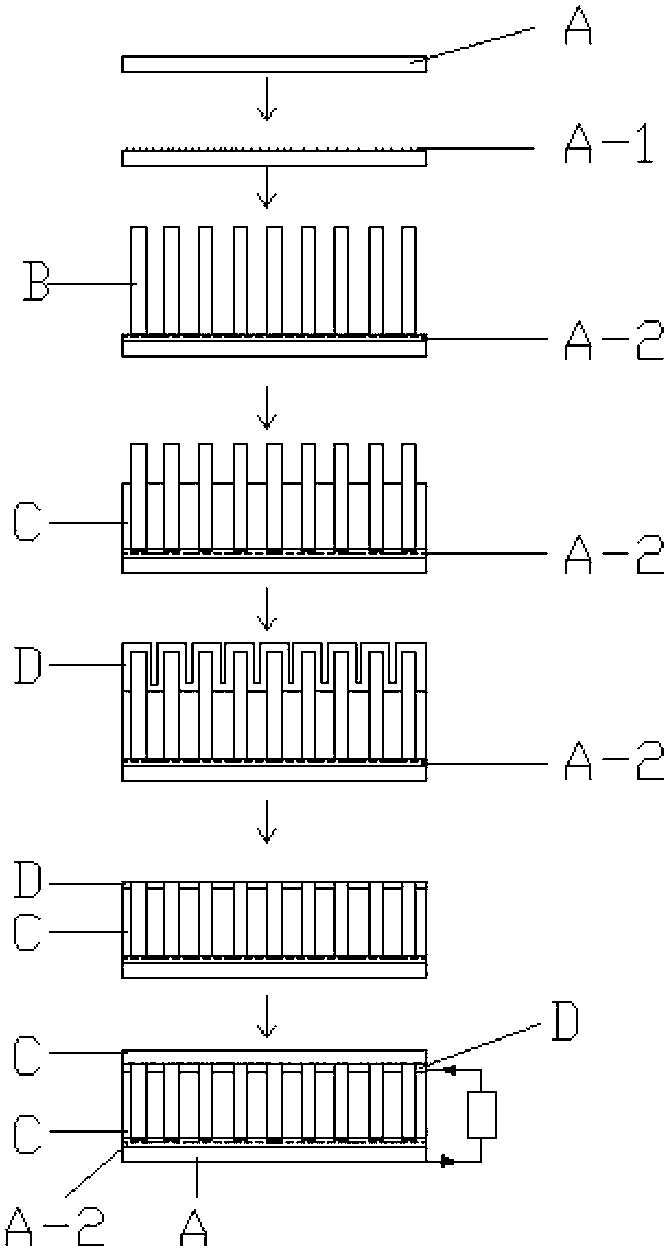

[0039] A) Metal substrate modification

[0040] According to the mass volume ratio of nano-silicon (g): anhydrous ethanol (ml) ratio of 1:200, prepare a nano-silicon cloud solution with a diameter of 30nm, and ultrasonically disperse it evenly for 1 hour. Nickel foil A is selected as the metal substrate, and nano-silica powder A-1 particles with a particle size of 30nm are modified on the surface of the nickel foil by dipping-pulling method.

[0041] B) Fabrication of battery device sheet

[0042] Using acetylene as the carbon source gas, graphene-silicon mixture A-2 and carbon nanotubes B were grown by plasma-enhanced chemical vapor deposition at 850°C and 100 Pa standard pressure. During the whole process, hydrogen gas is used as reducing agent with a flow rate of 50 sccm.

[0043] C) Passivation layer fabrication

[0044] A silicon dioxide passivation layer C is formed between the generated carbon nanotubes B by magnetron sputtering.

[0045] D) Window layer production ...

Embodiment 3

[0050] The concrete steps of this embodiment are identical with embodiment 1, and difference is:

[0051] A) Choose iron foil as the metal substrate. Acetone was chosen as the organic solvent. According to the mass-volume ratio of nano-silicon (g): acetone (ml) ratio of 1:200, configure a nano-silicon turbid solution with a diameter of 50nm.

[0052] B) When the cell device is fabricated, the conditions are: methane as the carbon source, at a temperature of 950°C, and a standard pressure of 60Pa

[0053] C) The finally obtained solar cell uses the iron foil substrate as the back electrode, and the upper ZnO transparent conductive film as the front electrode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com