Method of preparing GaN monocrystal substrate in mechanical removal way

A gallium nitride single crystal and substrate technology, applied in chemical instruments and methods, single crystal growth, single crystal growth, etc., can solve problems such as complex equipment, affecting crystal quality, and separation difficulties, and achieve smooth surface without cracks, The effect of high crystal quality and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation method of the gallium nitride single crystal substrate of this embodiment includes the following steps:

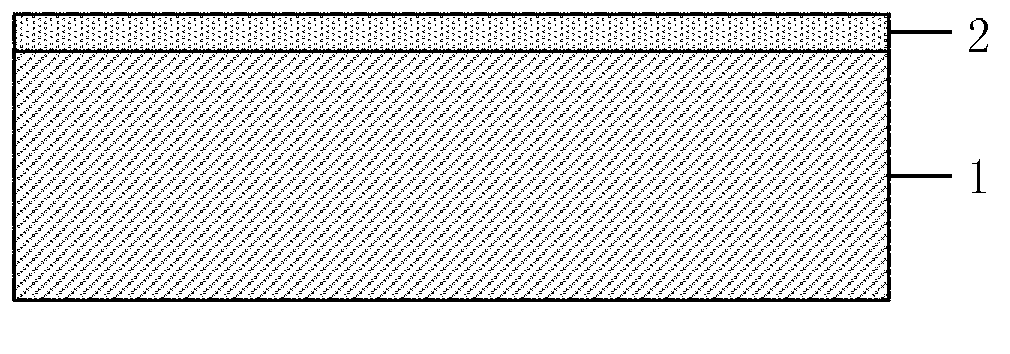

[0032]1) Using molecular beam epitaxy (MBE) to pre-deposit boron nitride h-BN film 2 on the surface of sapphire substrate 1: first, clean the surface of the commercial sapphire substrate with acetone, alcohol and deionized water, and wash the cleaned The sapphire substrate is placed in the MBE reaction chamber, and a hexagonal boron nitride film is deposited on the surface of the sapphire, with a thickness of 20nm, and the growth temperature is between 600~700°C, such as figure 1 shown;

