Lithium ion battery diaphragm with special structure and preparation method thereof

A lithium-ion battery and a special structure technology, applied in structural parts, battery pack parts, circuits, etc., can solve the problems of difficult to obtain uniform slurry, limit the electrical performance of the diaphragm, reduce the porosity of the diaphragm, and achieve large-scale industrialization Production, film thickness can be adjusted at will, and the effect of lithium ion conductivity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

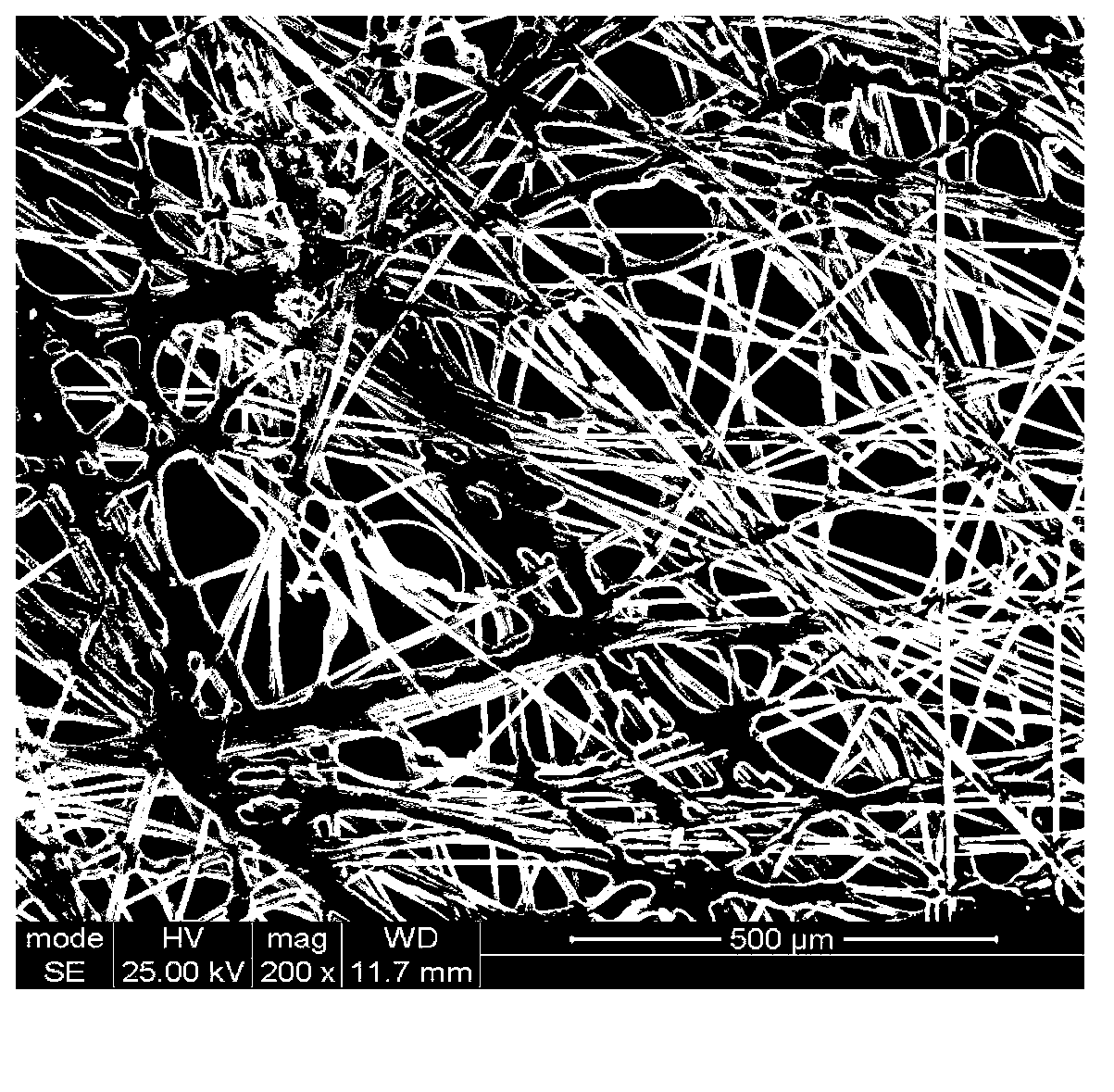

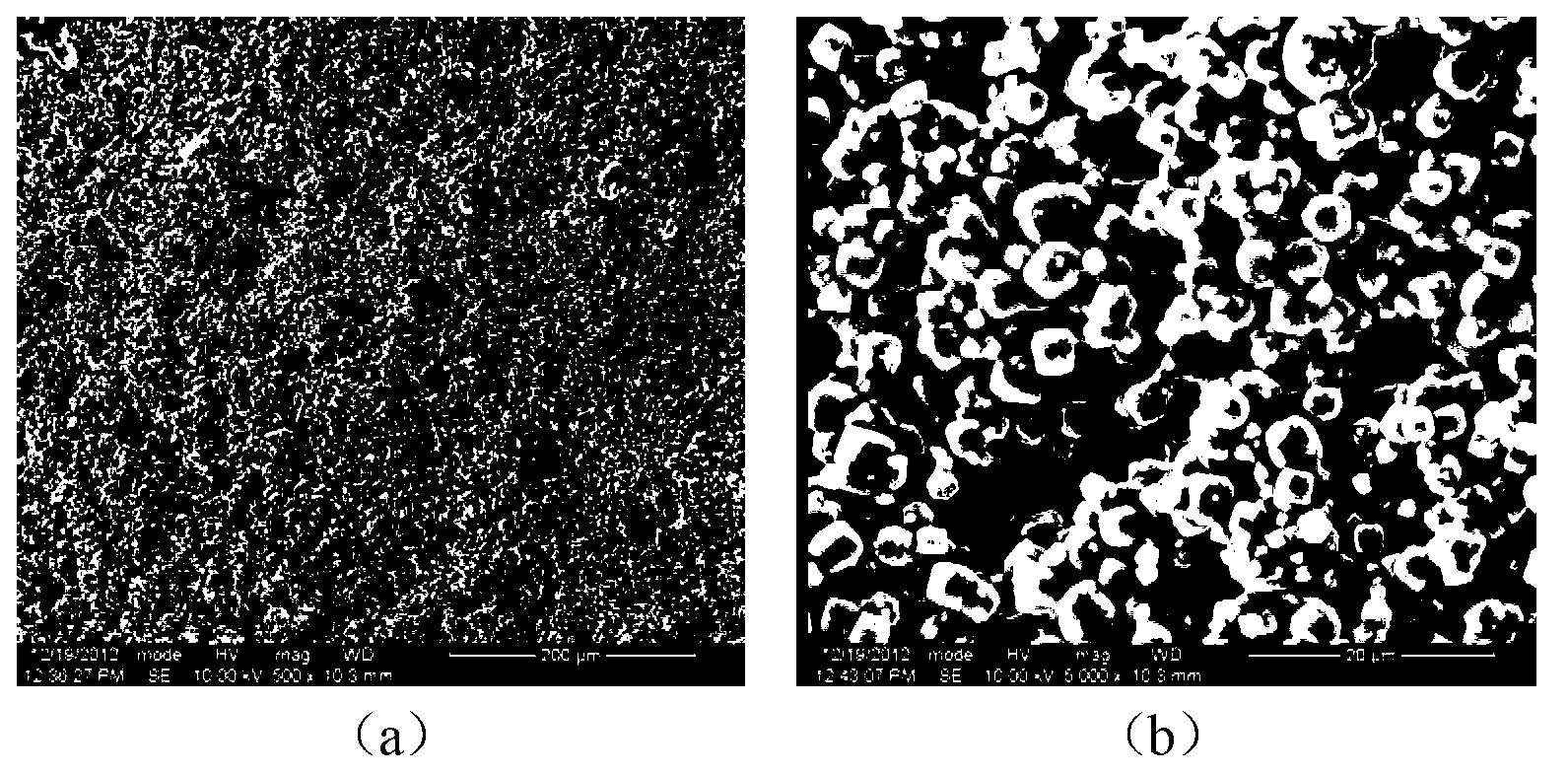

[0035] Slowly add 8g of polyurethane thickener to 200ml of ethanol, stir vigorously and mix evenly. Add 24g of NaA-type zeolite particles (with a particle size of about 2.5 μm) to the above solution, and continue to stir for 2 hours to obtain a uniformly mixed suspension. Then add 6.5g of polypropylene microspheres (particle size is about 0.8μm) to the above suspension, continue to stir for 4h, and obtain a uniform coating slurry after vacuum defoaming treatment. Using a dip coating machine, polyester non-woven fabric (gram weight 17 g / square meter, thickness 20 μm, porosity 65%, pore size distribution uniform, average pore size 18 μm, see figure 1 ) before and after coating the above slurry, the dipping time is 120s, the pulling speed is 1cm / s, dipping once. After coating, it was dried in a constant temperature oven at 40°C for 5 hours, and finally rolled into a tablet press at 150°C with a roller spacing of 50 μm to obtain an inorganic-coated lithium-ion battery separator. ...

Embodiment 2

