Preparation method of nanosphere silicon with silicon-hydrogen shell

A nanosphere and silicon-hydrogen technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of irregular nanoparticle shapes, different particle shapes, and environmental pollution, and achieve enhanced antioxidant capacity, Uniform size to avoid the effect of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

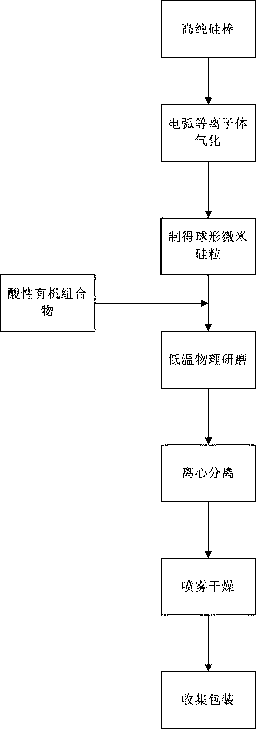

Method used

Image

Examples

Embodiment 1

[0039] Nitrogen gas is introduced into the DC arc plasma generator, the silicon rod is loaded into the anode of the generator and becomes a part of the anode, and the voltage is set to 300 V, the current is 16.7 A, and the voltage is reduced to 12 V when discharging, The current was increased to 250 A, and the time was continued for 240 minutes to obtain spherical silicon particles of 80 microns.

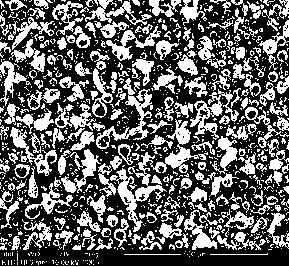

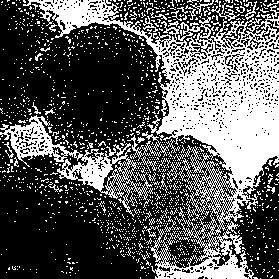

[0040] Physically grind the micron-sized spherical silicon obtained in step 1 under the protection of nitrogen, using agate stone as the ball material for physical grinding, the particle size is mixed in different proportions within the range of 1-10 mm, and the speed of ball milling is 200RPM. At the same time, 60 parts of isopropanol, 20 parts of acetone and 5 parts of hydrofluoric acid were introduced, and the temperature was controlled at 60 0 C, the time is controlled at 2 hours. Under the dual effects of physical grinding and chemical grafting reaction, micron-sized nano-sili...

Embodiment 2

[0043] Argon gas is introduced into the DC arc plasma generator, the silicon rod is loaded into the anode of the generator and becomes a part of the anode, and the voltage is set to 300 V, the current is 16.7 A, and the voltage is reduced to 15 V when it is discharged. The current was increased to ~250 A for 200 minutes to produce spherical silicon particles of 65 μm.

[0044]The micron-sized spherical silicon obtained in step 1 under the protection of nitrogen is physically ground, and silicon carbide is used as the ball material for physical grinding. The particle size is mixed in different proportions within the range of 1-10 mm, and the speed of ball milling is 300RPM. Pass into 65 parts of ethanol simultaneously, the toluene of 25 parts and the nitric acid of 6 parts, temperature is controlled at 60 0 C, the time is controlled at 4 hours. Under the dual effects of physical grinding and chemical grafting reaction, the micron-sized nano-silicon particles form regular nano-...

Embodiment 3

[0047] Nitrogen gas is introduced into the DC arc plasma generator, the silicon rod is loaded into the anode of the generator and becomes a part of the anode, and the voltage is set to 300 V, and the current is 16.7 A. Ramp up to ~250 A for 160 min to produce 50 µm spherical silica particles.

[0048] The micron-sized spherical silicon obtained in step 1 under the protection of nitrogen is physically ground, and zirconia is used as the ball material for physical grinding. The particle size is mixed in different proportions within the range of 1-10 mm, and the speed of ball milling is 200RPM. At the same time, 75 parts of isopropanol, 30 parts of n-dodecene and 8 parts of hydrochloric acid were introduced, and the temperature was controlled at 60 0 C, the time is controlled at 7 hours. Under the dual effects of physical grinding and chemical grafting reaction, micron-sized nano-silicon particles form regular-shaped nano-sized spherical silicon particles with an average particl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com