Method for preparing giant phospholipid vesicle by using finger-like microelectrode

A giant phospholipid and microelectrode technology, which is applied in the field of preparation of giant vesicles, can solve the problem of electrode non-coplanar electrode area, etc., and achieve the effect of small electrode use area, high yield, and good vesicle shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

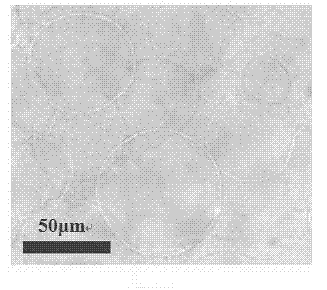

[0015] Specific embodiment 1: This embodiment prepares giant phospholipid vesicles according to the following method:

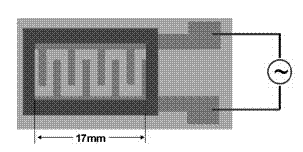

[0016] 1) Preparation and cleaning of electrodes. The prepared finger-shaped microelectrodes (the width of the interdigital fingers are 50~200μm) are ultrasonically cleaned with absolute ethanol and distilled water for 5~15min, then dried with nitrogen, and treated by a plasma cleaner for 20~30s for later use.

[0017] 2) Application and drying of phospholipids. The phospholipid (egg PC) is dissolved in chloroform (99.95v.%) to prepare a 2-20mg / mL phospholipid solution. Take 2-10μL of the phospholipid solution on the finger-shaped microelectrode, and apply the syringe needle back and forth 2-6 times. , To make it evenly spread on the finger-shaped microelectrode, and then put it in a vacuum dryer and vacuum dry for 2 hours to completely remove the residual chloroform solvent.

[0018] 3) Forming the assembly of the device. The dried finger-shaped microele...

specific Embodiment approach 2

[0020] Specific embodiment 2: This embodiment prepares giant phospholipid vesicles according to the following method:

[0021] 1) Preparation and cleaning of electrodes.

[0022] (1) ITO surface cleaning: ITO conductive glass is ultrasonically cleaned with ethanol and distilled water for 15 minutes, N 2 Blow dry, treat by plasma cleaning machine for 30s, and place on a heating plate to preheat at 110°C for 10 minutes.

[0023] (2) Laminator (GMP Photonex-Sync235) is set to preheat at 110℃, AM175 photoresist is pressed tightly on the ITO substrate to form a film, and the finger electrode mask is placed, and exposed and developed by soft UV (365nm) for 2s, 65℃ Heat and cure for 4min, with a mass percentage of 1.5% Na 2 CO 3 The solution was sonicated for 7 seconds and then washed, and the finger electrode pattern was initially obtained.

[0024] (3) The AUTOLAB PGSTAT302N electrochemical workstation adopts chronoamperometry to selectively corrode the finger electrodes. A hydrochloric a...

specific Embodiment approach 3

[0030] Specific embodiment 3: This embodiment prepares giant phospholipid vesicles according to the following method:

[0031] 1) Preparation and cleaning of electrodes. The prepared 50μm finger electrode was ultrasonically cleaned with absolute ethanol and distilled water for 10 minutes, then dried with nitrogen, and treated by a plasma cleaner for 20 seconds for later use.

[0032] 2) Application and drying of phospholipids. The phospholipid (egg PC) was dissolved in chloroform (99.95%) to prepare a 15mg / mL phospholipid solution, and 5μL of the phospholipid solution was applied to the finger microelectrode, and the syringe needle was used to apply back and forth 4 times to make it evenly spread on the The finger-shaped microelectrodes are then placed in a vacuum desiccator and dried under vacuum for 2 hours to completely remove the residual chloroform solvent.

[0033] 3) Forming the assembly of the device. The dried finger-shaped microelectrode coated with phospholipids...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Interdigital width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com