[0038] Slowly add 8g of polyurethane thickener to 200ml of ethanol, stir vigorously and mix evenly. Add 24g Al to the above solution 2 o 3 Particles (particle size is about 1.0 μm), continue to stir for 2 hours to obtain a well-mixed suspension. Then add 6.5g of polypropylene microspheres (particle size is about 0.8μm) to the above suspension, continue to stir for 4h, and obtain a white uniform coating slurry after vacuum defoaming treatment. Use a dip coating machine to coat the above slurry on both sides of the polyester non-woven fabric (weight 25 g / m2, thickness 20 μm, porosity 60%, uniform pore size distribution, average pore size 10 μm), and the dipping time is 120s , the pulling speed is 1cm / s, dipping once. After coating, it was dried in a constant temperature oven at 40°C for 5 hours, and finally rolled into a tablet press at 150°C with a roller spacing of 80 μm to obtain an inorganic-coated lithium-ion battery separator.

[0039] In this example, the technical pa...

Embodiment 3

[0041] Slowly add 1.5g sodium carboxymethylcellulose into 200ml water, stir vigorously and mix well. Add 24g of NaA-type zeolite particles (with a particle size of about 2.5 μm) to the above solution, and continue to stir for 2 hours to obtain a uniformly mixed suspension. Then add 6.5g of polystyrene microspheres (particle size is about 0.6μm) to the above suspension, continue to stir vigorously for 4h, and obtain a white uniform coating slurry after vacuum defoaming treatment. Use a dip coating machine to coat the above slurry on both sides of the porous polypropylene base film (thickness 22 μm, porosity 40%, uniform pore size distribution, average pore size 1.0 μm), the dipping time is 150 s, and the pulling speed is 1 cm / s, impregnated twice. After coating, it was dried in a constant temperature oven at 40°C for 5 hours, and finally rolled into a tablet press at 120°C with a roller spacing of 30 μm to obtain an inorganic-coated lithium-ion battery separator.

[0042] In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com