Enzyme-sensitive supramolecular hydrogel nano material, gelator and preparation method of gelator

A technology of supramolecular hydrogel and nanomaterials, which is applied in the field of supramolecular hydrogel and gel factor and its preparation, can solve the problems of difficult control and complicated preparation process, and achieve easy preparation, simple synthesis, and gelation conditions easily controlled effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Glycine-glycine-glycine-aspartic acid-valine-glutamic acid-aspartic acid and glycine-glycine-glycine-valine-aspartic acid-glutamic acid were first synthesized by solid-phase peptide synthesis -Aspartic acid two oligopeptide fragments were synthesized separately.

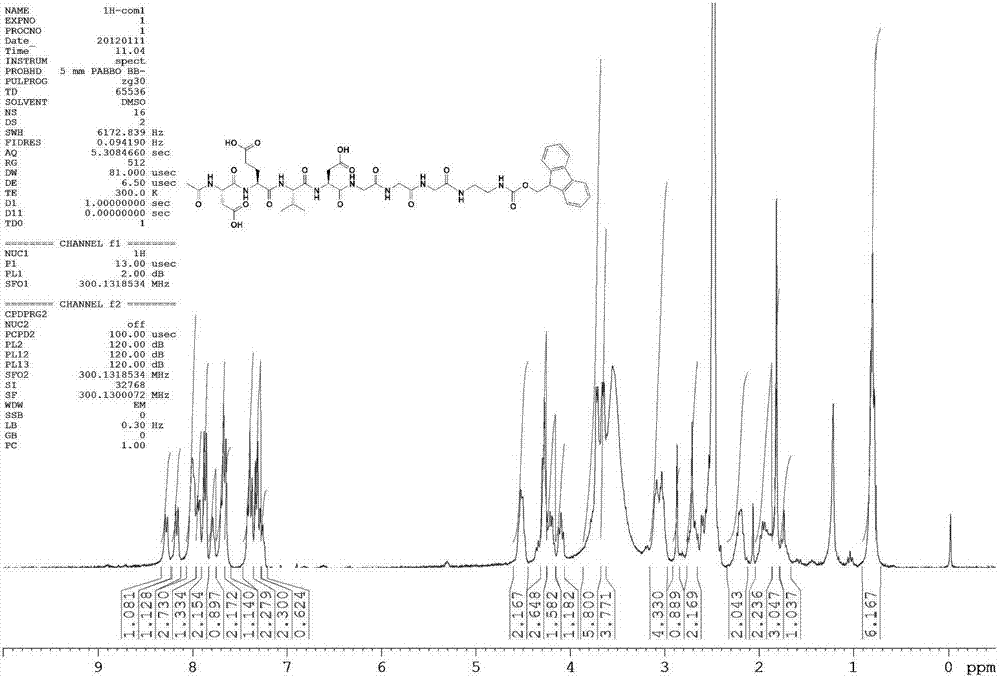

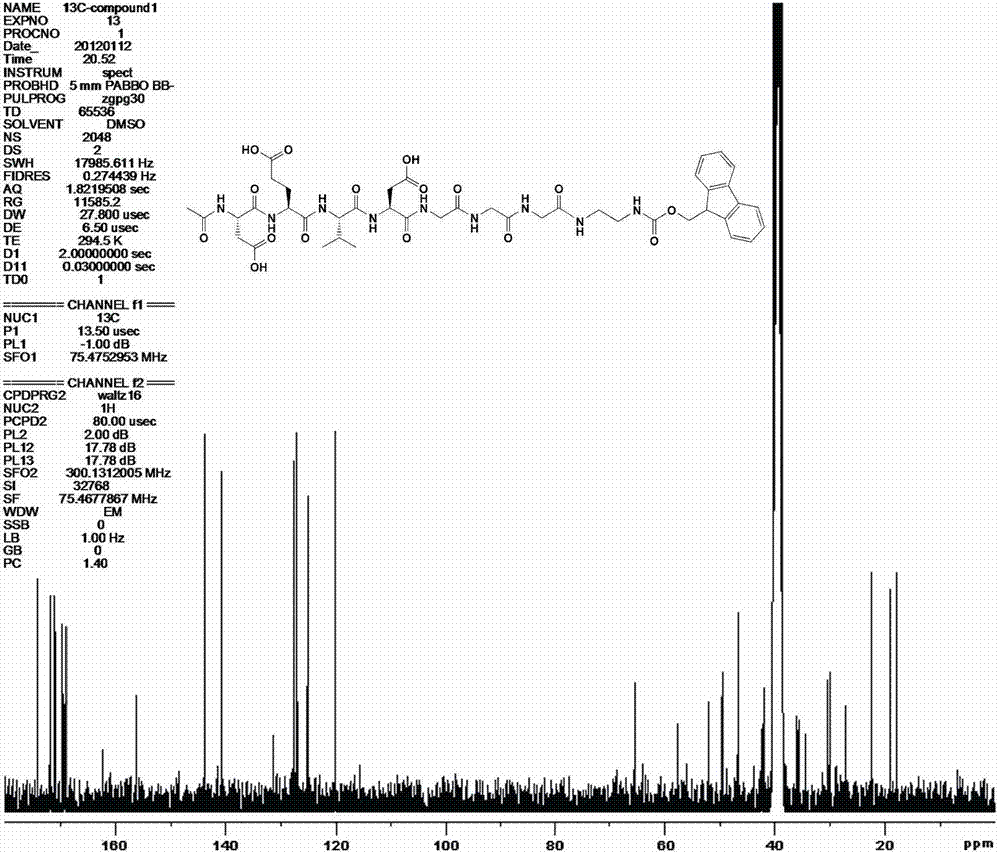

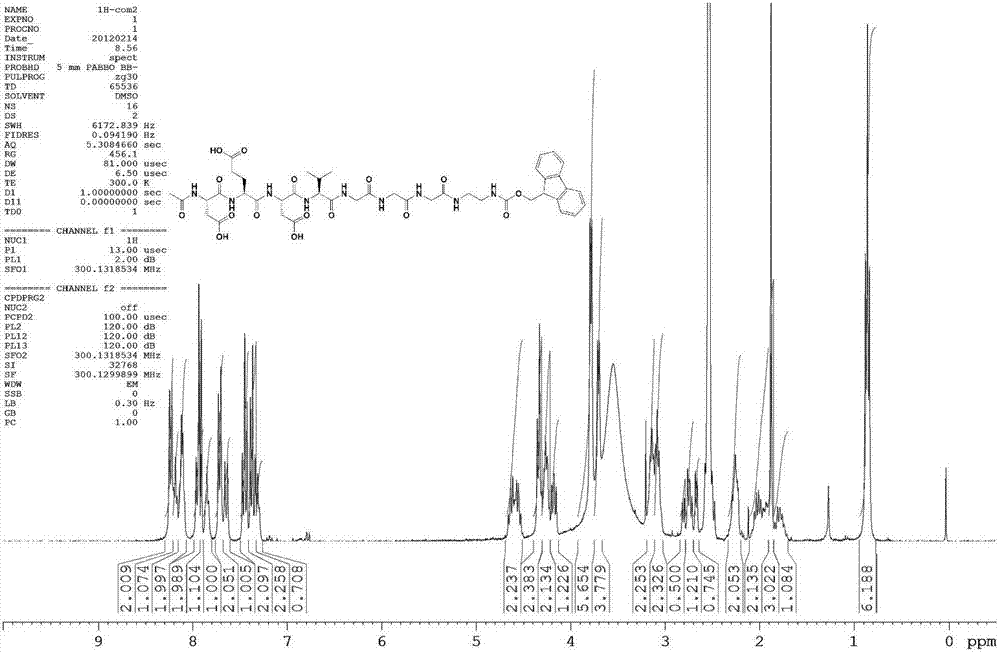

[0032] The first pure compound Y in this example 1 (Fmoc-EDA-Gly-Gly-Gly-Gly-Asp-Val-Glu-Asp-Acetyl) The synthetic route is as follows:

[0033]

[0034] The oligopeptide sequence glycine-glycine-glycine-aspartic acid-valine-glutamic acid-aspartic acid was first synthesized by solid-phase peptide synthesis method, according to: 1 mmol of 2-chlorotrityl chloride resin After swelling in 2-3 ml of N,N-dimethylformamide for 4-8 minutes, add 2 mmol of N-fluorenylmethoxycarbonyl-glycine, and then add 2 mmol of N,N-diisopropylethylamine , after 2-3 hours of reaction, react with 100 microliters of methanol for 5-10 minutes, cut off the fluorenyl moxycarbonyl protecting group of glycine, Kaiser test shows blue col...

Embodiment 2

[0046] Embodiment 2: In vitro enzyme activity detection experiment

