Pseudomonas SYA-1 for degrading triethylamine and application of pseudomonas SYA-1

A technology of SYA-1 and Pseudomonas, applied in the direction of bacteria, enzymes, immobilized enzymes, etc., can solve the problems of high cost, secondary pollution, etc., achieve low production costs, reduce wastewater treatment costs, and protect the ecological environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1 Isolation and identification of triethylamine-degrading strain SYA-1

[0023] Take 1.0ml of triethylamine-enriched bacterial solution, add 9.0ml of sterile water, and mix well to make 10 -1 The rich solution, and then draw 1.0ml prepared 10 -1 The enrichment solution was added to 9.0ml sterile water, mixed thoroughly to make 10 -2 The enrichment solution, and so on, carry out gradient dilution on the enrichment solution. Draw 0.1ml of the diluted solution of each gradient and spread it on the inorganic salt solid medium containing 100mg / L triethylamine. The formula is: each liter contains 1.5 g K 2 HPO 4 , 0.5 g KH 2 PO 4 , 0.2 g MgSO 4 ×7H 2 O, 1.0 g NaCl, 1.0 g (NH 4 ) 2 SO 4 , 20g agar, pH 7.0, cultured at 30°C for 7 days. After 7 days, pick a single colony from the above inorganic salt solid medium, culture in 5ml LB liquid medium for 24 hours, centrifuge at 8000r / min for 2min, pour off the supernatant, add 5ml of sterile Shake well with water,...

Embodiment 2

[0024] Example 2 The method for preparing immobilized pellets from bacterial strain SYA-1

[0025] 1) Use an inoculation loop to pick a small amount of bacterial strains on the slant medium and inoculate them in LB liquid medium at 30°C and 160r / min for shaking culture to the logarithmic phase;

[0026] 2) Centrifuge the above cultured bacterial solution at 8000r / min for 2min, discard the supernatant, add the same volume of sterile water, shake well and centrifuge at 8000r / min for 2min, wash twice in this way, and use the same volume Suspended in sterile water to make a bacterial fluid.

[0027] 3) Mix 1ml of bacterial liquid with 20ml of 4% sodium alginate solution at room temperature, then drop the mixture into 3% CaCl at room temperature with a syringe 2 The solution was cross-linked and calcified at 4°C for 6 hours to obtain calcium alginate gel-immobilized beads, which were washed twice with sterile water and stored at 4°C for later use.

[0028] The LB medium described...

Embodiment 3

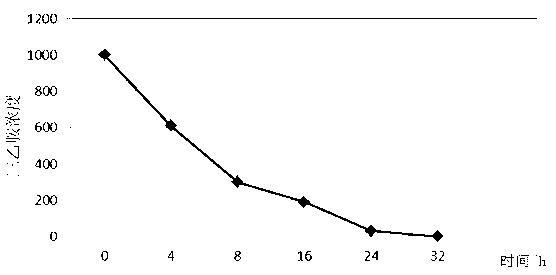

[0029] The application method of embodiment 3 immobilized bead in triethylamine degradation

[0030] First, aerate the immobilized pellets in wastewater for 12 hours to activate. During the activation process, the water temperature is 28±2°C, the aeration rate is 1.2L / min, and then the temperature is 28±2°C, and the pH value is 6.8-7.2. Under conditions, under the situation that triethylamine influent concentration is lower than 1000mg / L, every liter of triethylamine waste water takes the immobilized pellet prepared in embodiment 2 of 185ml to process, and simultaneously, hydraulic retention time is 32h, as image 3 Shown, in this case the removal rate of triethylamine is more than 97%, and better removal effect is arranged; And Figure 4The removal of triethylamine for different influent concentrations is shown. The research shows that the removal rate of triethylamine decreases with the increase of influent concentration. When the concentration of triethylamine in influent i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com