Preparation method of titanium dioxide nanotube thin film with visible-light activity

A technology based on titanium dioxide and visible light, which is applied in chemical instruments and methods, photosensitive equipment, and climate sustainability. It can solve the problems of limited application range, low sunlight utilization rate, and large band gap, and achieve simple process and enhanced photoelectricity. The effect of response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

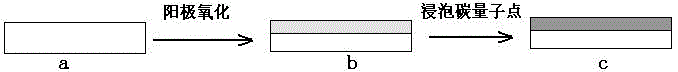

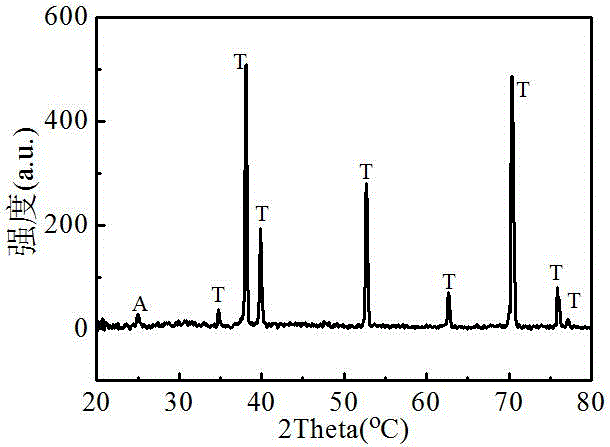

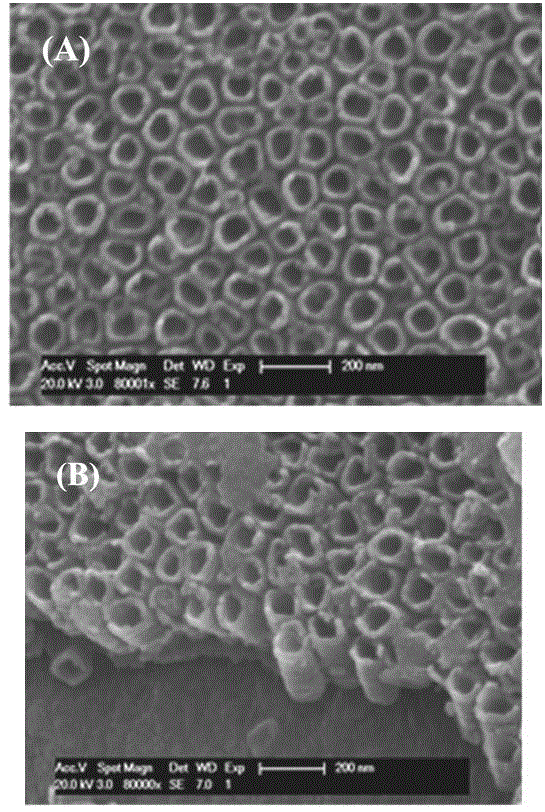

[0022] The Ti sheet treated with the polishing solution was used as the anode, the graphite sheet was used as the cathode, and the 0.5% HF solution was used as the electrolyte, and the voltage of 20V was controlled by a DC stabilized power supply, anodized for 40 min under magnetic stirring, and finally washed repeatedly with deionized water clean and dry with air flow to obtain TiO 2 nanotube film. In the muffle furnace, after 450 o C annealing treatment for 2 hours, you can get anatase TiO 2 nanotubes (such as figure 2 shown).

[0023] The carbon quantum dot solution was prepared by electrochemical anodic oxidation method. Preparation of Carbon Quantum Dots Modified TiO by Direct Impregnation Assembly 2 nanotube film. TiO 2 The nanotube film was immersed in the carbon quantum dot solution for 3 hours. Take out the sample, wash off the residual liquid on the surface with deionized water, and put it under N 2 Blow dry on airflow and set aside.

[0024] A three-elec...

Embodiment 2

[0026] TiO 2 The preparation process of the nanotube thin film is as in Example 1. TiO2 The nanotube film was immersed in the carbon quantum dot solution for 6 hours. Remove the sample, rinse off the surface solution with deionized water, and 2 Blow dry on airflow and set aside.

[0027] A three-electrode system was used to test the photoelectrochemical performance of thin film electrodes, and TiO 2 The nanotube film electrode is the working electrode, the platinum sheet is the counter electrode, the Ag / AgCl electrode is the reference electrode, and the electrolytic cell with a quartz window is selected, and the electrolyte is 0.5 mol . L -1 Na 2 SO 4 solution. CHI660A electrochemical workstation produced by Shanghai Chenhua Instrument Co., Ltd. was used. The simulated sun light source adopts a 500W short-arc xenon lamp produced by Beijing Changtuo Technology Co., Ltd. The incident light passes through a quartz water tank to filter out infrared light to obtain ultravi...

Embodiment 3

[0029] TiO 2 The preparation process of the nanotube thin film is as in Example 1. TiO 2 The nanotube film was immersed in the carbon quantum dot solution for 9 hours. Remove the sample, rinse off the surface solution with deionized water, and 2 Blow dry on airflow and set aside.

[0030] A three-electrode system was used to test the photoelectrochemical performance of thin film electrodes, and TiO 2 The nanotube film electrode is the working electrode, the platinum sheet is the counter electrode, the Ag / AgCl electrode is the reference electrode, and the electrolytic cell with a quartz window is selected, and the electrolyte is 0.5 mol . L -1 Na 2 SO 4 solution. CHI660A electrochemical workstation produced by Shanghai Chenhua Instrument Co., Ltd. was used. The simulated sun light source adopts a 500W short-arc xenon lamp produced by Beijing Changtuo Technology Co., Ltd. The incident light passes through a quartz water tank to filter out infrared light to obtain ultra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com