Immobilized lipase and preparation method and application thereof

A technology for immobilizing lipase and lipase, which is applied in the direction of immobilization on or in inorganic carriers, hydrolase, chemical industry, etc., can solve problems such as loss of enzyme activity, improve catalytic efficiency, improve mass transfer rate, avoid the effect of reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

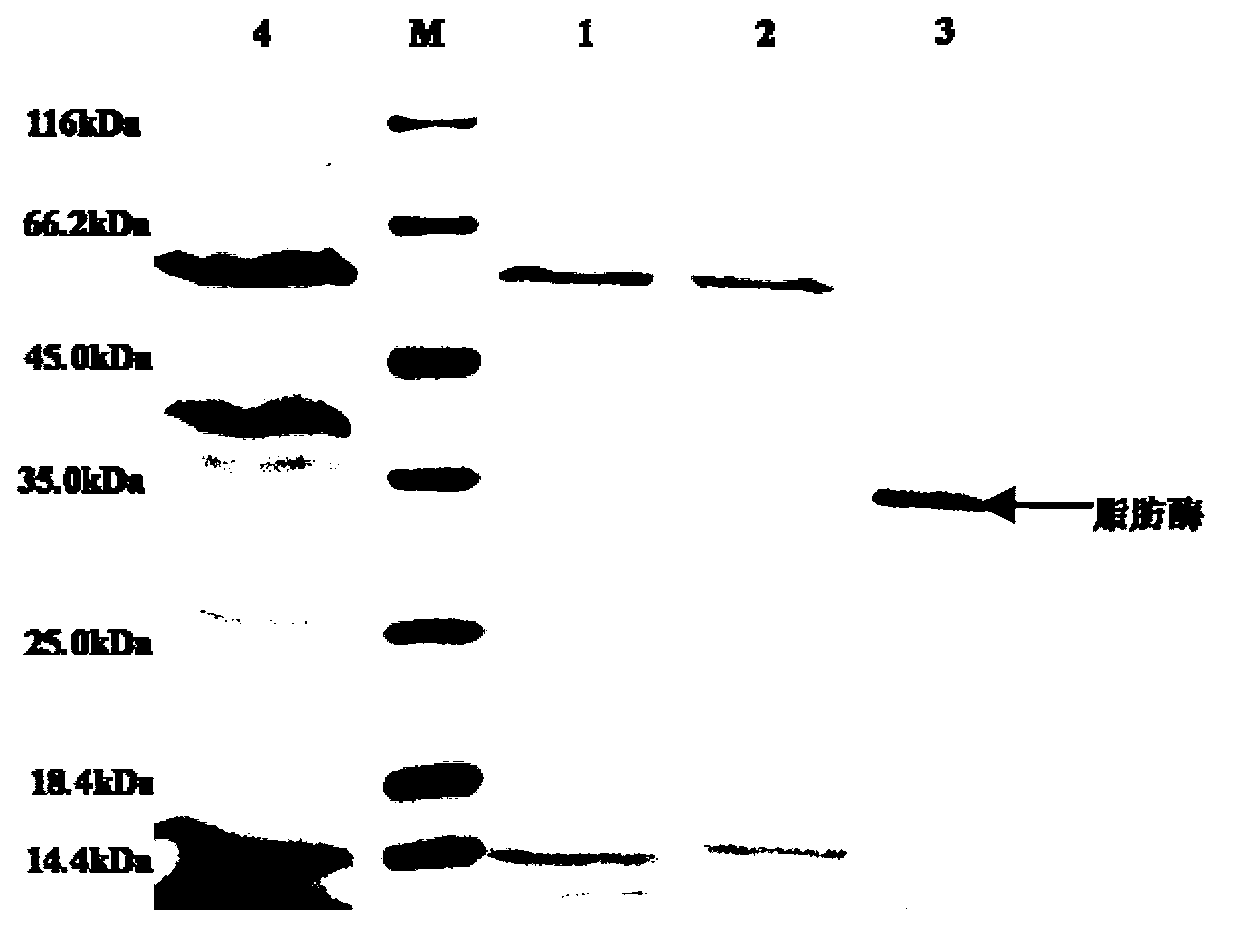

[0056] This experiment illustrates the preparation process of lipase crude enzyme solution.

[0057] by Burkholderia ambifaria YCJ01 (preservation number CCTCC NO: M 2011058, patent publication number is CN102329745A, patent application number is 201110211402.2) is a production strain, in a 3L fermentation medium (medium is peptone 5g / L, yeast powder 5g / L, urea 5 g / L, olive oil 5ml / L, K 2 HPO 4 2g / L, MgSO 4 ·7H 2 O 0.5g / L, Triton X-100 0.5mL / L), inoculated at 5% inoculum size, and then cultured at 150rpm and 30°C for 12h, then increased the stirring speed to 300rpm until the entire fermentation At the end of the process, an antifoaming agent was added to prevent foam generation as appropriate during the fermentation process, and cultured at 300 rpm for 48 hours to obtain lipase YCJ01 fermentation broth. The lipase fermentation broth was centrifuged, and the supernatant was concentrated by ultrafiltration on ice through a GE 10kDa ultrafiltration membrane to obtain a cr...

