Preparation method and application of polyester nanofiber modified membrane adsorption material

A polyester nano-fiber modification technology, applied in fiber treatment, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of high non-selective adsorption and regeneration costs, limited wide application, and high preparation costs. Achieve the effects of fast adsorption speed, large adsorption capacity and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) Dissolve 5.1 g of PET in 27 mL of trifluoroacetic acid (TFA) and 3 mL of dichloromethane (CH 2 Cl 2 ) in a mixed solvent, TFA / CH 2 Cl 2 The volume ratio is 9:1, and the electrospinning solution is uniform and transparent under constant stirring at room temperature.

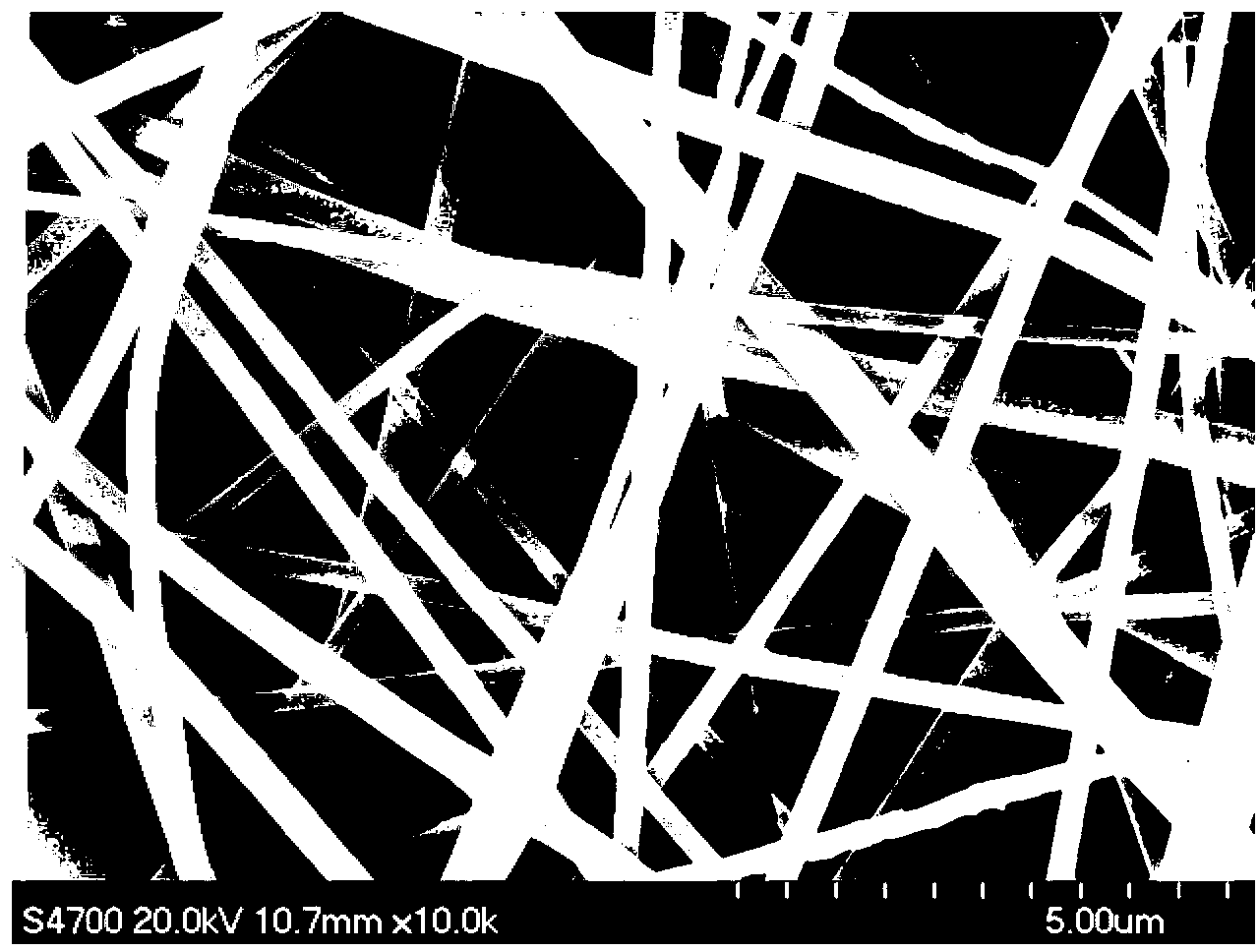

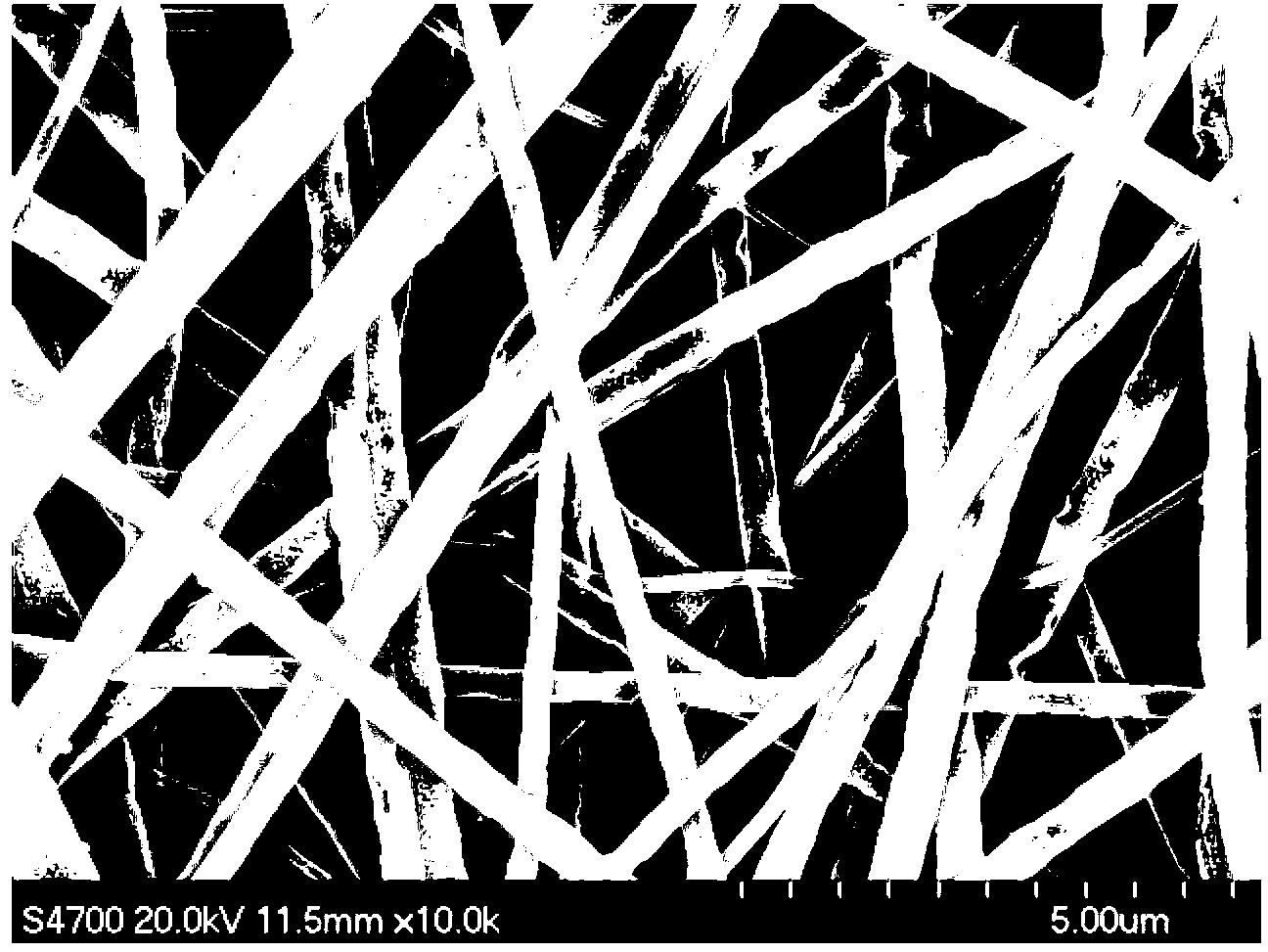

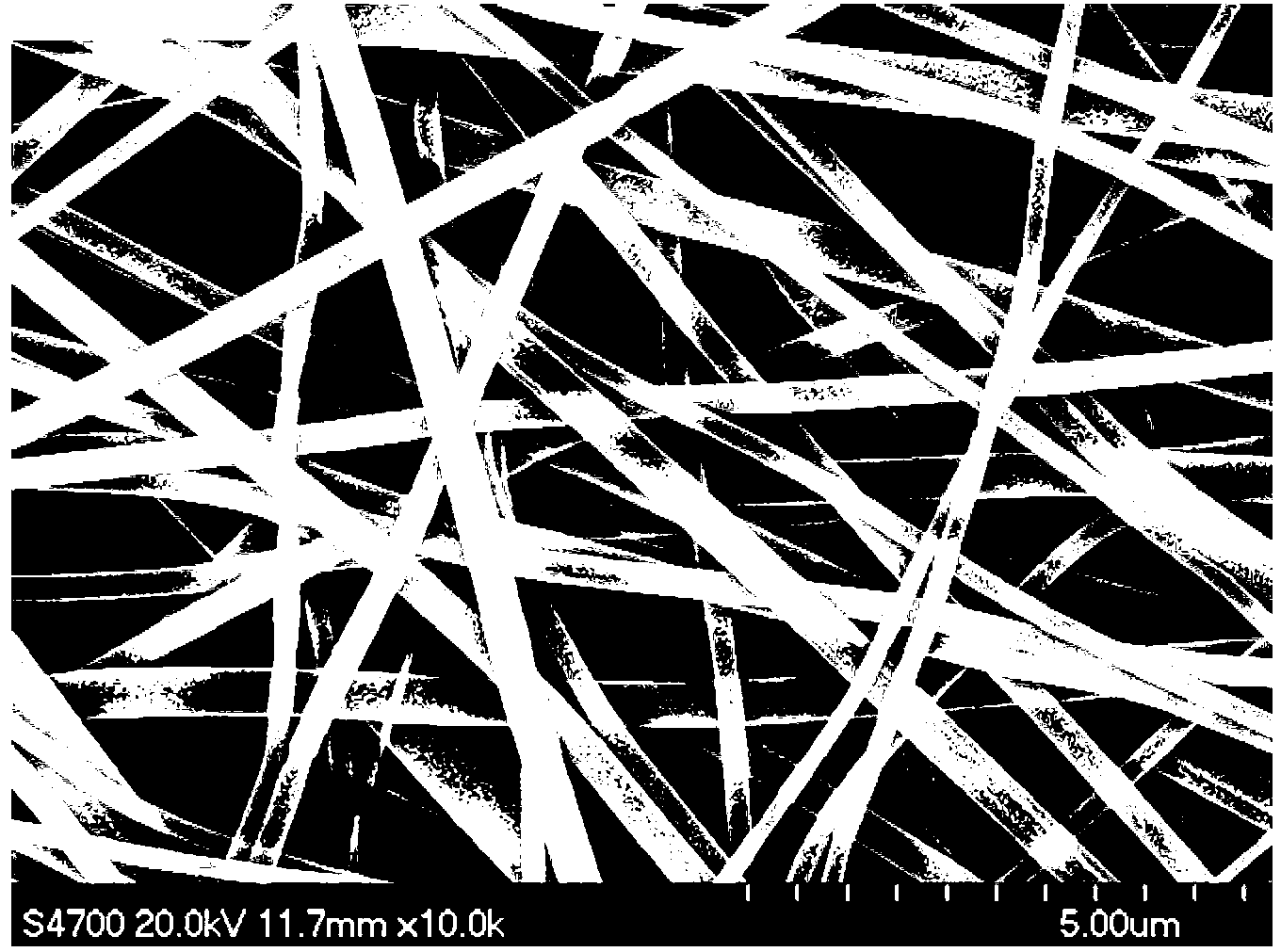

[0030] 2) Put the electrospinning solution in step 1) into the liquid storage tube of the electrospinning device, control the extrusion speed to 0.002mm / s through a micro-injection pump, and the distance from the spinning nozzle to the receiver is 15cm, and spin Electrospinning was performed at a voltage of 25kV, and the spun fiber membrane was