Expansion of application of penicillium lipase in biodiesel preparation

A biodiesel and lipase technology, applied in the field of bioengineering, can solve the problems of time-consuming and laborious, unclear goals, and inconspicuousness, and achieve the effects of high efficiency, clear breeding goals, and high biodegradability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

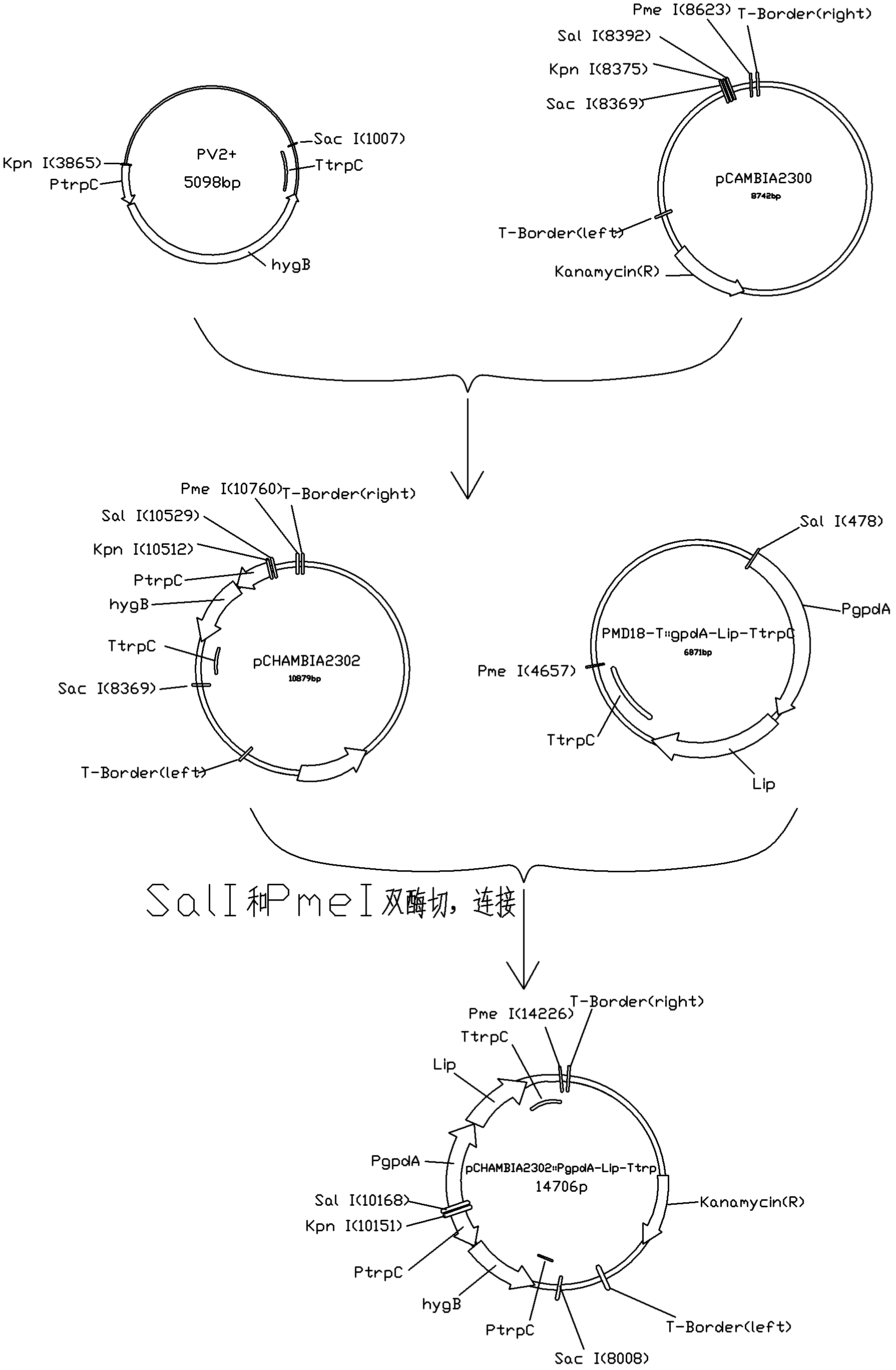

[0049] Embodiment 1, the construction of overexpression vector

[0050] Take the following steps:

[0051] (1) utilize restriction endonuclease Sac I, Kpn I to hygromycin resistance expression cassette from plasmid PV2 + The fragments were excised by the upper enzyme, and the fragments were recovered by gel, and cloned into the corresponding restriction site of the pCAMBIA2300 plasmid to obtain the recombinant plasmid pCHAMBIA2302 with hygromycin resistance; the hygromycin expression cassette can also be derived from any other DNA containing this sequence Or directly synthesized, the plasmid that is used to construct PEL gene overexpression vector except pCAMBIA2300, can also use the pCAMBIA series carrier such as pCAMBIA1300, pCAMBIA3300 etc. and pHB carrier that can express in filamentous fungus;

[0052] (2) According to the sequence design primer (forward primer: TG) of the lipase gene PEL (AF330635) of Penicillium expanded ACTAGT ATGTTGTTCAACTACCAATCTTT The underlined ...

Embodiment 2

[0058] Embodiment two, the acquisition of Penicillium genetically engineered bacteria

[0059] The acquisition of the Penicillium genetically engineered bacterium comprises the following steps:

[0060] (1) Pick the isolated and purified wild-type Penicillium and inoculate it on a PDA plate, cultivate it at 28°C for about 20 days, and wash the mature spores with sterile water;

[0061] (2) Inoculate the engineered Agrobacterium EHA105 containing the final vector pCHAMBIA2302::PgpdA-PEL-TtrpC in Example 1 in the LB liquid medium containing streptomycin and kanamycin (both 100 μg / ml) at 28°C, Cultivate overnight at 200 rpm, reactivate with MM medium containing streptomycin and kanamycin (both 100 μg / ml), and culture at 220 rpm for 48 hours at 28°C. Take an appropriate amount of culture and centrifuge at 5000rpm to remove the supernatant, wash with 1M liquid medium, and finally dilute to OD600=0.15 with 1M liquid medium, then cultivate at 28°C and 220rpm for 6-8 hours until OD60...

Embodiment 3

[0070] The application of the present invention is the transesterification reaction completed on the organic solvent oil-water interface, and the esterification rate of the transesterification synthesis can reach 85-95%.

[0071] The lipase used in the present invention is the modified Penicillium extensa lipase obtained by the present invention, and then adopts the method of immobilization treatment, wherein, the immobilization method comprises the following steps: adding enzyme powder in the buffer solution, stirring Make it fully dissolved, then add a certain amount of diatomaceous earth into the enzyme solution, shake at a constant temperature for a certain period of time, collect the solid by centrifugation, wash the immobilized carrier with acetone for 3-5 times to disperse the carrier particles, and then wash with distilled water for 3 -5 times, the acetone was washed away, and the immobilized lipase was obtained after freeze-drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com