Deoxidation catalyst for olefin gas, preparation method and application thereof

A technology of deoxidation catalysts and olefins, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve problems such as high operating temperature, high price, frequent regeneration, etc. Achieve the effects of low operating temperature, good stability and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Preparation of vector

[0043] Dry mixing method: Weigh 146g of pseudo-boehmite and 5g of nano-titanium dioxide, roast at 800°C for 2 hours, mix evenly, and use the rolling ball forming process to make a ball with a diameter of 2 to 4mm to obtain TiO 2 5% TiO 2 / Al 2 o 3 Composite carrier, denoted as TA-01.

[0044] Sol-gel method: Take 85ml of tetra-n-butyl titanate and slowly add it dropwise to absolute ethanol, and add it while stirring.

[0045] Add the inhibitor glacial acetic acid, stir vigorously to form a colloidal solution, add deionized water to the solution, and slowly add 80gAl 2 o 3 , forming a gel. Then the gel was dried at constant temperature at 80°C for 10h, and the dried crystal was calcined at 300°C for 10h to obtain TiO 2 20% TiO 2 / Al 2 o 3 Composite carrier, denoted as TA-02.

[0046] Co-precipitation method: take 50.3g of titanium sulfate or 23.7g of titanium tetrachloride, and 376g of aluminum nitrate, dissolve them in deionized water,...

Embodiment 2

[0048] Weigh 0.017g of palladium chloride and 57.5g of manganese nitrate tetrahydrate and dissolve in water to make a solution, weigh 80g of carrier TA-01, immerse in the above prepared solution, immerse at room temperature for 6h, dry at 80°C for 5h, and 300°C After roasting for 5 hours, a deoxidation catalyst with a Pd content of 0.01% (based on the weight of the carrier, the same below) and a Mn content of 20% (based on the weight of the oxide, the same below) was obtained. Randomly extract 20ml of the catalyst and put it into the reactor. Feed ethylene feed gas, the gas space velocity is 2000h-1, the reaction temperature is 200°C, the pressure is 5.0MPa, and the inlet oxygen content is about 2000ppm. The outlet oxygen content is lower than 0.05ppm.

Embodiment 3~6

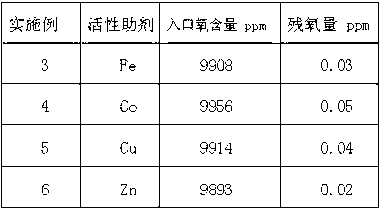

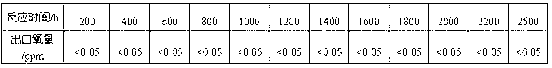

[0050] Weigh 21.3g of chloroplatinic acid and dissolve it in water, divide it into 4 parts, weigh 34.7g of ferrous sulfate, 38.8g of cobalt nitrate, 30.4g of copper nitrate and 16.8g of zinc chloride, dissolve them in water, and mix them with Pt solution Impregnation solution: Weigh 88g carrier TA-02 and immerse in each of the above impregnation solutions, immerse at room temperature for 5h, dry at 150°C for 5h, and roast at 600°C for 2h to obtain the active component with a Pt content of 2.0%. The content of Fe, Co, Cu and Zn are all 10% deoxidation catalyst. Randomly extract 20ml of each catalyst and put it into the reactor, feed ethylene feed gas, the gas space velocity is 20000h-1, the reaction temperature is 60°C, the pressure is 0.1MPa, and the inlet oxygen content is about 9900ppm. The outlet oxygen content is lower than 0.05ppm. The results are shown in Table 1.

[0051] Table 1 The deoxidation performance of the catalysts of Examples 3-6

[0052]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com