Method for cleaning and producing lincomycin

A technology of lincomycin and production methods, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve environmental pollution and other problems, and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

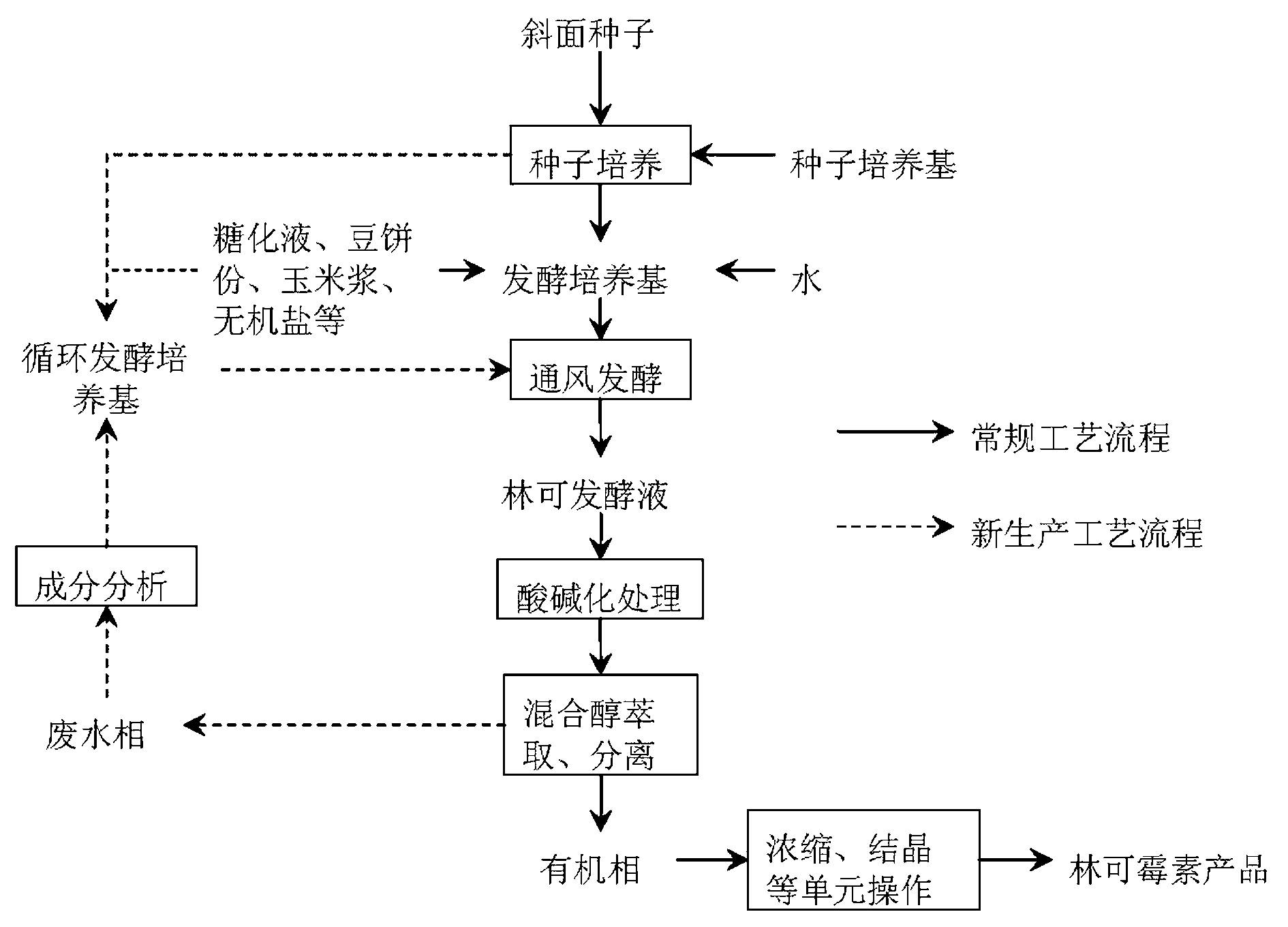

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: preparation of lincomycin seed solution

[0022] The lincomycin-producing bacterium is Streptomyces lincolnensis lincomycin-producing bacterium ( Streptomyces lincolnensis ) CPCC-200038 strain

[0023] Slant medium: 2% starch, 0.05% sodium chloride, 0.5% potassium nitrate, 0.1% dipotassium hydrogen phosphate, 0.05% magnesium sulfate, 0.01‰ ferrous sulfate, 1.8% agar, the balance is water, and the pH is natural.

[0024] Seed medium: 1.5% starch, 3% glucose, 1.5% bean cake powder, 2.5% corn steep liquor, 0.2% sodium nitrate, 0.2% ammonium sulfate, 0.05% potassium dihydrogen phosphate, 0.5% calcium carbonate, 0.05% soybean oil, foam enemy 0.01%, the balance is water, pH value: 7.6~7.8 (before elimination).

[0025] Mother slant seed preparation: in a sterile room, take 1 / 5 shovel of sandy soil spores and inoculate them on the sterile and normal test tube slant after one day of cultivation under aseptic conditions, spread evenly, and cultivate at 29°C with ...

Embodiment 2

[0033] Embodiment 2: the preparation of lincomycin fermented liquid

[0034] Initial fermentation medium: starch saccharification solution 6.5%, soybean cake powder 2%, corn steep liquor 1.5%, ammonium sulfate 0.38%, calcium carbonate 0.8%, sodium chloride 0.68%, potassium dihydrogen phosphate 0.03%, the balance is water, pH6.5~8.0.

[0035] Feed medium 1: soybean cake powder 10%, corn steep liquor 18%, calcium carbonate 0.8%, soybean oil 0.05Kg / m 3 , bubble enemy 0.01 Kg / m 3 , the balance is water, and the pH is natural.

[0036] Feed medium 2: soybean cake powder 4%, corn steep liquor 6%, sodium nitrate 2%, ammonium sulfate 1%, potassium dihydrogen phosphate 0.05%, calcium carbonate 0.5%, soybean oil 0.05Kg / m 3 , bubble enemy 0.05 Kg / m 3 , the balance is water, and the pH is natural.

[0037] Fermentation conditions:

[0038] The fermentation process is carried out in a 50L fermenter, the initial liquid volume is 50%, the inoculum volume is 6%, the stirring speed is 30...

Embodiment 3

[0044] Embodiment 3: the product preparation of lincomycin

[0045] About 40 L of the fermented liquid obtained in Example 2 was adjusted to 3.0 with oxalic acid, and the acidified liquid was filtered with a plate and frame to obtain 22 L of filtered clear liquid. The filtered clear liquid was adjusted to pH 10.5 with 20% sodium hydroxide solution. Re-filter the alkaline filtrate to ensure the clarification of the alkali solution, add 2 / 5 volume of mixed alcohol, start stirring for 20-30min, and let it stand for stratification. The upper organic phase is subjected to unit operations such as vacuum concentration, crystallization, decolorization, acetone crystallization, and drying to obtain the lincomycin product.

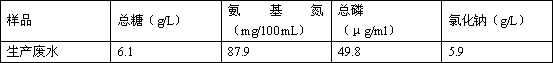

[0046]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com