Coal-based environment-friendly solvent oil and preparation method thereof

An environmentally friendly solvent and shale technology, which is applied in the petroleum industry, hydrocarbon oil treatment, hydrogenation process, etc., can solve the problems of benzene content limitation, hematopoietic system disease and other problems, and achieve good lubricity, low freezing point and good performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

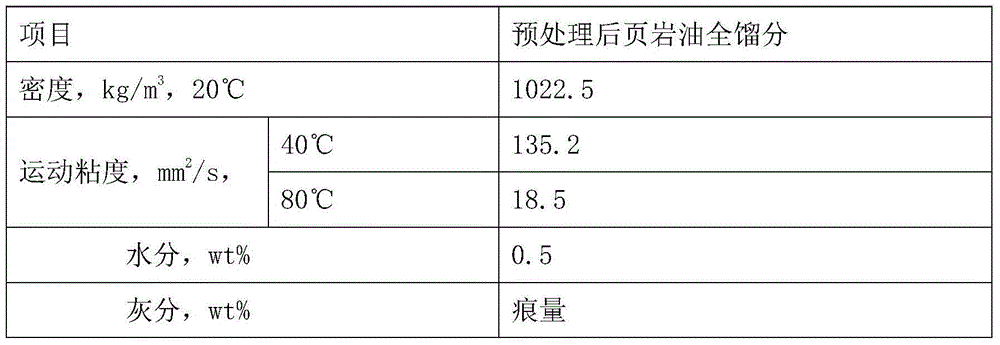

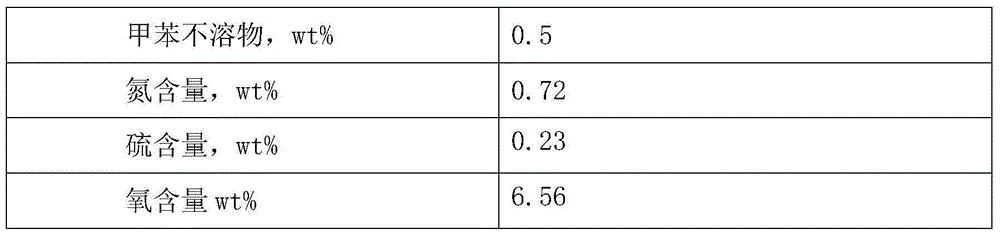

[0034] A typical shale oil is selected as the raw material, and the properties of the shale oil raw material after dehydration and removal of mechanical impurities are shown in Table 1. The shale oil raw material is distilled to separate light oil and heavy oil, light oil The distillation cut point of heavy oil and heavy oil is 350°C. The heavy oil is operated continuously on a 0.1t / d continuous suspension bed hydrocracking test device. The adopted process conditions are: reaction temperature 420°C, reaction pressure 15MPa, volume space velocity 0.5h -1 , the volume ratio of hydrogen to oil is 1500, the catalyst is a composite multi-metal active component containing molybdenum and iron, and the particle diameter is less than 50 μm in powder form. The amount of catalyst added is to control the total amount of metal in the active component and the weight of the heavy oil raw material The ratio is 0.8:100. The suspended bed light oil fraction produced by continuous operation and...

example 2

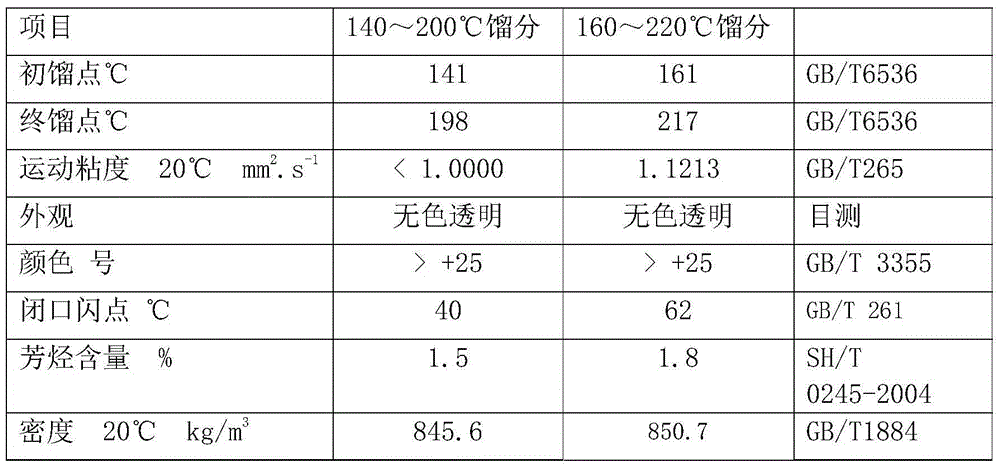

[0042] A typical coal tar was selected as the raw material for the test, and the properties of the coal tar raw material after dehydration and removal of mechanical impurities are shown in Table 3. The coal tar raw material was distilled to separate light oil and heavy oil, and the heavy oil was separated at 0.1 On the t / d continuous suspension bed hydrocracking test device, continuous operation, the adopted process conditions are: reaction temperature 430°C, reaction pressure 16MPa, volume space velocity 0.5h -1 , the volume ratio of hydrogen to oil is 1500, the catalyst is a composite multi-metal active component containing molybdenum and iron, and the particle diameter is less than 50 μm powder particles, the amount of catalyst added is to control the ratio between the total amount of metal in the active component and the weight of the coal tar raw material The ratio is 0.8:100. The suspended bed light oil fraction produced by continuous operation and the light oil separate...

example 3

[0050] The test selects a typical dephenolized oil fraction as raw material, and the properties of the dephenolized oil raw material after dehydration and removal of acid-base residue pretreatment are shown in Table 5. The dephenolized oil raw material is used as a fixed bed hydrorefining raw material, and then the The hydrogenation refining is carried out on the hr continuous hydrogenation unit, and the hydrofinishing process conditions are: two fixed bed reactors connected in series, the reaction pressure is 12.0MPa, the reaction temperature is 350°C, and the space velocity is 1.0h -1 , the volume ratio of hydrogen to oil is 800:1, and the catalysts are Ni-Mo series hydrogenation protecting agent and Ni-Mo-Wo series hydrofining catalyst. Hydrorefined coal tar hydrorefined oil is obtained.

[0051] The dephenolized oil obtained above is hydrotreated and refined, and then rectified, fractionated and cut to obtain fractions at 150-200°C or fractions at 160-200°C, etc., to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com