Preparation method of modified polyurethane pervaporation phenol/water separation membrane

A technology of pervaporation and polyurethane is applied in the field of preparation of modified polyurethane membranes, which can solve the problems of difficult phenol-containing wastewater treatment, low permeation flux, low flux, etc., and achieves good comprehensive separation performance, low cost, and regular arrangement. orderly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

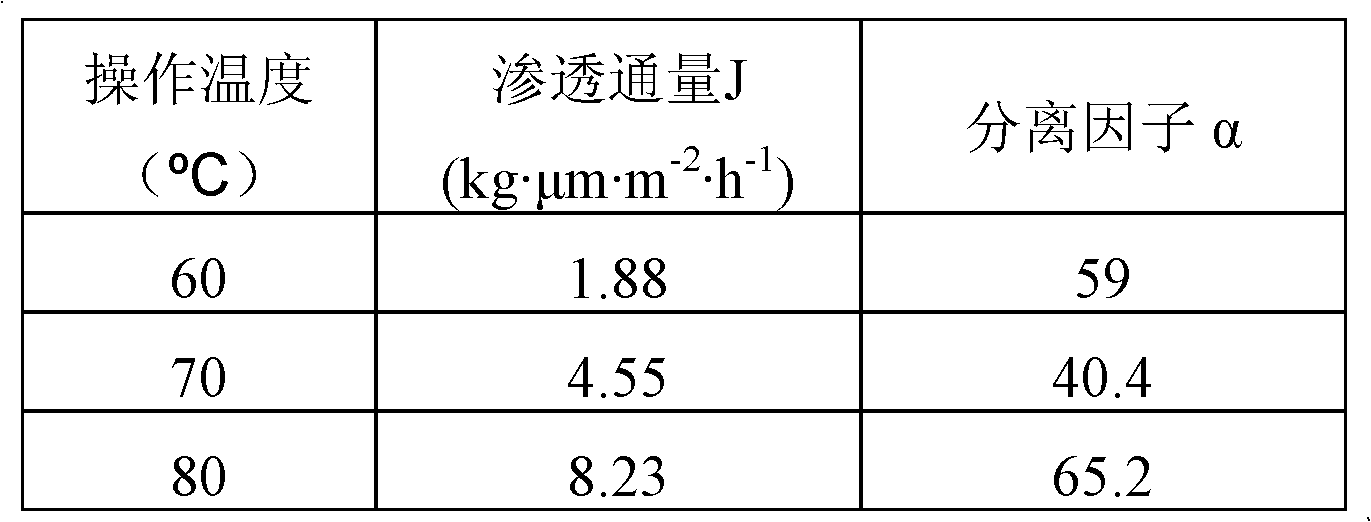

Embodiment 1

[0029] 1) Synthesis of modified polyurethane

[0030]Add 10.9 g of hydroxyl-terminated polybutadiene (the number-average molecular weight is 2500 g / mol, dehydrated under reduced pressure at 110°C before use) and 10 ml of N, N -Dimethylacetamide (purified by vacuum distillation before use), after the two form a homogeneous solution under stirring, then 1.59 g of toluene diisocyanate monomer (the number of moles is twice the number of moles of hydroxyl-terminated polybutadiene) ) and catalyst dibutyltin dilaurate 0.02g (the mass is 0.2% of the mass of hydroxyl-terminated polybutadiene) were added to the above solution, and it was reacted for 1 hour under the conditions of vigorous stirring and heating in a water bath at 30°C to obtain diisocyanate-terminated Prepolymer; then 0.44g 4,4'-diaminodiphenylmethane (0.5 times the mole number of hydroxyl-terminated polybutadiene) and 0.7g β-cyclodextrin (due to β-cyclodextrin The molecular weight of the hydroxyl-terminated polybutadien...

Embodiment 2

[0037] 1) Synthesis of modified polyurethane prepolymer

[0038] Add 9.62 g of hydroxyl-terminated polybutadiene (the number-average molecular weight is 2000 g / mol, dehydrated under reduced pressure at 110°C before use) and 10 ml of N, N -Dimethylacetamide (purified by vacuum distillation before use), after the two form a homogeneous solution under stirring, then 1.88g of toluene diisocyanate monomer (the number of moles is twice the number of moles of hydroxyl-terminated polybutadiene) ) and catalyst dibutyltin dilaurate 0.02g (the mass is 0.2% of the mass of hydroxyl-terminated polybutadiene) was added to the above solution, and it was reacted for 0.5 hours under the conditions of vigorous stirring and heating in a water bath at 30°C to obtain diisocyanate-terminated Prepolymer; then 0.52g 4,4'-diaminodiphenylmethane (0.5 times the mole number of hydroxyl-terminated polybutadiene) and 0.86g β-cyclodextrin (due to β-cyclodextrin The molecular weight of the hydroxyl-terminate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com