High-effective compound feed for late stage of tilapia cultivation and preparation method thereof

A tilapia and feed technology, applied in animal feed, animal feed, application and other directions, can solve the problems of low disease resistance, waste of resources, low feed utilization rate, etc., to prolong the storage time, reduce the loss of powder, protein Efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

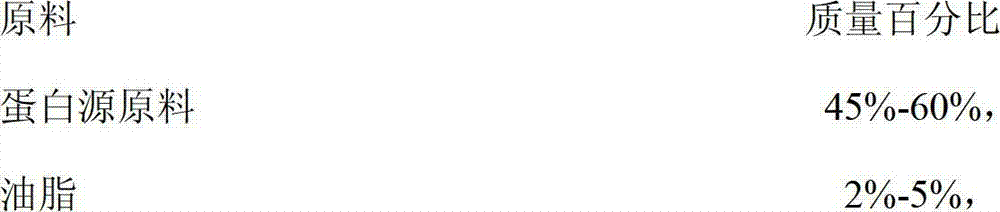

[0034] A tilapia feed (no fishmeal, common vegetable protein raw material), the mass fraction of its main nutrients is as follows, and the specific raw material selection and ratio are shown in Table 1:

[0035]

[0036] A kind of preparation method of tilapia rearing stage feed, its steps are:

[0037] A. After each raw material is crushed through a 40-mesh sieve, the protein source raw materials (soybean meal, rapeseed meal, feather meal, meat and bone meal, peanut meal, cotton meal, corn gluten meal) and carbohydrate raw materials contained in the formula shown in Table 1 are mixed (Secondary flour, corn flour, oily rice bran, wheat bran) are evenly mixed;

[0038] B. Mix multivitamins, multimineral salts, choline chloride, vitamin E, vitamin C, ferrous sulfate pentahydrate, and coated amino acids with the previous powder in stages;

[0039] C. Carry out extruded granulation processing according to conventional aquatic extruded feed processing equipment and methods;

...

Embodiment 2

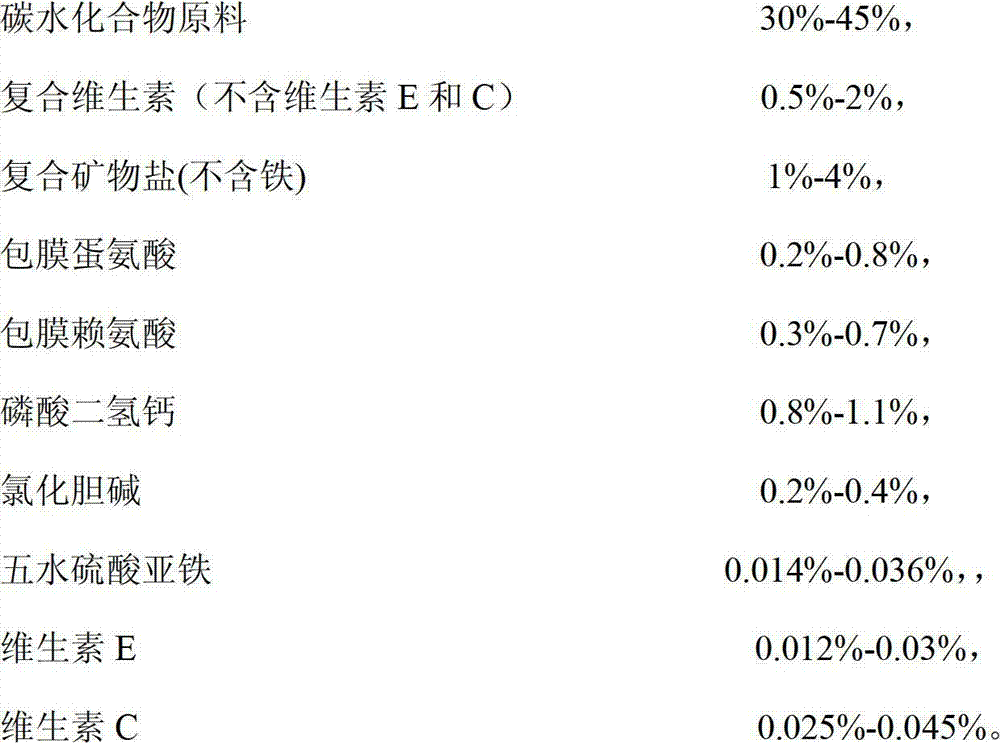

[0043] A kind of tilapia feed (without fish meal, adding low-priced feed sources such as feather meal, meat and bone meal and palm oil), the mass fraction of its main nutrients is as follows, and the specific raw material selection and proportioning are shown in Table 1:

[0044]

[0045] The preparation steps are the same as in Example 1.