received on a collector to obtain a nanofiber membrane. After the fiber film sample was prepared and sprayed with gold, its morphology was observed by scanning electron microscope, and the obtained electron microscope picture was as follows figure 1 As shown, the diameter of the nanofibers constituting the polyester nanofiber film is 307 nm.

[0031] 3) Place...

Embodiment 2

[0035] 1) Dissolve 5.1 g of PET in 27 mL of trifluoroacetic acid (TFA) and 3 mL of dichloromethane (CH 2 Cl 2 ) in a mixed solvent, TFA / CH 2 Cl 2 The volume ratio is 9:1, and the electrospinning solution is uniform and transparent by stirring continuously until uniform.

[0036] 2) Put the electrospinning solution in step 1) into the liquid storage tube of the electrospinning device, control the extrusion speed to 0.002mm / s through a micro-injection pump, and the distance from the spinning nozzle to the receiver is 15cm, and spin Electrospinning was performed at a voltage of 25kV, and the spun fiber membrane was received on a collector to obtain a nanofiber membrane. After the fiber film sample was prepared and sprayed with gold, its morphology was observed by scanning electron microscope, and the obtained electron microscope picture was as follows figure 1 As shown, the diameter of the nanofibers constituting the polyester nanofiber film is 307 nm.

[0037] 3) Place the ...

Embodiment 3

[0041] 1) Dissolve 5.1 g of PET in 27 mL of trifluoroacetic acid (TFA) and 3 mL of dichloromethane (CH 2 Cl 2 ) in a mixed solvent, TFA / CH 2 Cl 2 The volume ratio is 9:1, and the electrospinning solution is uniform and transparent by stirring continuously until uniform.

[0042] 2) Put the electrospinning solution in step 1) into the liquid storage tube of the electrospinning device, control the extrusion speed to 0.002mm / s through a micro-injection pump, and the distance from the spinning nozzle to the receiver is 15cm, and spin Electrospinning was performed at a voltage of 25kV, and the spun fiber membrane was received on a collector to obtain a nanofiber membrane. After the fiber film sample was prepared and sprayed with gold, its morphology was observed by scanning electron microscope, and the obtained electron microscope picture was as follows figure 1 As shown, the diameter of the nanofibers constituting the polyester nanofiber film is 307 nm.

[0043] 3) Place the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com