[0047] In the in vitro experiment of this embodiment, the first pure compound Y with a concentration of 0.28 mmol per liter was used. 1 , in a concentration of 50 millimoles per liter of 4-hydroxyethylpiperazineethanesulfonic acid, 0.1% of 3-[(3-cholesterylaminopropyl) dimethylamino]-1-propanesulfonic acid, 50 milliliters Molar sodium chloride per liter, 10 mmol per liter of ethylenediaminetetraacetic acid and 5 caspase 3 with a unit volume of 50 microliters in a total volume of 60 microliters, incubated at 37 degrees Celsius Enzyme recognition and cleavage were completed in 100 minutes; the second pure compound Y was used at a concentration of 0.28 mmol per liter 2 , in a concentration of 50 millimoles per liter of 4-hydroxyethylpiperazineethanesulfonic acid, 0.1% of 3-[(3-cholesterylaminopropyl)dimethylamino]-1-propanesulfonic acid, 50 milliliters Molar sodium chloride per liter, 10 mmol per liter of ethy...

Embodiment 3

[0050] Embodiment 3: cell biocompatibility experiment

[0051] Firstly, the culture of human hepatoma cell HepG2 was carried out: at a volume concentration of 5% CO 2 The human liver cancer cell line HepG2 was cultured in a 37°C incubator in an air environment using DMEM medium containing 10% bovine serum albumin by volume; the cells in the logarithmic growth phase were washed three times with 0.01 moles per liter of sterile PBS buffer , and then digested with trypsin at a mass volume concentration of 0.25%; the sub-disc cells were rinsed with DMEM, then counted, and the cell concentration was diluted to 3×10 per ml 4 cells.

[0052] Then use human liver cancer cell HepG2 seed plate: plant HepG2 cells into 96-well microwell plate, 3×10 per well 3 cells in a volume concentration of 5% CO 2 DMEM medium containing 10% bovine serum albumin by volume was used for 24 hours in a 37°C incubator in an air environment.

[0053] Test the first pure compound Y separately 1 and a seco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com