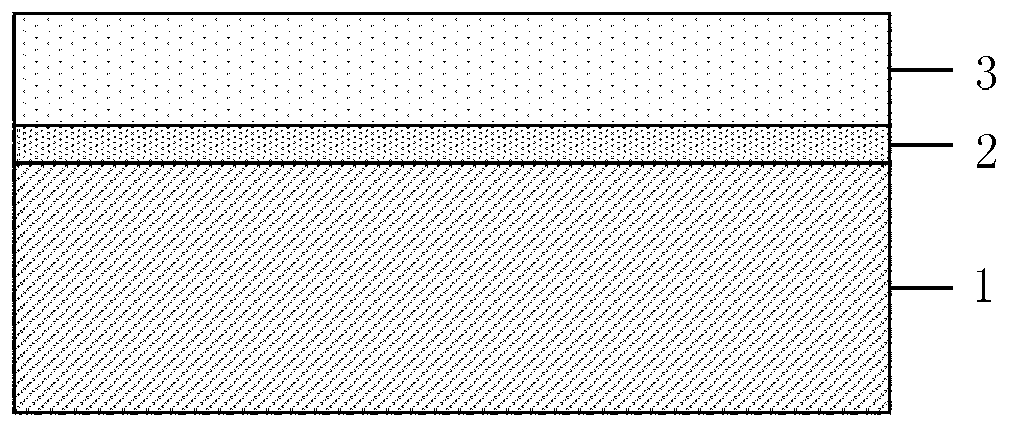

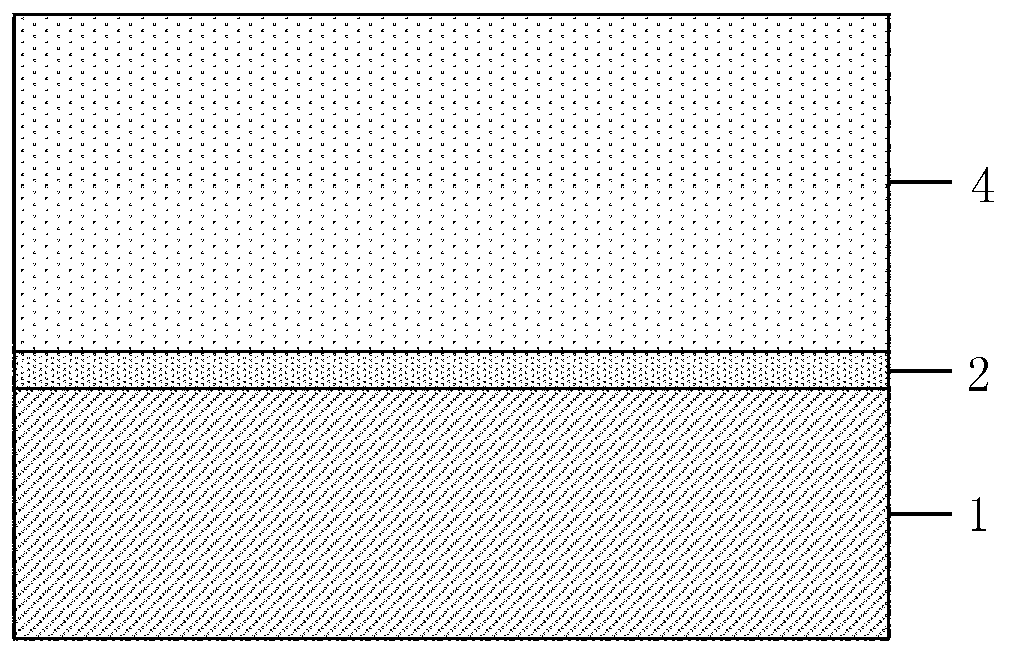

[0033] 2) Put it into the MOCVD reaction chamber for a growth to form a GaN single crystal film 3: first raise the temperature to a temperature lower than 600°C to grow a low-temperature buffer layer with a thickness of 30nm; then raise the temperature to 900~1100°C GaN is grown at high temperature to form a GaN single crystal film with a thickness of 4 μm, such as...

Embodiment 2

[0038] 1) Pre-deposit hexagonal boron nitride film h-BN on the surface of the sapphire substrate by magnetron sputtering: first, clean the surface of the commercial sapphire substrate with acetone, alcohol and deionized water; The sapphire substrate is placed in the reaction chamber of the magnetron sputtering apparatus, and a hexagonal boron nitride film is deposited on the surface of the sapphire, with a thickness of 20nm and a growth temperature of 600~700°C;

[0039] 2) Put it into the MOCVD reaction chamber for one growth to form a GaN single crystal film: first raise the temperature to a temperature lower than 600°C to grow a low-temperature buffer layer with a buffer layer thickness of 30nm; then raise the temperature to 900~1100°C to grow GaN at a high temperature , forming a GaN single crystal film with a thickness of 4 μm;

[0040] 3) Surface treatment before the secondary growth of HVPE, including organic cleaning and removal of the oxide layer; secondary growth of ...

Embodiment 3

[0043] 1) Using solid source molecular beam epitaxy (SSMBE) to pre-deposit graphene film on the surface of sapphire substrate: first, the surface of commercial sapphire substrate is cleaned with acetone, alcohol and deionized water, and the cleaned sapphire substrate is Put it into the SSMBE reaction chamber, deposit graphene film on the surface of sapphire, the thickness is 20nm, and the growth temperature is 600~700°C;

[0044] 2) Put it into the MOCVD reaction chamber for one growth to form a GaN single crystal film: first raise the temperature to a temperature lower than 600°C to grow a low-temperature buffer layer with a buffer layer thickness of 30nm; then raise the temperature to 900~1100°C to grow GaN at a high temperature , forming a GaN single crystal thick film with a thickness of 4 μm;

[0045] 3) Surface treatment before secondary growth of HVPE, including organic cleaning and removal of oxide layer; secondary growth of HVPE in HVPE reaction chamber to form GaN si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Growth temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com