[0046] Raise about 220g of Gifu tilapia for 56 days with the feed formulated by formula 2 shown in Table 1, and use a commercially available certain tilapia equivalent feed as a contrast, and raise it in a pond cage (1m × 1m × 1.5m), 5 repetitions per group, 20 tails per repetition. After the experiment, the final body weight of the fish in the formula 2 group was 548g, the weight gain rate was 149%, the specific growth rate was 1.63, the protein efficiency was 259%, and the feed coefficient was 1.35, which were significantly improved compared with the control diet. Serum triglyceride, total cholesterol, aspartate aminotransferase, ala...

Embodiment 3

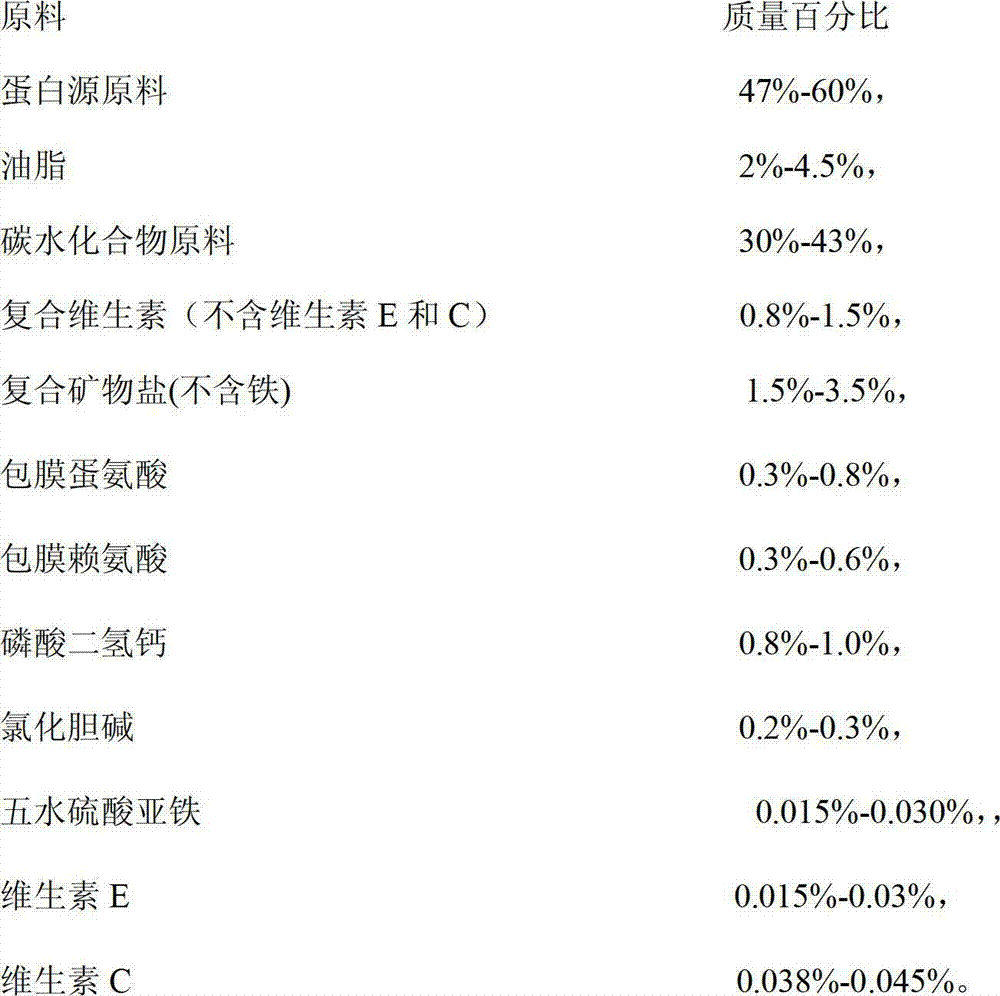

[0048] A tilapia feed (containing a small amount of fishmeal, without soybean meal), the mass fraction of its main nutrients is as follows, and the specific raw material selection and proportioning are shown in Table 1:

[0049]

[0050] The preparation steps are the same as in Example 1.

[0051] With the formula 3 feed shown in Table 1, about 218g of Gifu tilapia was fed for 56 days, and a commercially available tilapia equivalent feed was used as a control, and it was raised in a pond cage (1m×1m×1.5m). Each group 5 repetitions, 30 tails per repetition. After the experiment, the final body weight of the fish in the formula 3 group was 567g, the weight gain rate was 160%, the specific growth rate was 1.70, the feed coefficient was 1.32, and the protein efficiency was 266%. All indicators were significantly better than the control feed. Simultaneous serum complement C 3 、C 4 The content of S. iniae significantly increased, and after infection with Streptococcus iniae, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com