Comprehensive recycling method for metals in superalloy scrap

A technology of superalloy and nickel-based superalloy, which is applied in the field of nickel-based superalloy and can solve the problems of low direct yield of rare metals, large acid consumption and loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

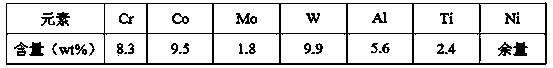

[0021] A certain type of nickel-based superalloy is used as the raw material, and the composition is as follows:

[0022]

[0023] Cut 10kg of the above nickel-based superalloy waste into 1cm, melt it in an intermediate frequency melting crucible, and atomize it into alloy metal powder of 23 μm by gas atomization, mix the alloy metal powder with the particle size of 100 μm Silica powder (purity greater than 99%) is mixed uniformly at a volume ratio of 1:1, placed on a quartz sand core layer, and a metal powder bed with a thickness of 2cm is constructed, and then heated in a tube furnace at a heating rate of 2°C / min. The metal powder bed layer was heated up to 400°C, and at the same time, oxygen gas with a pressure of 1.5 atmospheres and a flow rate of 200ml / min was introduced from bottom to top. Nitrogen and chlorine gas with a pressure of 1.2 atmospheres are introduced from bottom to top, the flow rate of nitrogen gas is 200ml / min, and the flow rate of chlorine gas is 100m...

Embodiment 2

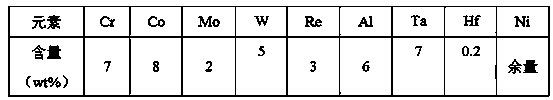

[0025] A certain type of nickel-based superalloy is used as the raw material, and the composition is as follows:

[0026]

[0027]Cut more than 15kg of nickel-based superalloy waste into 1.5cm, melt it in an intermediate frequency melting crucible, and atomize it into 10μm alloy metal powder by gas atomization, and mix the alloy metal powder with a particle size of 150μm Silicon oxide powder (purity greater than 99%) is mixed uniformly at a volume ratio of 1:1, placed on a quartz sand core layer, and a metal powder bed with a thickness of 6cm is constructed, and then the tube furnace is heated at a heating rate of 5°C / min. The metal powder bed in the furnace is heated to 500°C, and at the same time, oxygen gas with a pressure of 2 atmospheres and a flow rate of 2000ml / min is introduced from bottom to top, and the temperature is kept for 2 hours, then the temperature is lowered to 400°C, and the oxygen flow is stopped, and then Nitrogen and chlorine gas with a pressure of 2 ...

Embodiment 3

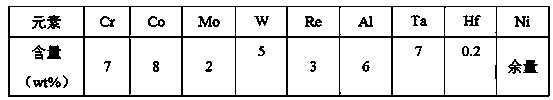

[0029] A certain type of nickel-based superalloy is used as the raw material, and the composition is as follows:

[0030]

[0031] Cut more than 12kg of nickel-based superalloy waste into 2cm, melt it in an intermediate frequency melting crucible, and atomize it into 50μm alloy metal powder by gas atomization, mix the alloy metal powder with the particle size of 110μm The silicon oxide powder is mixed evenly at a volume ratio of 1:1, placed on the quartz sand core layer, and a metal powder bed with a thickness of 10cm is constructed, and then the metal powder bed in the tube furnace is heated up at a heating rate of 2.5°C / min. to 450°C, while feeding compressed air with a pressure of 1.8 atmospheres and an air flow rate of 1500ml / min from bottom to top, keeping it warm for 1 hour, then cooling down to 350°C, and stopping the introduction of compressed air, and then from bottom to top Introduce nitrogen and chlorine gas at a pressure of 1.5 atmospheres, wherein the flow rate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com