Embodiment 2

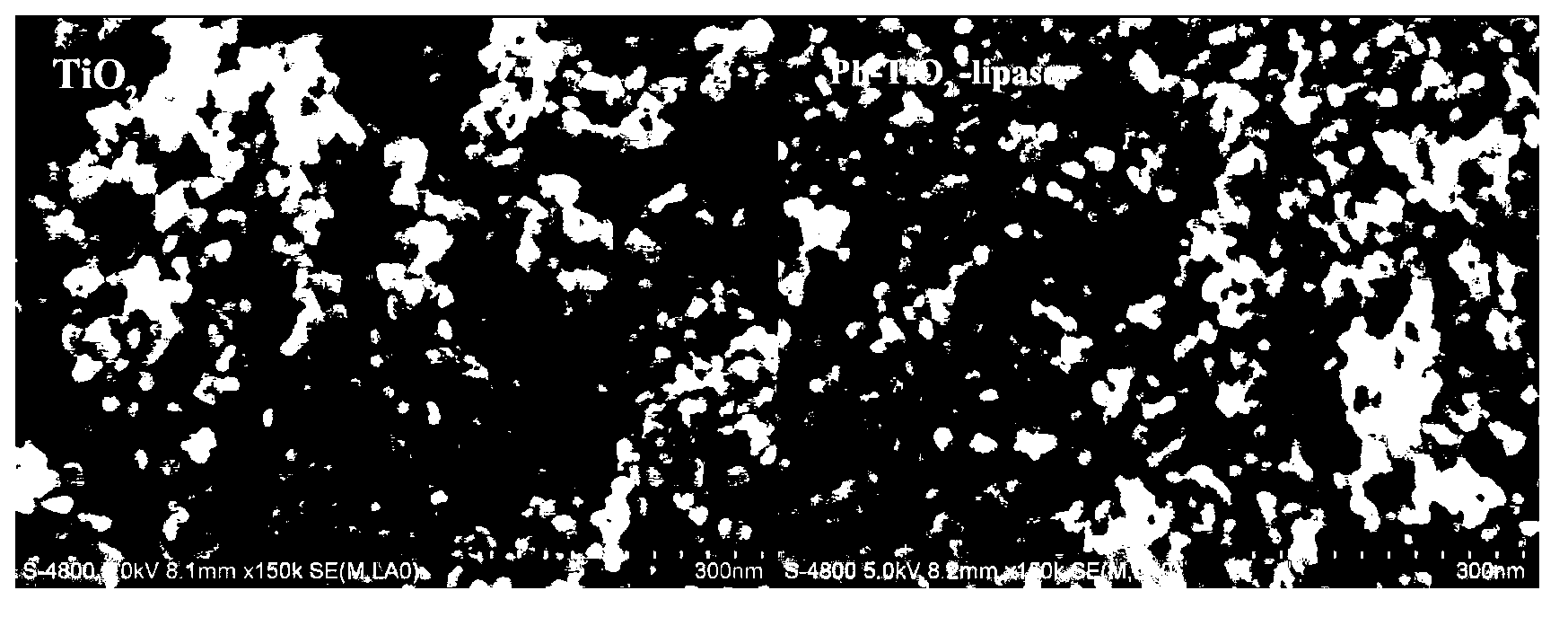

[0062] This experiment demonstrates that mesoporous TiO 2 Surface pretreatment process.

[0063] Weigh about 2g of mesoporous titanium dioxide powder into a 250mL round bottom flask, add about 100mL of a mixed solution of concentrated sulfuric acid / 30% hydrogen peroxide (V / V=70 / 30) to it, and magnetically Stir, heat and reflux for 1 hour, then cool down naturally, centrifuge the mixture, discard the supernatant, wash the precipitate with deionized water until neutral, and finally dry the precipitate in a vacuum oven at 120°C for 12 hours to ensure complete water removal , to get pretreated mesoporous TiO 2 .

Embodiment 3

[0065] This experiment demonstrates the modification of mesoporous TiO with 3-aminopropyltriethoxysilane 2 and the preparation of immobilized enzymes.

[0066] Weigh 500 mg of the above-mentioned pretreated mesoporous titanium dioxide into a 100 mL round bottom flask, add 100 mL of toluene, preheat at 70 °C for 10 min, then add 0.25 mmol of 3-aminopropyltriethoxysilane, in N 2 Under protection, heat to reflux for 8h. After the reaction, the supernatant was discarded by centrifugation, and the precipitate was washed with toluene, acetone, and ethanol respectively to remove the silane coupling agent that did not react successfully. Finally, dry in a vacuum oven at 70°C for 12 hours to obtain 3-aminopropyltriethoxysilane-modified mesoporous TiO 2 .

[0067] Accurately weigh the above-mentioned 3-aminopropyltriethoxysilane modified mesoporous TiO 2 100mg in a 100mL beaker, measure 5mL of the above-mentioned concentrated lipase crude enzyme solution, dilute it to 5 times with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vitality | aaaaa | aaaaa |

| Vitality | aaaaa | aaaaa |

| Vitality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com