Nano-lithium iron phosphate material suitable for high rate power battery and preparation method thereof

A lithium iron phosphate and power battery technology, applied in the field of nano-lithium iron phosphate materials, can solve problems such as low electronic conductivity and ionic conductivity, reduced battery capacity, and poor material rate characteristics, and achieve improved conductivity and electrical performance. , The effect of high product controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Put ferrous oxalate (1177g), lithium carbonate (263g), ferric dihydrogen ammonium phosphate (1250g), glucose (500g), isopropanol (6000g) in a ball mill for 3 hours, and then ultrafine in a sand mill Grind for 3 hours, then dry in a double-cone vacuum dryer for 4 hours to obtain the precursor. The D50 of the precursor is 0.4~0.8um; Melt and burn at 700°C for 20 hours, cool to room temperature at a cooling rate of 4°C / min to obtain lithium iron phosphate; then pass through a jet mill for 10 minutes, and finally mix with a double-helix conical mixer for 2 hours to obtain iron phosphate Lithium products.

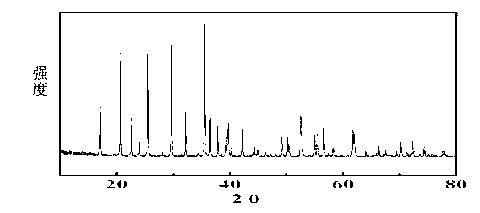

[0035] Such as figure 1 As shown, the X-ray diffraction analysis results show that the prepared lithium iron phosphate is olivine type lithium iron phosphate;

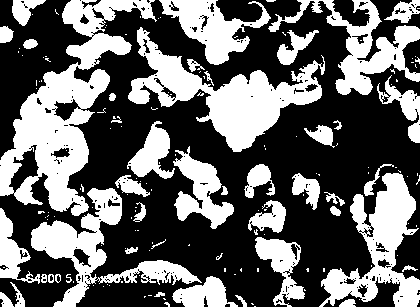

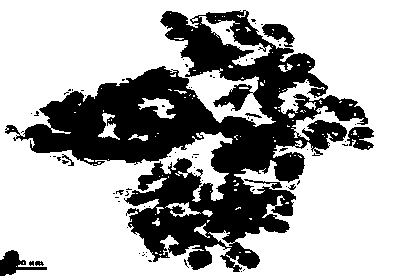

[0036] figure 2 Scanning electron microscope photos show that the primary particles are between 50~100nm, the particles are spherical, and the aspect ratio is 1.3~1. image 3 Transmission electron microscope ...

Embodiment 2

[0041] Put ferrous oxalate (1798g), lithium dihydrogen phosphate (1046g), glucose (400g), and isopropanol (6000g) in a ball mill for 3 hours, then grind them ultrafinely in a sand mill for 3 hours, and then grind them in a double Dry in a cone vacuum dryer for 4 hours to obtain the precursor, the precursor D50 is 0.4~0.8um; then use nitrogen as the protective gas in a pusher furnace, heat up at a heating rate of 2°C / min, and burn at a constant temperature of 720°C for 20 Hours, cooled to room temperature at a cooling rate of 4°C / min to obtain lithium iron phosphate; then pulverized by a jet mill for 10 minutes, and finally mixed for 2 hours by a double-helix conical mixer to obtain a finished product of lithium iron phosphate. The synthesized LiFeP04 / The C material and metal lithium sheet were assembled into a test battery. When discharged at a rate of 1C, the reversible specific capacity reached 153mAh / g.

Embodiment 3

[0043] Put ferrous oxalate (1750g), lithium dihydrogen phosphate (1046g), glucose (400g), niobium oxide (18g), and isopropanol (6000g) in a ball mill for 3 hours, and then grind them ultra-finely in a sand mill 3 hours, and then dried in a double-cone vacuum dryer for 4 hours to obtain the precursor. The D50 of the precursor is 0.4~0.8um; Melting at a constant temperature of 720°C for 20 hours, cooling to room temperature at a cooling rate of 4°C / min to obtain lithium iron phosphate; then pulverized by a jet mill for 10 minutes, and finally mixed for 2 hours by a double-helix conical mixer to obtain lithium iron phosphate The finished product, the synthesized LiFeP04 / C material and metal lithium sheet are assembled into a test battery, and the reversible specific capacity reaches 155mAh / g when discharged at a rate of 1C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com