Method for producing high-quality collagen oligopeptide by using fish skin or fishbone

A technology of collagen and oligopeptides, which is applied in the field of preparation of collagen peptides, can solve the problems that the utilization rate of raw protein cannot be improved, the fishy smell cannot be completely removed, and the utilization rate of protein is low, so as to improve the utilization rate of hydrolysis and The degree of hydrolysis, reducing the amount of enzyme used, and improving the effect of enzymatic hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

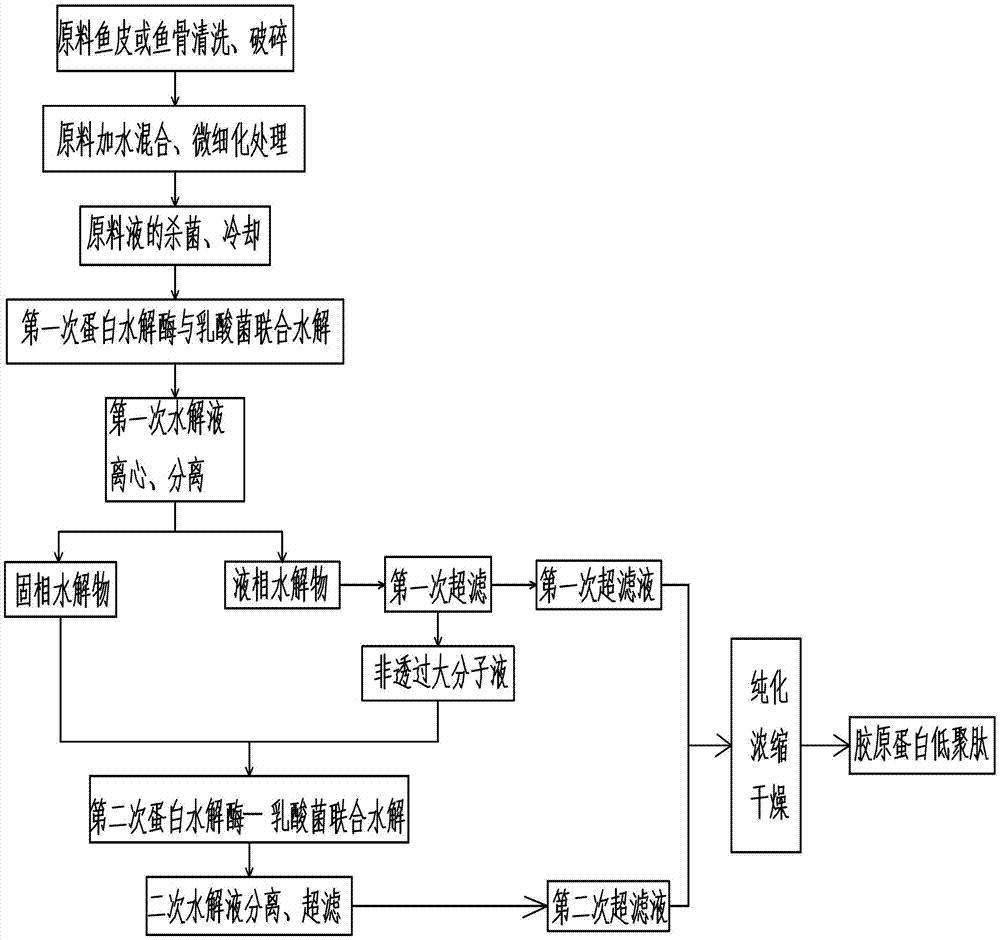

Image

Examples

Embodiment 1

[0033] Embodiment one: described a kind of method of producing high-quality collagen oligopeptide with fish skin or fish bone, it is characterized in that concrete steps are as follows:

[0034] (1) The fresh tilapia skin conforming to GB18406 National Pollution-free Aquatic Product Hygienic Requirements is washed, crushed, mixed with water at a weight ratio of 1:12, and the mixture is passed through a colloid mill for micronization treatment, so that the raw fish skin or The fish bones are fully dispersed and evenly made into a raw material solution with a protein concentration of about 2%;

[0035] (2) The raw material liquid prepared in the step (1) is sterilized at a high temperature of 120°C for 5 seconds, and then cooled to 50°C by a plate cooler;

[0036] (3) Add alkaline proteolytic enzyme and Lactobacillus delbrueckii (L.delbrueckii) to the raw material liquid after the sterilization treatment in step (2) to carry out the first hydrolysis, the condition of the first h...

Embodiment 2

[0043] A method for producing high-quality collagen oligopeptides with fish skin or fish bones is characterized in that the specific steps are as follows:

[0044] (1) Freshwater silver carp will produce a large number of by-products in the process of processing surimi-fresh fish skin and fish bone residue, which will be produced during the processing of silver carp surimi that meets the national pollution-free aquatic product hygiene requirements of GB18406 Fresh silver carp skin and fish bone dregs are washed and crushed, mixed with water at a weight ratio of 1:16, and the mixture is finely processed through a colloid mill, so that the raw fish skin or fish bones are fully dispersed and evenly prepared to produce a protein concentration of 3-5% raw material solution;

[0045] (2) The raw material liquid prepared in the step (1) is sterilized under normal pressure at 90°C for 90 seconds, and then cooled to 42°C by a tube cooler;

[0046] (3) add alkaline protease, neutral pr...

Embodiment 3

[0053] A method for producing high-quality collagen oligopeptides with fish skin or fish bones is characterized in that the specific steps are as follows:

[0054] (1) Wash the dried skin of deep-sea cod that meets the hygiene requirements of national pollution-free aquatic products in GB18406, soak it in cold water at 10°C overnight, then crush the soaked wet skin of deep-sea cod and mix it with water at a weight ratio of 1:18 , wherein the weight of sea cod fish skin adopts its dry weight, and the mixture is passed through a colloid mill to carry out micronization treatment, so that the raw fish skin or fish bones are fully dispersed and evenly prepared into a raw material solution with a protein concentration of 3.5%;

[0055] (2) The raw material liquid prepared in the step (1) is sterilized at a high temperature of 110° C. for 10 seconds, and then cooled to 45° C. with a plate cooler;

[0056] (3) Add alkaline protease, pepsin, Lactobacillus delbrueckii (L.delbrueckii), a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com